- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

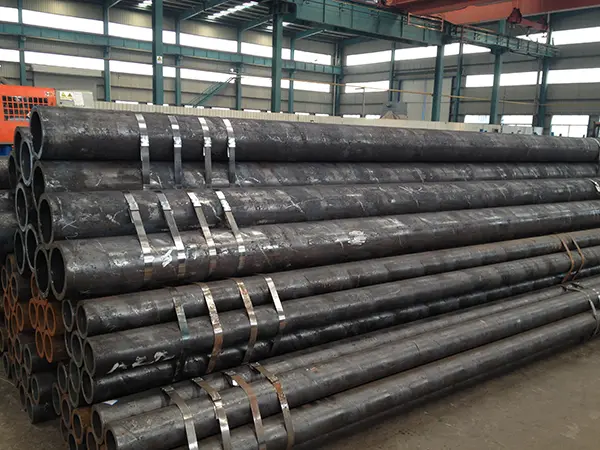

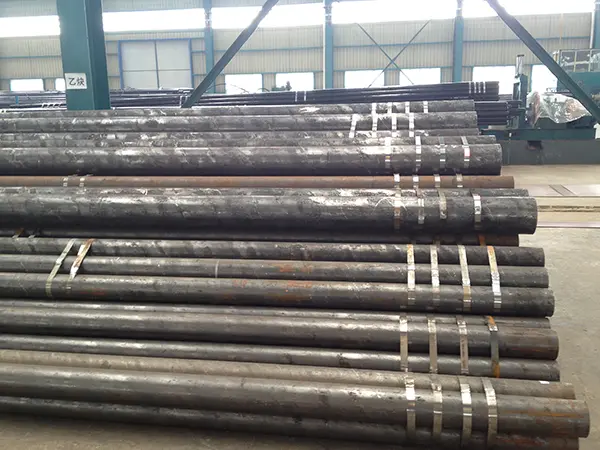

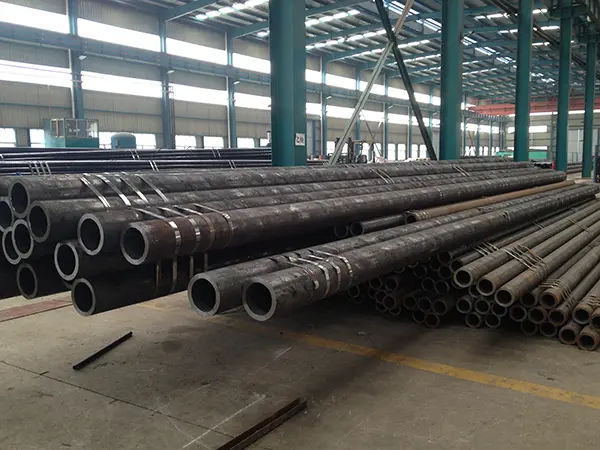

Seamless Steel Pipe

Carbon Seamless Steel Pipe

Type: hot rolled seamless steel pipe (hrs), cold rolled seamless steel pipe (crs), cold drawn seamless steel pipe (cds), general seamless carbon steel pipe.

Application: mainly for the manufacture of water wall pipes, boiling water pipes, superheated steam pipes, superheated steam pipes for locomotive boilers, large and small smoke pipes and arched brick pipes.

Outside Diameter: 1/4" (8mm)-80" (2000mm)

Thickness: 2.11mm-60mm

Length: 3m-12m

Surface: 3pe coating,3pp coating,fbe coating,epoxy coating,special painting

Standard: API 5l, API 5CT, ASTM A53, ASTM A106, ASTM A179, ASTM A192, ASTM A252, ASTM A333, ASTM A335, ASTM A672

Technique: cold rolled/hot rolled/cold drwan.

Standard

- API Spec 5L

- ASTM A106/A106M

- ASTM A178/A178M

- ASTM A179/A179M

- ASTM A192/A192M

- ASTM A209/A209M

- ASTM A210/A210M

- ASME SA53/SA53M

- ASME SA106/SA106M

- ASME SA178/SA178M

- ASME SA179/SA179M

- ASME SA192/SA192M

- ASME SA209/SA209M

- ASME SA210/SA210M

- BS 1387

- BS 3059

- DIN 1629

- EN 10204

- EN 10210

- EN 10216-2

- EN 10217

- EN 10219

- EN 10296

- EN 10297

- EN 10312

- JIS G3441

- JIS G3444

- JIS G3445

- JIS G3452

- JIS G3454

- JIS G3456

- JIS G3457

- JIS G3461

- JIS G3462

Specification

Carbon steel seamless pipe is stronger and long lasting thanseamless steel pipe because of its higher carbon content. Additionally, since it has a higher tensile strength, it can handle more pressure without becoming too brittle or weak.

It has superior durability and strength compared to welded pipes, making it suitable for various engineering applications, such as those related to the transportation of fluids and high-temperature services. Theseamless carbon steelpipes are available in different sizes and can be customized according to the customer’s needs. This type of pipe makes a great choice for many manufacturing processes due to its corrosion resistance, chemical stability, better formability, low cost, and ease of fabrication.

Carbon steel seamless pipes are commonly used in construction, oil and gas, and other heavy-duty industrial applications. They are ideal for transporting liquids and gases at high temperatures and pressures.

