- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Quality Control

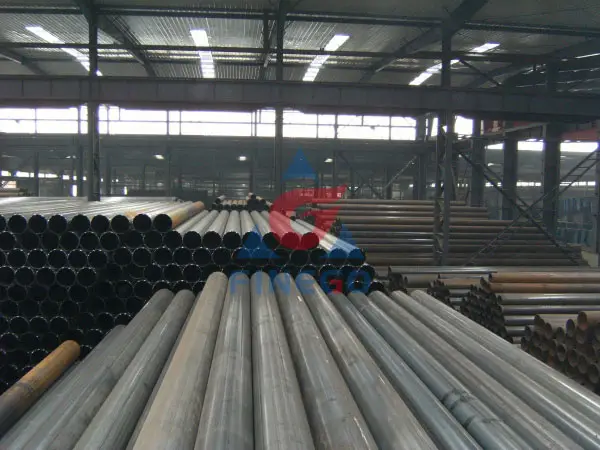

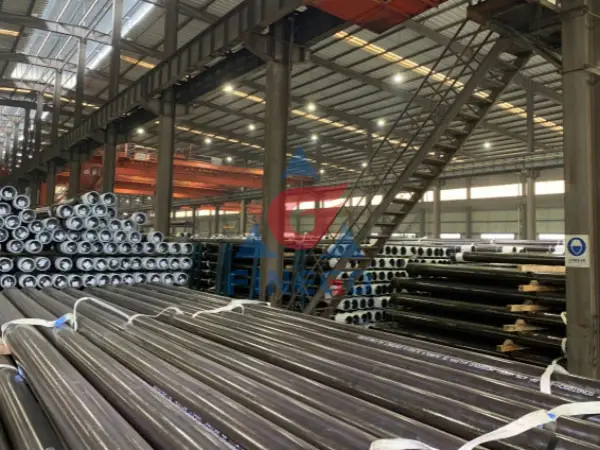

SEAMLESS TUBE PRODUCTION LINE

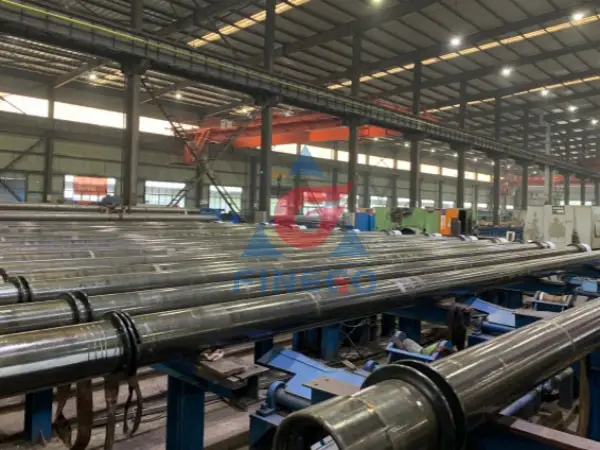

Hot-rolled production line

At present, we have 3 sets of hot-rolled seamless steel pipe production lines with an annual production capacity of 1.35 million tons. The physical and chemical laboratory conducts various physical and chemical tests on steel pipes, and is equipped with eddy current flaw detectors, magnetic flux leakage detectors and ultrasonic flaw detectors. It is used for high, medium and low pressure seamless steel pipes and oil casings. All-round inspection measures can meet various standard test and inspection requirements for steel pipes.

