- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What Are the Essential Specifications of API 5L Pipes for Your Project?

Pipeline failures cause massive delays and financial loss for EPC companies. You need reliable materials, but navigating complex API standards can be overwhelming for even experienced buyers. API 5L specifications cover seamless and welded steel pipes for pipeline transportation systems in the petroleum and natural gas industries. They define strict chemical and mechanical properties across various grades like X42 to X70. Understanding these standards ensures you select the correct api 5l seamless pipe or welded option for safety and efficiency.

Choosing the wrong grade or specification isn't just a compliance issue; it is a major safety risk. I have seen many project managers struggle to balance cost and technical requirements. Let me walk you through exactly what you need to know to make the right purchase.

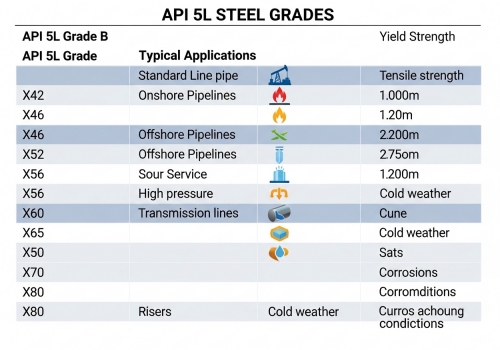

Which API 5L Grade Is Right for Your Application?

Selecting the wrong grade leads to structural weakness or wasted budget on over-specification. You must balance yield strength with cost efficiency to ensure project success. Grades like Grade B, X42, X52, X60, X65, and X70 represent the minimum yield strength of the pipe. The number following the "X" indicates strength in kilopounds per square inch (ksi). Your choice depends on the internal pressure, environment, and specific project design requirements defined by your engineering team.

Understanding the "X" Grades

At Finego Steel, I often help clients decode these grade names. The system is actually quite logical. The letter represents the grade, and the number represents the Minimum Yield Strength. For example, an X52 pipe has a minimum yield strength of 52,000 psi. As you move up in grades, from Grade B to X70 or even X80, the steel becomes stronger. This allows you to use thinner walls to hold the same amount of pressure. This can save you money on tonnage costs. However, higher grades can be harder to weld. You need to find the sweet spot between material cost and installation difficulty.

Chemical Composition Matters

It is not just about strength. The chemical mix changes with each grade. Higher grades often use micro-alloys like Vanadium or Niobium. These elements refine the grain of the steel. This makes the pipe tough but still flexible enough to handle ground movement. Here is a quick reference table I use when consulting with my EPC partners:

| Grade | Min. Yield Strength (PSI) | Min. Tensile Strength (PSI) | Typical Application |

|---|---|---|---|

| Grade B | 35,000 | 60,000 | Low-pressure fluid lines, general structure |

| X42 | 42,000 | 60,000 | Standard line pipe for oil and gas |

| X52 | 52,000 | 66,000 | Medium to high-pressure transmission |

| X60 | 60,000 | 75,000 | Long-distance pipelines |

| X65 | 65,000 | 77,000 | Offshore and high-stress environments |

| X70 | 70,000 | 82,000 | High-pressure gas transmission |

Should You Choose Seamless or Welded API 5L Pipes?

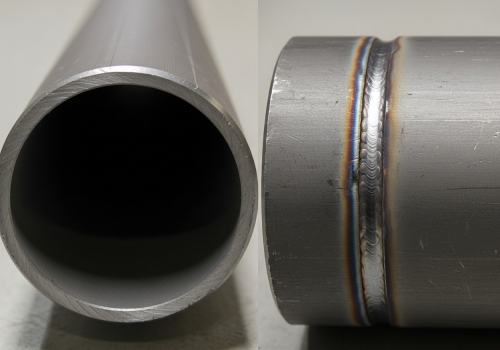

The debate between seamless and welded pipes often confuses buyers. Making the wrong choice affects pressure tolerance and project longevity in critical infrastructure. An api 5l seamless pipe is manufactured from a solid billet, offering uniform strength for high-pressure environments without any weld seam. Welded pipes (like ERW, LSAW, or SSAW) are more cost-effective for larger diameters. Your decision relies on pressure ratings, diameter needs, and budget constraints.

The Case for Seamless Pipes

I always tell my customers that api 5l seamless pipe is the gold standard for high pressure. Because it is made from a solid round billet that is heated and pierced, there is no seam. The seam is usually the weakest part of a pipe. Without it, the pipe can handle higher stress and is less likely to fail. This is why you see seamless pipes used in critical risers or subsea applications. However, seamless pipes have limits. It is very difficult and expensive to make them in very large diameters (usually above 24 inches). If your project needs a 48-inch pipeline, seamless is likely not an option.

| Type | Manufacturing Method | Size Availability | Best For |

|---|---|---|---|

| Seamless (SMLS) | Extruded from solid billet | Small to Medium (up to 24") | High pressure, critical safety areas |

| ERW | High-frequency electrical weld | Small to Medium (up to 24") | Onshore oil/gas, lower cost projects |

| LSAW | Plate bent and welded | Medium to Large (16" - 64") | Heavy wall, high pressure, offshore |

| SSAW | Coil wound spirally | Large to Extra Large (up to 100"+) | Long-distance transmission, piling |

What Is the Difference Between PSL1 and PSL2?

Ignoring the Product Specification Level (PSL) is a common procurement mistake. It can lead to material rejection during inspection or catastrophic failure in sour services. PSL1 is the standard quality level for general lines, covering basic mechanical properties. PSL2 involves stricter chemical limits, mandatory notch toughness testing, and tighter mechanical properties. For sour service, offshore lines, or high-stress applications, PSL2 is almost always the mandatory requirement to ensure safety.

Why PSL2 Costs More but Is Worth It

At Finego Steel, we often get asked why PSL2 is more expensive. It comes down to quality control and raw materials. PSL1 is loose. It allows for a wider range of chemical elements. You can use it for standard water lines or low-pressure gas. PSL2 is strict. It places a cap on the Carbon Equivalent. This is vital for weldability. If you need to weld pipes in the field, PSL2 ensures the weld won't crack easily. Furthermore, PSL2 requires traceability. You need to know exactly where that steel came from.

Critical Testing Differences

The biggest difference I see in the factory is the testing.

· NDT (Non-Destructive Testing): For PSL2, we must inspect the entire weld seam and the pipe body more rigorously using ultrasonic or X-ray methods. If you are buying for a project in Germany or for a major oil major like Shell or Exxon, they will almost surely demand PSL2. Do not try to save money here if the specifications are tight.

| Feature | PSL1 | PSL2 |

|---|---|---|

| Chemical Composition | Standard limits | Stricter limits (Low Carbon) |

| Impact Testing (CVN) | Not required | Mandatory |

| Repair by Welding | Permitted | Prohibited (Body), Limited (Weld) |

| Certification | Traceable | Fully Traceable |

| Main Use | General Services | Severe Service / Sour Service |

Conclusion

Understanding API 5L grades, the choice between api 5l seamless pipe and welded types, and the strict differences between PSL1 and PSL2 ensures safe, cost-effective project execution.

Language

Language