- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

How does the lsaw steel pipe manufacturing process guarantee quality for your project?

High-pressure projects leave no room for error or weak materials. Using the wrong pipe can lead to catastrophic leaks and massive financial losses for your company. The lsaw steel pipe manufacturing process involves cold-forming heavy steel plates into cylinders using JCOE or UOE methods. We weld these seams with double-sided submerged arc technology, then expand the diameter to ensure high precision, making them ideal for oil, gas, and heavy construction.

I have worked in this industry for many years. I know that understanding the technical side helps you buy better products. Let us look at how we make these pipes.

What is the difference between UOE and JCOE forming methods?

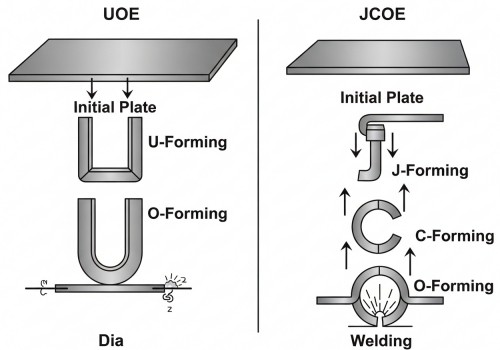

Many buyers get confused by the different acronyms in production specs. This confusion can lead to ordering pipes that do not fit your specific delivery timeline or budget. UOE and JCOE are the two main forming methods in the lsaw steel pipe manufacturing process. UOE is faster and better for large batches, while JCOE is more flexible and suits smaller, custom orders. Both produce high-quality pipes.

At Finego Steel, we want you to know exactly how we shape the steel. The process starts with a flat steel plate. This is different from seamless pipes that start from a round billet. For LSAW pipes, the forming stage is critical. In the UOE method, the machine presses the plate edge first. Then, a massive press pushes the plate into a "U" shape. After that, another press closes it into an "O" shape. This method is very fast. If you have a massive pipeline project with thousands of kilometers, UOE is often the right choice because of the high production rate. The JCOE method is a bit different. It uses a progressive bending process. The machine presses the plate to make a "J" shape first. Then it presses again to make a "C" shape. Finally, it closes into an "O" shape. This takes a little more time than UOE. However, it is excellent for thick walls and difficult specifications. It allows us to control the shape very carefully. Here is a simple comparison to help you decide:

| Feature | UOE Method | JCOE Method |

|---|---|---|

| Production Speed | Very High | Moderate |

| Batch Size | Best for large orders | Good for small to medium orders |

| Flexibility | Lower | Higher |

| Typical Diameter | Fixed sizes usually | Adjustable sizes |

| Cost | Lower for mass production | Lower for custom sizes |

Why is the expansion step critical in the manufacturing process?

Welding generates intense heat that can warp the steel and create internal stress. If we ship pipes like this, they might ovalize or fail to fit together at your construction site. Mechanical expansion, or the "E" in JCOE/UOE, creates the final precise dimensions. A mechanical head expands the pipe from the inside, relieving welding stress and ensuring the pipe is perfectly round for easy installation.

How do we verify quality before shipping to your site?

You cannot see internal cracks or weak points with the naked eye. Relying on visual checks alone puts your entire infrastructure project at risk of failure. We use rigorous testing including hydrostatic pressure tests and ultrasonic detection. These tests confirm that the chemical composition and mechanical strength meet international standards like API 5L and ISO, ensuring safety.

At Finego Steel, we believe that quality is the most important part of our job. We produce pipes for critical missions. Our clients use them for oil and gas transmission, sewage treatment, and offshore structures. A failure is not an option. We start testing raw materials before we even begin forming. We check the chemical components of the steel plate. We need to know it has the right amount of carbon and manganese. This ensures the steel is strong but also weldable. Once the pipe is made, we perform non-destructive testing (NDT). We use X-ray examinations to look inside the weld seam. This shows us if there are any air bubbles or cracks hidden inside. We also use ultrasonic testing. This is like a sonar for steel. It finds imperfections that X-rays might miss. The most important test for pressure pipes is the Hydrostatic Test. We fill the pipe with water and pressurize it. We hold this pressure for a specific time. This simulates the real conditions in your pipeline. If the pipe does not leak or deform, it passes. We also do physical tests on sample pieces. We do a flattening test and a bending test. We also check impact toughness. This is important for cold environments. If you use pipes in a freezing place, the steel must not become brittle. Our strict process ensures that every pipe leaving our factory is ready for the toughest jobs. Whether for piling in a port or carrying high-pressure gas, our LSAW pipes deliver the performance you need.

Conclusion

The lsaw steel pipe manufacturing process combines advanced forming, precise welding, and strict testing. At Finego Steel, we ensure every pipe meets your high standards for safety and durability.

- Prev : What Are the Essential Specifications of API 5L Pipes for Your Project?

- Next : No matching information found

Language

Language