Φ114 two-roll continuous rolling pipe production line (MPM) : Φ32 ~ Φ114 × 3 ~ 30 mm

Φ180 three-roll continuous rolling pipe production line (PFQ) : Φ108 ~ Φ219 × 5 ~ 40mm

Φ273 three-roll continuous rolling pipe production line (PFQ) : Φ177.8 ~ Φ356 × 6 ~ 50.0 mm

In addition, there are 12 thermal expansion production lines, the production size range is: Φ356 ~ Φ1200 × 8 ~ 50.0 mm)

Φ114 two-roll continuous rolling pipe production line (MPM)

The main equipment of the two-roll continuous rolling line is composed of "conical roller piercing machine + 6-stand PQF continuous rolling mill + 14-stand micro tension setting machine". The unit mainly produces high-quality oil pipes with large diameter-to-wall ratio (D/S), Line pipe, structural pipe, boiler pipe, product specification Φ32~114×3~30mm, designed annual output of 300,000 tons

Φ180 three-roll continuous rolling pipe production line (PFQ)

Specification range:

Product diameter: Φ114~ Φ219 × 5 ~ 40mm

Annual production capacity can reach 400,000 tons

For oil casing, line pipe, structural pipe, fluid pipe, boiler pipe, etc.

Φ273 three-roll continuous rolling pipe production line (PFQ)

This series of equipment can produce various steel grade seamless steel pipes with sizes ranging fromΦ177.8 ~Φ356×6 ~ 50.0 mm, covering oil well pipes, line pipes, energy pipes, high pressure boiler pipes, and nuclear power pipes, urban infrastructure pipes, etc. , the annual production capacity can reach 600,000 tons

Heat treatment equipment

Quenching equipment: the maximum heating temperature is 1100°C; the heating temperature difference accuracy is ±10°C; the effective length of the furnace is 13m; the quenching device is internal spray + external shower, the maximum capacity is 120 pieces/hour; Thickness 4.5 ~ 40mm, length 6 ~ 13m. Tempering equipment: the maximum tempering temperature is 800°C; the heating temperature difference accuracy is ±5°C; the effective length of the furnace: 16.7m; the pipe diameter can be 73~219mm, the wall thickness is 4.5~40mm, and the length is 6~13m.

Cold Rolled/Drawn Production Line

Cold rolled mill

There are 10 cold rolling production lines with an annual production capacity of 30,000 tons, including one 280, one 150, one 110, one 90, three 60, and three 30 units;

Product specification: outer diameter Φ20~273mm, wall thickness 1.0~32mm.

Cold drawing mill

8 sets of 10-200 ton hydraulic and chain cold drawing machines;

Product specifications: outer diameter Φ20~273mm, wall thickness 1.0~26mm, length ≤25000mm;

The product has a wide range of sizes and flexible specifications; the outer diameter has high precision and can be produced in small batches.

Pickling and degreasing equipment

The acid degreasing system in extrusion and cold rolling workshops includes 3 sulfuric acid pickling tanks, 3 mixed acid pickling tanks, 2 degreasing tanks, 2 hot water tanks, 4 clean water tanks, 1 whitening tank, and 1 passivation tank , 1 neutralization tank;

The single-tank pickling and single-tank degreasing capacity is 4t/h;

It is equipped with a waste acid recovery system, an acid-containing wastewater treatment system, and an acid mist treatment system.

Annealing furnace

The oxygen-free annealing furnace adopts the method of electric heating and pre-evacuating protective atmosphere isothermal spheroidizing annealing furnace to realize the non-oxidative annealing of the workpiece through the method of preheating the vacuum nitrogen protection before and after. The equipment has the characteristics of low atmosphere consumption, low energy consumption, clean subsequent processing, and fast and uniform heating speed, which greatly shortens the annealing process time, makes the workpiece oxidized and decarburized after annealing, and the depth of the depleted carbon layer is less than 0.05mm.

