- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What is a seamless carbon steel pipe and how do you choose the right grade?

The pressure to source the right materials for an EPC project is high, and making a mistake leads to safety risks and budget overruns. I will help you understand the essentials of seamless piping to make your procurement process easier. A seamless carbon steel pipe is a heavy-duty tube manufactured from a solid steel billet without any longitudinal weld seams. This unique structure provides uniform strength and superior ability to withstand high pressure and temperature compared to welded pipes. It is the standard choice for critical applications in oil, gas, and power generation.

You might assume that all steel pipes are roughly the same, but the way they are made changes everything about their performance. I want to show you exactly why this specific type of pipe matters for your high-stakes projects.

How is a seamless carbon steel pipe actually manufactured?

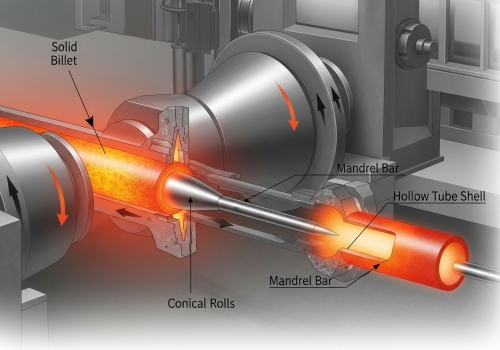

Your finance team often questions why seamless pipes cost more than welded ones. You need to understand the complex production process to explain why this investment prevents expensive failures later. Manufacturers produce this pipe by heating a solid cylindrical steel billet and pushing it over a piercing rod while rolling it. This process creates a continuous hollow shell without a seam, which eliminates the weak points found in welded pipes and ensures the wall strength is the same everywhere.

I find that many people in our industry do not fully grasp the "magic" behind this process. It usually starts with the Mannesmann plug mill process or a similar rotary piercing method. We take a solid bar of steel and heat it until it is glowing red hot. Then, powerful rollers spin the billet and drive it forward over a stationary piercing point. It is violent and requires immense energy. Unlike welded pipes (ERW or LSAW), which start as a flat plate that is curled and fused, a seamless carbon steel pipe is born from a solid piece. This is crucial for you to understand. In a welded pipe, the Heat Affected Zone (HAZ) near the seam can sometimes change the metallurgical properties of the steel. It creates a potential line of weakness. Seamless pipes do not have this issue. After the initial piercing, the pipe goes through other steps to fix the outer diameter and wall thickness. This can happen while the steel is hot (Hot Finished) or after it cools down (Cold Drawn). If you need very tight tolerances for a precision machine part, I always recommend Cold Drawn. But for general high-pressure lines in a refinery, Hot Finished is usually the standard choice. This uniform structure is why Finego Steel has been able to supply major oil companies for decades without quality complaints.

Which seamless carbon steel pipe grades should you look for?

Navigating the alphabet soup of ASTM, API, and ASME standards is confusing and often leads to ordering errors. I see many purchasing managers waste time returning materials because the grade did not match the engineering spec. The most common grades include ASTM A106 for high-temperature service, ASTM A53 for general fluid and air transport, and API 5L for the oil and gas industry. Your choice must depend strictly on the temperature, pressure, and the chemical nature of the fluid you are transporting.

I have spent years working with these specifications, and I can tell you that mixing them up is a common mistake. You need to look at the "Scope" of each standard. I have created a breakdown below to help you see the differences clearly.

| Grade Specification | Primary Application | Temperature Limitations | Key Characteristic |

|---|---|---|---|

| ASTM A106 | Power plants, Refineries, Boilers | Up to 750°F (approx 400°C) | Designed specifically for high temperatures and high pressures. |

| ASTM A53 | Low pressure water, air, steam | Up to 550°F (approx 288°C) | The "general purpose" pipe. Can be seamless or welded. |

| API 5L | Oil and gas transmission lines | Varies by PSL level | High strength, often tested for sour service (H2S environments). |

| ASTM A333 | Cryogenic / Cold service | -50°F to +600°F | Impact tested to ensure it does not shatter in freezing conditions. |

When you buy an A106 pipe, you are paying for the assurance that it can handle heat. A Grade B pipe is the industry workhorse. It has a good balance of tensile strength and weldability. If you need higher strength, you might look at Grade C, but it is harder to weld.

