- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What makes ASTM A53 steel pipe the ideal solution for pressure and structural needs?

You need pipes that handle pressure and look good structurally, but finding the right spec is confusing. It causes delays and budget issues. Let me simplify this for you. ASTM A53 steel pipe is a carbon steel alloy designed for low-pressure plumbing, structural support, and air, steam, water, or gas lines. It comes in three types (F, E, S) and two grades (A, B), offering excellent weldability and corrosion resistance for industrial EPC projects.

I see many purchasing managers struggle with these specifications. You want to buy the right material without overspending. I will break down everything you need to know about this standard.

What are the specific types and grades of ASTM A53 pipe?

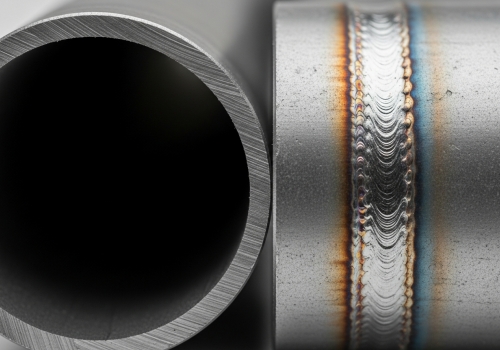

Selecting the wrong pipe grade ruins inspections. You face project rejections and lost money. Avoid this by understanding the specific classifications first. ASTM A53 features three types: Type F (Furnace-butt welded), Type E (Electric-resistance welded), and Type S (Seamless). It also splits into Grade A for bending and Grade B for higher pressure, giving you flexibility for specific engineering requirements.

I have worked in this industry since 1996, and I see people confuse these types all the time. To save costs for your company, you must know the difference. The standard covers both seamless and welded black and hot-dipped galvanized steel pipe. Let's look at the three types closely. Type F is furnace-butt welded. It relies on Grade A steel. It is continuous welded and good for basic use, but I do not recommend it for flanging. Type E is Electric-Resistance Welded (ERW). It comes in Grade A and Grade B. This is very common in construction. Type S is seamless. This is for when you need the highest integrity. Then you have the Grades. Grade A has lower carbon. It is softer. If your engineers need to bend the pipe for coils, use Grade A. Grade B is what I sell the most. It has higher carbon and higher tensile strength. It is harder but stronger. Here is a breakdown of the chemical limits. You can see why Grade B is stronger.

| Element | Grade A (Max %) | Grade B (Max %) |

|---|---|---|

| Carbon | 0.25 | 0.30 |

| Manganese | 0.95 | 1.20 |

| Phosphorus | 0.05 | 0.05 |

| Sulfur | 0.045 | 0.045 |

How does ASTM A53 ensure safety in high-pressure environments?

Leaks and bursts are a nightmare for any site manager. They endanger lives and stop work. You must know how your materials are tested before installation. A53 pipes undergo rigorous hydrostatic testing to verify they handle internal pressures. Manufacturers use the Barlow Equation to set test limits, ensuring the pipe exceeds service pressure requirements. This guarantees safety for gas, steam, and water transport systems.

Safety is the top priority for my clients in Germany and globally. When we supply pipes, we know they must hold up. The testing process for astm a53 steel pipe is very strict. The mill applies hydrostatic pressure to the pipe. This pressure must be higher than the actual pressure the pipe will face in real life. This provides a safety margin. Inspectors use a math formula called the Barlow Equation. It looks like this: P = (2 * t * S) / D.

· P is pressure.

· t is wall thickness.

· S is allowable stress.

· D is the outside diameter. This formula helps us find the bursting pressure. For example, a standard Grade B pipe usually has a minimum yield strength of 35,000 psi. If the pressure goes too high, the pipe will burst. Our tests ensure that does not happen under normal loads. Besides pressure, we look at mechanical strength. This determines how much the pipe can stretch or carry before it breaks. Grade B is the industry favorite because it is tough.

| Property | Grade A | Grade B |

|---|---|---|

| Tensile Strength (min) | 48,000 psi (330 MPa) | 60,000 psi (415 MPa) |

| Yield Strength (min) | 30,000 psi (205 MPa) | 35,000 psi (240 MPa) |

I always tell my customers: if you have a high-pressure application, stick to Grade B. It handles the stress better.

Why should you choose A53 over A500 or A106?

Mixing up standards like A500 or A106 happens often. It leads to compliance failures. You must know exactly when to swap them and when to stick to A53. While A500 is strictly for structure and A106 is for high temperatures, astm a53 steel pipe bridges the gap. It handles pressure better than A500 and is more cost-effective than A106 for medium-temperature applications, making it a versatile dual-purpose choice.

I often get asked to substitute one pipe for another. You need to be careful here. Let's compare A53 with A500 first. A500 is structural tubing. It is great for columns and frames in buildings. However, A500 is rarely pressure tested. If you use A500 to carry gas or water, you are taking a risk. A53 is dual-certified. It works for structure and pressure. If you are buying for a project that needs both, A53 simplifies your inventory. Now, consider ASTM A106. This is a seamless pipe for high-temperature service. It is very similar to A53 Type S Grade B. In fact, many mills produce pipe that meets both standards. We call this "dual certified" pipe. But, A106 generally costs more. If your temperature stays below 750 degrees F, you do not need to pay extra for A106. A53 is the cost-effective choice. Also, think about the finish. A53 often comes galvanized (coated in zinc). A500 and A106 are usually black. If you need corrosion resistance without painting it yourself, A53 is the winner. Here is a quick guide I use to help customers decide:

| Feature | ASTM A53 | ASTM A500 | ASTM A106 |

|---|---|---|---|

| Primary Use | Pressure & Structure | Structure Only | High-Temp Pressure |

| Galvanized? | Yes, Common | Rare | No |

| Cost | Moderate | Low | High |

| Seamless? | Yes (Type S) | No | Yes |

What are the key applications and coating options for this material?

Rust destroys pipelines and increases maintenance costs. Your client will blame you for early corrosion. You must select the right coating for the final environment. You can order A53 pipes black (uncoated) or hot-dipped galvanized. The zinc coating creates a sacrificial layer against corrosion. This makes them perfect for outdoor structural columns, refinery piping, and municipal water lines where elements attack the steel.

I have supplied pipes to over 100 countries, from humid Southeast Asia to the dry Middle East. The environment matters. ASTM A53 is fantastic because it adapts to these places. The "black" version is just raw steel. It usually has a simple lacquer to stop rust during shipping. We use this for oil and steam lines where the outside appearance does not matter, or where you will insulate the pipe anyway. It is also good for welding because you do not have to grind off a thick coating. The "galvanized" version is dipped in molten zinc. This is vital for water lines or outdoor handrails. The zinc fights the rust so the steel does not have to. Even if the pipe gets scratched, the zinc protects it. This extends the life of the project significantly. Applications are vast. In the energy sector, we ship A53 for refinery piping and gas lines. In construction, it is used for pilings, scaffolding, and fencing. Because it has high shock resistance, it is even used in seismic zones. The metal absorbs vibration better than brittle materials. At Finego Steel, we integrate these products. We offer one-stop sourcing. Whether you need the pipe coated, cut to length, or threaded, we handle it. This saves you from dealing with three different vendors. We hold ISO 9001 and ISO 14001 certs, so you know the quality is real.

Conclusion

ASTM A53 steel pipe is the versatile, safe choice for pressure and structure. It saves costs and resists corrosion. For reliable, tested pipes, Finego Steel is your partner.

Language

Language