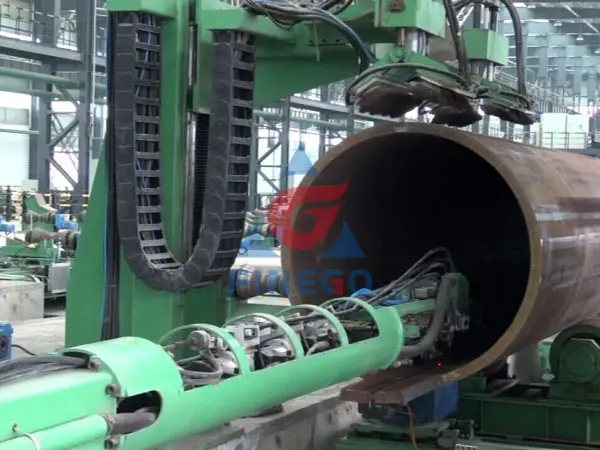

OCTG PIPE PRODUCTION LINE

Casing&Tubing Production Line

The company currently has 4 oil casing production lines, of which 33.4-177.8mm2, 177.8-340mm1, 406-762mm1, can process and supply OD 33.4~762mm, J55, K55, L80, N80-1/Q, P110 , C90, C110, Q125 and other steel grades, oil well pipes, casings, couplings and short connections of various thread types, with an annual processing capacity of 120,000 tons.It can produce oil casing with a diameter of 33.4mm-762mm,processing diameter 33-762mm.Sand control pipes and screens: laser-slotted oil casing, wound wire oil casing, couplings, drill pipes, wire-wound screens, punched screens, slotted screens, and drilling screens.

Hydraulic upsetting press

Hydraulic upsetting press chosen for this production has enough capacity to upset the minimum and maximum tubings from2 3/8 to4 1/2 (from 60.3 mm to 114.3 mm ).

2 sets of hydraulic upsetting presses are placed simultaneously, one set of hydraulic upsetting press is used to finish upsetting to one end of tubing, another set of hydraulic upsetting press used upset another end of tubing, which greatly increase the productivity and efficiency.

Drift mandrel testing machine

After upsetting, drift mandrel testing should be done according to API 5CT standard.

This drift mandrel testing machine is a special equipment for oil pipe diameter quality inspection. It adopts standard diameter gauge to test the cylindricity and straightness of the oil pipe. The oil tubing drifting mandrel testing machine meets the requirement of Table C.31- Standard drift size in API SPEC 5CT standard.

Oil country lathe

Eonomy type flat bed CNC oil country lathe, moderate slant bed CNC oil country lathe and high performance CNC oil country lathe.Economy type flat bed CNC oil country lathe is equipped with double pneumatic chucks, V4 electric turret, SINUMERIK808D or Fanuc 0i-TF CNC system.Moderate slant bed CNC oil country lathe is equipped with double hydraulic chucks, H8 hydraulic turret, Fanuc 0i-TF CNC system. The productivity is 4-5 times of ordinary oil country lathe.All of 3 types of oil country lathe can meet the precision requirement of API 5B standard.

Hydrostatic testing machine

The tubing hydrostatic testing machine adopts advanced radial sealing method, which requires end face sealing without thread connection, and adopts a wedge bearing device.The human-machine interface and the computer real-time monitoring system can display the pressure curve and value in real time, and cumulatively record and save each parameter.

Drill Pipe Production Line

API 5DP drill pipe production line is composed by induction heating furnace, automatic feeding and discharging device, hydraulic upsetting press, drift mandrel testing machine, drill pipe heat treatment line, hydraulic straightening machine, oil country lathe, friction welding machine, welding area heat treatment line, painting machine, length & and weight measuring machine and color coding & marking machine, etc.

Hydraulic drill pipe upsetting machine

The rigidity of the main machine is increased, the upsetting force of 400T, and the cavity of 256mm make its working range far beyond that of other models; due to the use of a bilateral locking mechanism, it balances the tilting force of the placenta and makes its work more stable

Hydraulic friction welding machine

The hydraulic friction welding machine can realize automatic tube body feeding, friction welding, inside and outside welding bead removing, drill pipe discharge after welding. The inner welding bead removal is realized by internal punch, outer welding bead removal is done by cutting tool. The equipment actions are consistent, accurate, and the welding part of workpiece is welded at full contact surface, axial and radial orientation is accurate.