On the other hand, API 5L is what we supply to clients like CNPC and Shell. This standard focuses on toughness and the ability to travel long distances underground or underwater. It has strict requirements for chemical composition to prevent cracking. At Finego Steel, we ensure our inventory covers all these grades because we know a single project often needs a mix of A106 for the plant and API 5L for the pipelines feeding it.

Why do critical industries prefer seamless carbon steel pipe over welded options?

A pipe failure in a chemical plant or power station can cause explosions, environmental disasters, and loss of life. You cannot afford to risk safety just to save a small percentage on the initial material cost. Seamless pipes offer significantly higher pressure ratings and better resistance to mechanical stress because they lack a longitudinal weld seam. This makes them the safest option for high-risk environments like thermal power generation, petrochemical processing, and high-pressure hydraulic systems where reliability is non-negotiable.

Let's dig deeper into the physics here. When you pressurize a pipe, the force pushes out against the walls. This is called hoop stress. In a welded pipe, that stress is pulling directly against the weld seam. Even with X-ray testing, the weld is statistically the most likely place for a failure to start. A seamless carbon steel pipe distributes this load evenly around the entire circumference. There is also the issue of corrosion. Corrosion loves irregularities. The seam area in a welded pipe can sometimes corrode faster than the rest of the pipe due to slight differences in the metal structure caused by the welding heat. Seamless pipes corrode evenly, which makes predicting their lifespan much easier for your maintenance engineers. I also see a huge advantage in installation. Seamless pipes are generally easier to thread and groove because you don't have to worry about the tool hitting a hard weld bead. This saves time on the job site. For industries like automotive or construction, where we supply pipes for chassis or scaffolding, the high tensile strength of seamless carbon steel provides a safety factor that welded pipes struggle to match. At Finego Steel, we focus on these high-end applications because we believe in "Safety First."

How can you find a reliable supplier for seamless carbon steel pipe?

Global supply chains are unstable, and a late delivery of piping can stall your entire construction schedule. You need a partner who understands logistics and quality control, not just a trader who disappears after the sale. A reliable supplier must provide integrated services, including verified ISO certifications, third-party inspections like SGS or TUV, and complete mill test certificates. You should look for companies like Finego Steel that have large inventories and experience with global EPC contractors to ensure your timeline is met.

I have learned that the paper trail is just as important as the steel itself. When you source piping, you must demand a Mill Test Certificate (MTC) according to EN 10204 3.1 or 3.2. This document proves the chemical analysis and mechanical testing of the batch you bought. If a supplier hesitates to give you this, run away. At Finego Steel, we act as an integrated supporting supplier. This means we don't just sell you a pipe. We can coat it with 3LPE or FBE for corrosion protection. We can cut it to length. We can bundle it with the matching fittings and valves. This "One-Stop" approach saves you from chasing five different vendors. You should also ask about their client list. We have served companies like ExxonMobil and Petrobras. This matters because these companies have the strictest audits in the world. If a supplier has passed those audits, you know their quality management system (ISO 9001) is real. We treat every order, whether it is for a local construction project or a massive cross-border pipeline, with the same level of rigor. We inspect the wall thickness, the diameter, and the surface finish before anything leaves our base.

Conclusion

Choosing the right seamless carbon steel pipe requires matching the grade to your environment and selecting a supplier with proven quality control. When you prioritize technical accuracy and supply chain reliability, you ensure your project runs safely and on budget.

- Prev : Centerway Steel Holds 2025 Annual Review Meeting to Strengthen Teamwork and Drive Global Steel Export Growth

- Next : No matching information found

Language

Language