- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

-

This guide details the LSAW steel pipe manufacturing process, comparing UOE and JCOE forming methods while highlighting the rigorous welding, expansion, and quality control steps Finego Steel uses to ensure project safety.2026-01-29

This guide details the LSAW steel pipe manufacturing process, comparing UOE and JCOE forming methods while highlighting the rigorous welding, expansion, and quality control steps Finego Steel uses to ensure project safety.2026-01-29 -

This comprehensive guide breaks down API 5L pipe specifications, comparing the advantages of api 5l seamless pipe versus welded options and detailing the critical differences between pipe grades and PSL1 vs. PSL2 standards to ensure project safety.2026-01-27

This comprehensive guide breaks down API 5L pipe specifications, comparing the advantages of api 5l seamless pipe versus welded options and detailing the critical differences between pipe grades and PSL1 vs. PSL2 standards to ensure project safety.2026-01-27 -

This guide details the manufacturing process and critical advantages of seamless carbon steel pipes, explaining how to distinguish between major grades like ASTM A106 and API 5L to ensure safety in high-pressure industrial projects.2026-01-20

This guide details the manufacturing process and critical advantages of seamless carbon steel pipes, explaining how to distinguish between major grades like ASTM A106 and API 5L to ensure safety in high-pressure industrial projects.2026-01-20 -

This guide explores the essential types of oil and gas pipe fittings, including elbows and reducers, while providing expert insights on material selection and connection methods to ensure the safety and longevity of high-pressure pipeline projects.2026-01-15

This guide explores the essential types of oil and gas pipe fittings, including elbows and reducers, while providing expert insights on material selection and connection methods to ensure the safety and longevity of high-pressure pipeline projects.2026-01-15 -

This article provides a comprehensive guide to BS 1387 galvanized steel pipes, detailing their weight classes (Light, Medium, Heavy), the hot-dip galvanizing process for corrosion resistance, and their critical advantages over plastic for industrial water and gas systems.2026-01-08

This article provides a comprehensive guide to BS 1387 galvanized steel pipes, detailing their weight classes (Light, Medium, Heavy), the hot-dip galvanizing process for corrosion resistance, and their critical advantages over plastic for industrial water and gas systems.2026-01-08 -

This guide explains the manufacturing process, strict size tolerances, and key benefits of precision steel pipes, helping you choose the right high-quality materials for your hydraulic and construction projects.2025-12-30

This guide explains the manufacturing process, strict size tolerances, and key benefits of precision steel pipes, helping you choose the right high-quality materials for your hydraulic and construction projects.2025-12-30 -

This comprehensive guide explains the technical specifications, manufacturing types (Type E vs. Type F), and specific grades of ASTM A53 welded steel pipe, helping procurement managers select the most cost-effective solution for structural and low-pressure applications.2025-12-23

This comprehensive guide explains the technical specifications, manufacturing types (Type E vs. Type F), and specific grades of ASTM A53 welded steel pipe, helping procurement managers select the most cost-effective solution for structural and low-pressure applications.2025-12-23 -

This guide details why the BS 1387 galvanized steel pipe remains the industry standard for reliable water and gas transport, explaining wall thickness classifications, galvanizing quality (Class B vs. Class C), and how to source integrated piping solutions from Finego Steel.2025-12-16

This guide details why the BS 1387 galvanized steel pipe remains the industry standard for reliable water and gas transport, explaining wall thickness classifications, galvanizing quality (Class B vs. Class C), and how to source integrated piping solutions from Finego Steel.2025-12-16 -

This comprehensive guide explains why hot dip galvanized steel pipe is the superior choice for corrosion resistance, detailing its unique manufacturing process, lifespan advantages, and critical differences from cold galvanizing to ensure long-term project safety.2025-12-11

This comprehensive guide explains why hot dip galvanized steel pipe is the superior choice for corrosion resistance, detailing its unique manufacturing process, lifespan advantages, and critical differences from cold galvanizing to ensure long-term project safety.2025-12-11 -

This guide details the specific types, grades, and testing standards of ASTM A53 steel pipe to help procurement managers select the ideal material for pressure and structural projects while avoiding costly compliance mistakes.2025-12-09

This guide details the specific types, grades, and testing standards of ASTM A53 steel pipe to help procurement managers select the ideal material for pressure and structural projects while avoiding costly compliance mistakes.2025-12-09 -

This article compares the structural differences, manufacturing processes, and ideal applications of I-beams versus H-beams, helping project managers choose the correct steel profile for safety and cost efficiency.2025-12-04

This article compares the structural differences, manufacturing processes, and ideal applications of I-beams versus H-beams, helping project managers choose the correct steel profile for safety and cost efficiency.2025-12-04 -

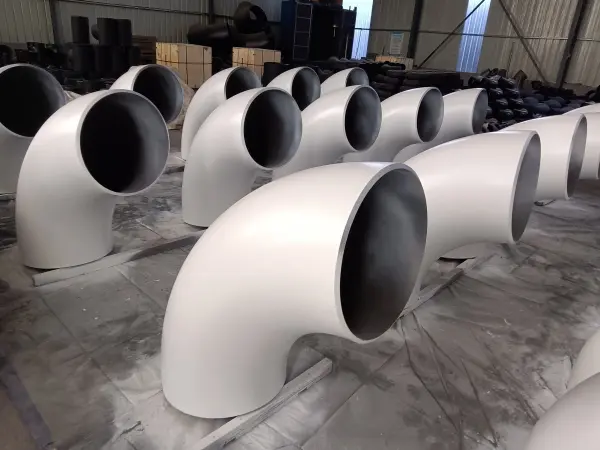

Explore essential pipe fittings in the oil and gas industry, focusing on elbows, tees, reducers, and valves to ensure pipeline efficiency and safety.2025-11-20

Explore essential pipe fittings in the oil and gas industry, focusing on elbows, tees, reducers, and valves to ensure pipeline efficiency and safety.2025-11-20 -

The 90 degree elbow is a vital piping component used to redirect flow, with applications in plumbing, industrial, and HVAC systems. Our high-quality steel elbows provide durability and efficiency.2025-11-18

The 90 degree elbow is a vital piping component used to redirect flow, with applications in plumbing, industrial, and HVAC systems. Our high-quality steel elbows provide durability and efficiency.2025-11-18 -

Discover the key distinctions between ASTM A53 Grade A and Grade B pipes, focusing on their applications, mechanical properties, and costs.2025-11-11

Discover the key distinctions between ASTM A53 Grade A and Grade B pipes, focusing on their applications, mechanical properties, and costs.2025-11-11 -

This article compares ASTM A106 and A53 steel pipes, highlighting their specifications, mechanical properties, and ideal applications to help engineers and buyers choose the right pipe.2025-11-04

This article compares ASTM A106 and A53 steel pipes, highlighting their specifications, mechanical properties, and ideal applications to help engineers and buyers choose the right pipe.2025-11-04

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from,This behavior is in compliance with the user consent policy.

Language

Language