Welding area heat treatment line

Intermediate frequency induction furnace is used to heat the welding area of drill pipe to annealing temperature to remove welding stress. After that, welding area is heated to quenching temperature, then water is sprayed to welding area for cooling. At last, welding area is heated to tempering temperature and kept in this temperature for some time.The induction coils have functions of position adjustment(up and down, left and right, front and back) to ensure accurate heating position.During the heating process, drill pipe is rotated on the pipe conveyor to ensure uniform temperature.

Pipe Threading Lathe

CNC pipe thread lathe is a new type of CNC machine tool specially designed and manufactured for the thread processing requirements of oil pipelines, drill pipes and casings in petroleum, chemical and metallurgical industries. The machine tool adopts double chuck clamping workpiece, three-speed inverter and CNC system automatic control. It can accurately process various internal and external threads and has the function of ordinary CNC lathe.

WELDED PIPE PRODUCTION LINE

ERW/HFW Pipe Production Line

The company has four internationally advanced HFW and ERW welded pipe production lines, including Φ60, Φ168, Φ273, Φ660, etc., which can produce ERW steel pipes with an outer diameter of 21.3-660mm, wall thickness of 1-20mm, length of 6-18m, material S235, S355, Q345A, B , C, D, L245-L450, B-X70, with an annual production capacity of 300,000 tons. HFW/ERW products are mainly used in petroleum, natural gas, water, steam, urban gas transmission, urban pipeline network, chemical industry, electric power, steel structure and other industries.

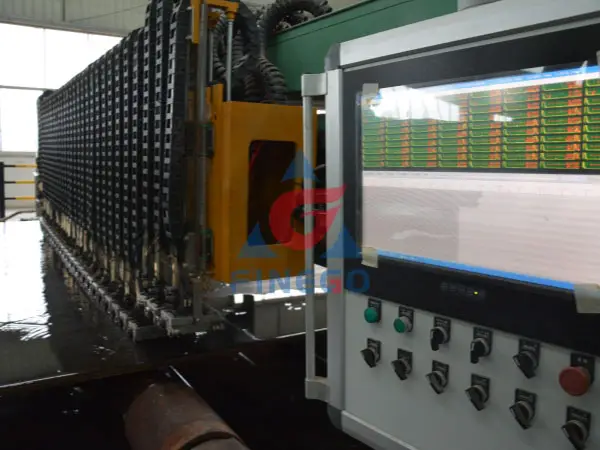

Other Complete Set Of On-line Inspecting and Marking Equipment

The on-line plate ultrasonic tester, weld seam ultrasonic tester, off-line and pipe end ultrasonic tester, hydrostatic tester. And marking recording system from German GABRIEL Company. All these vital equipment guarantees welded pipes of high quality are manufactured.

LSAW/SAWL Pipe Production Line

The factory has introduced a complete set of JCOE and HME production lines for straight seam double-sided submerged arc welded steel pipes, specializing in the production of thick-walled and large-diameter straight seam double-sided submerged arc welded steel pipes and T-shaped welded pipes. The product specifications are OD324mm-OD7000mm, wall thickness 6mm-200mm, length 3m-70m, with an annual production capacity of 500,000 tons.

The product implementation standards are:

ASTM A53, API 5L PSL1/PSL2, ASTM A252, ASTM A671, ASTM A672, ASTM A691, EN10210, EN10217, EN10219, etc. Material: Q235, Q345, Ll75-L555, X42-X80, S235, S275, S355J2, P355NH , P460NH, etc. LSAW products are widely used in various types of oil and gas transmission pipelines and building steel structures, including oil pipelines, natural gas, urban pipeline networks, mine water and coal pipelines, mine coal slurry pipelines, high-voltage transmission lines, wind power, bridges, high-speed railway steel structure buildings, etc.