Uses:

|

Chilled water pipe |

Steam/condensate pipe |

Heat exchanger pipe |

Marine/offshore pipe |

Dredging pipe |

Industrial pipe |

|

Oil and gas pipe |

Fire fighting pipe |

Construction/structure pipe |

Irrigation pipe |

Drain/sewage pipe |

Boiler tube |

Coating:

|

3PE Coating |

3PP Coating |

FBE Coating |

Epoxy Coating |

Special Painting |

Standard of carbon seamless steel pipe:

|

ASTM A53 Gr.B |

Black and hot-dipped zinc-coated steel pipes welded and seamless |

|

ASTM A106 Gr.B |

Seamless carbon steel for high temperature service |

|

ASTM SA179 |

Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

|

ASTM SA192 |

Seamless carbon steel boiler tubes for high pressure |

|

ASTM SA210 |

Seamless Medium-carbon boiler and superheater tubes |

|

ASTM A213 |

Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

|

ASTM A333 GR.6 |

seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

|

ASTM A335 P9,P11,T22,T91 |

Seamless ferritic alloy-steel pipe for high-temperature service |

|

ASTM A336 |

Alloy steel forgings for pressure and high-temperature parts |

|

ASTM SA519 4140/4130 |

Seamless carbon for mechanical tubing |

|

API Spec 5CT J55/K55/N80/L80/P110/K55 |

Seamless steel pipe for casing |

|

API Spec 5L PSL1/PSL2 Gr.b, X42/46/52/56/65/70 |

Seamless steel pipe for line pipe |

|

DIN 17175 |

Seamless steel tube for elevated temperture |

|

DN2391 |

Cold drawn seamless prevision pipe |

|

DIN 1629 |

Seamless circular unalloyed steel tubes subject to special requirements |

Chemical components & mechanical properties:

|

Standard |

Grade |

Chemical Components (%) |

Mechanical Properties |

||||||

|

ASTM A53 |

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

|

|

|

A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

|

|

|

B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

|

|

|

ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

|

|

|

ASTM SA179 |

A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

|

ASTM SA192 |

A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

≥331 |

≥207 |

|

|

B |

0.28 |

- |

1.20 |

0.030 |

0.030 |

≥414 |

≥241 |

|

|

|

X42 |

0.28 |

- |

1.30 |

0.030 |

0.030 |

≥414 |

≥290 |

|

|

|

X46 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥434 |

≥317 |

|

|

|

X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥455 |

≥359 |

|

|

|

X56 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥490 |

≥386 |

|

|

|

X60 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥517 |

≥448 |

|

|

|

X65 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥531 |

≥448 |

|

|

|

X70 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥565 |

≥483 |

|

|

|

API 5L PSL2 |

B |

0.24 |

- |

1.20 |

0.025 |

0.015 |

≥414 |

≥241 |

|

|

X42 |

0.24 |

- |

1.30 |

0.025 |

0.015 |

≥414 |

≥290 |

|

|

|

X46 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥434 |

≥317 |

|

|

|

X52 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥455 |

≥359 |

|

|

|

X56 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥490 |

≥386 |

|

|

|

X60 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥517 |

≥414 |

|

|

|

X65 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥531 |

≥448 |

|

|

|

X70 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥565 |

≥483 |

|

|

|

X80 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥621 |

≥552 |

|

|

Classfication of carbon seamless steel pipe:

|

Types |

Application |

|

Structure Purposes |

General structure and mechanical |

|

Liquid Services |

Petroleum, gas and other fluids conveying |

|

Low and Medium Pressure Boiler Tube |

Steam and boiler manufacturing |

|

Hydraulic Pillar Service |

Hydraulic support |

|

Auto Semi-shaft Casing |

Auto sem-shaft casing |

|

Line Pipe |

Oil and gas conveying |

|

Tubing and Casing |

Oil and gas conveying |

|

Drill Pipes |

Well drilling |

|

Geological Drilling Pipe |

Geological drilling |

|

Furnace tubes, heat exchangers tubes |

Furnace tubes, heat exchangers |

Tolerances of carbon seamless steel pipe:

|

Pipe types |

Pipe sizes(mm) |

Tolerances |

|

Hot rolled |

OD<50 |

±0.50mm |

|

OD≥50 |

±1% |

|

|

WT<4 |

±12.5% |

|

|

WT 4~20 |

+15%, -12.5% |

|

|

WT>20 |

±12.5% |

|

|

Cold drawn |

OD 6~10 |

±0.20mm |

|

OD 10~30 |

±0.40mm |

|

|

OD 30~50 |

±0.45 |

|

|

OD>50 |

±1% |

|

|

WT≤1 |

±0.15mm |

|

|

WT 1~3 |

+15%, -10% |

|

|

WT >3 |

+12.5%, -10% |

Process

The process begins with solid steel rounds, or billets, being cut to a specified length and sent through a walking-beam reheat furnace, where temperatures reach nearly 2,300°f. After exiting the reheat furnace, the preheated rounds are turned into a tube shell in the rotary piercing mill as the billets are cross-rolled between two barrel-shaped rolls at a high speed. The seamless shells enter mandrel mill, where they are rolled over a retained mandrel to provide the needed od size and wall thickness for the next process. The process is carefully monitored using a state-of-the-art hot-wall measuring system. The shells are then reheated for final forming in a 24-stand stretch-reducing mill, where outside diameters are formed to customers’ exacting specifications. Wall thickness is again verified using a hot-wall measuring system. After being rotated and advanced on the walking-beam cooling bed, the pipes are batch cut and transferred to an in-process storage area, where they are handled by computer-controlled gantry cranes.

Language

Language