JOCE Molding Process Production Line

Adopts continuous axis contorting J-C-O(J-ing, C-ing and O-ing)process with characteristics of high forming accuracy and efficiency as well as balanced distribution of forming stress.Which can produce straight seam welded pipe with OD: Φ356~Φ1626mm,WT:6~50mm. The main equipment such as pre-bending is provided by Tianshui forging and pressing machine. The pre-welding adopts high-power CO2 gas shielded welding and high-speed full-length pre-welding process. It adopts Lincoln multi-wire DC/AC automatic submerged arc welding machine, and is equipped with steel plate automatic flame cutting machine, steel pipe straightening machine, steel pipe finishing machine, and steel plate online manual UT flaw detection. It is mainly used for transportation pipes for petroleum, chemical, natural gas, electric power, city gas, water supply and drainage, etc. It is also widely used in construction, bridges, wharfs and other engineering fields.

HME Roll Forming Production Line

The production line is formed by "CCO" using the mandrel rolling method, and is formed by the cold expansion process after welding, and is formed by a three-roll/four-roll bending machine. It can produce straight seam welded pipes with an outer diameter of Φ324mm-Φ7000mm , wall thickness of 8mm-200mm, and a length of 3m-7m. Pre-heat treatment, and then use single wire and multi-wire for inner direct welding, outer direct welding, inner girth welding, and outer girth welding. The feature of this production line is that the product has a large wall thickness and large diameter, which can be widely used in structural pipes, such as steel structure bridges, offshore platform equipment, super-long pipe piles, etc.

SSAW/SAWH Pipe Production Line

Company now has 8 spiral steel pipe production lines and 2 anti-corrosion and heat preservation production lines. It can produce various specifications of spiral steel pipes with a diameter of 219-3500mm, a wall thickness of 4-25.4mm and a length of 3-70m. The product implementation standards are: ASTM A53, API SL PSL1/PSL2, ASTM A252, EN10210, EN10217, EN10219, etc., with an annual production capacity of 600,000 tons, SSAW products are widely used in natural gas, petroleum, chemical, electric power, heat, water, Marine dredging, port construction, infrastructure, urban pipeline network and other fields.

STAINLESS STEEL PIPE PRODUCTION LINE

Stainless Seamless Steel Pipe Production Line

The company has production equipment: 32 cold drawing machines, 9 LG60 cold rolling mills, 2 LG120 cold rolling mills, and 1 LG280 cold rolling mill. The inspection equipment includes chemical composition analyzer, universal chemical testing machine, eddy current flaw detector, ultrasonic flaw detector, hydraulic testing machine, spectrometer imported from Germany and other testing equipment. The production specifications are: outer diameter Φ6~Φ762mm, wall thickness 0.5~50mm; main The grades are: 304L/H, 316L/H, 321L/H, 317L, 310S, 201B, 201H, 2205, S31803, S32750, TP309, TP347/347H, 904L, etc.; GOST, JIS, etc., are widely used in petrochemical, fertilizer, nuclear power, boiler, ship, environmental protection, aviation, paper, food and medical fields. The company is dominated by TP304, 304, TP304L, TP316, TP316L, TP321, 321 stainless steel seamless pipes, especially 310S, 220S, S318003, S32205, S3275, S32760 high temperature resistant steel pipes.

Stainless Welded Steel Pipe Production Line

The introduction of international advanced new stainless steel welded pipe production line, Φ630 automatic continuous production line unit and multiple sets of single-sided welding and double-sided forming German plasma welding and submerged arc welding units, the production of welded pipes can be divided into single straight seam, double straight seam and ring Seam butt joint: single seam (φ6mm-φ1422mm), wall thickness from 0.2mm to 40mm; double seam (φ630-φ2020) wall thickness from 2mm to 80mm, annular seam (above Φ630), wall thickness from 2mm to 100mm. At present, the main materials used by the company are: nickel-based stainless steel (NO8904, N06600, N08825, etc.), duplex stainless steel (S32750, S31803, S32205), austenitic stainless steel (310S, 309S, 316L, 321, 304L, 304, etc.), iron Element body (430, 409L, etc.), copper-nickel alloy (C70600, C70620) and some special steel grades (254SMO, S30815, 253MA)

Single Forming Process Production Line

It has the internationally advanced JCO large-diameter single forming production line, 3200-ton CNC bending forming unit, and rolling unit. It has stainless steel bright, solution heat treatment equipment, online solid solution of pipes, eddy current flaw detection and ultrasonic cleaning equipment, and has perfect inspection and testing. The equipment covers various physical, chemical and non-destructive testing items from raw materials, production processes and finished products. Production and inspection are carried out in strict accordance with ASTM American Standard, JIS Japanese Standard, DIN German Standard and industry standards. The company's products have complete specifications, advanced technology and high quality. The production of pipes covers 304, 304L, 316L, 321, 347, 310S, dual-phase steel, nickel-based alloy steel and other stainless steel materials. Stainless steel pipes of different grades with wall thickness from 0.2mm to 40mm.

Continuous Molding Process Production Line

There are more than 20 continuous molding production lines with complete product specifications, which can produce outer diameters from 6mm to 406mm, wall thicknesses from 0.4mm to 20mm, and an annual design capacity of more than 40,000 tons.

-

HFW Pipe Production Line 1

-

HFW Pipe Production Line 2

-

HFW Pipe Production Line 3

-

HFW Pipe Production Line 4

-

HFW Pipe Production Line 5

-

HFW Pipe Production Line 6

-

HFW Pipe Production Line 7

-

HFW Pipe Production Line 8

-

HFW Pipe Production Line 9

-

HFW Pipe Production Line 10

-

HME Pipe Production Line 1

-

HME Pipe Production Line 2

-

HME Pipe Production Line 3

-

JOCE Molding Process Production Line 1

-

JOCE Molding Process Production Line 2

-

JOCE Molding Process Production Line 3

-

JOCE Molding Process Production Line 4

-

JOCE Molding Process Production Line 5

-

LSAW SAWL Pipe Production Line 1

-

LSAW SAWL Pipe Production Line 2

-

LSAW SAWL Pipe Production Line 3

-

LSAW SAWL Pipe Production Line 4

-

LSAW SAWL Pipe Production Line 5

-

SSAW Pipe Production Line 1

-

SSAW Pipe Production Line 2

-

SSAW Pipe Production Line 3

-

SSAW Pipe Production Line 4

-

SSAW Pipe Production Line 5

-

SSAW Pipe Production Line 6

-

SSAW Pipe Production Line 7

-

Stainless Steel Welded Pipe Process 1

-

Stainless Steel Welded Pipe Process 2

-

Stainless Steel Welded Pipe Process 3

-

Stainless Steel Seamless Pipe Production Line 1

-

Stainless Steel Seamless Pipe Production Line 2

-

Stainless Steel Seamless Pipe Production Line 3

-

Stainless Steel Seamless Pipe Production Line 4

-

Cold Drawn Production Line 1

-

Cold Drawn Production Line 2

-

Cold Drawn Production Line 3

-

Cold Drawn Production Line 4

-

Cold Rolled Production Line 1

-

Cold Rolled Production Line 2

-

Cold Rolled Production Line 3

-

Cold Rolled Production Line 4

-

Hot Rolled Production Line 1

-

Hot Rolled Production Line 2

-

Hot Rolled Production Line 3

-

Hot Rolled Production Line 4

-

Casing&Tubing Production Line 1

-

Casing&Tubing Production Line 2

-

Casing&Tubing Production Line 3

-

Casing&Tubing Production Line 4

-

Casing&Tubing Production Line 5

-

Dirll Pipe Production Line 1

-

Dirll Pipe Production Line 2

-

Dirll Pipe Production Line 3

-

Dirll Pipe Production Line 4

-

Dirll Pipe Production Line 5

Language

Language