- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

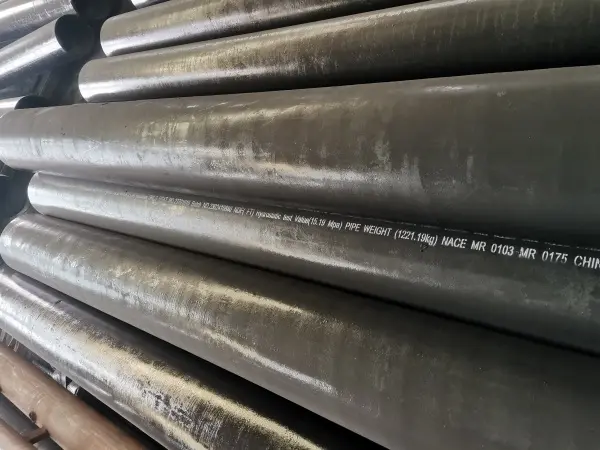

Seamless Steel Pipe

ASTM A53 Steel Pipe

Product Dimension: SMLS:φ10.3-720×1.7-52mm

Uses: For conveying gas,water and oil either in the oil or natural gas industries

Product Specification Level: Psl1, psl2, onshore and offshore sour services

Thickness Schedule: Sch 10. sch 20, sch 40, sch std, sch 80, sch xs, to sch 160

Outer Diameter: 1/4"-36"

Wall Thickness: 1.25mm-50mm

Length: 3-12 meters, Support customization

Surface Process: Bright, Polished, Black

Standard

Specification

ASTM A53 steel pipe (also referred to as ASME SA53 pipe) is a carbon steel alloy, which can be used as structural steel pipes or for low-pressure pipelines and is also acceptable for ordinary uses in steam, water, gas and air lines.the alloy specifications are set by astm international in the specifications ASTM A53 / A53m.

A53 pipe comes in three types (f, e, s) and two grades (a, b).

A53 type f is manufactured with a furnace butt weld or may have a continuous weld (grade a only)

A53 type e has an electric resistance weld (grades a and b)

A53 type s is a seamless pipe and found in grades a and b

A53 grade b seamless pipe is our most polar product under this specification and a53 pipe is commonly dual certified to a106 b seamless pipe.

Pipe ordered under this specification is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas, and air lines. it is suitable for welding, and suitable for forming operations involving coiling, bending, and flanging, subject to the following qualifications:

1. Type f is not intended for flanging.

2. When types s and e are required for close coiling or cold bending, grade a is the preferred grade. this provision is not intended to prohibit the cold bending of grade b pipe.

3. Type e is furnished either nonexpanded or cold expanded at the option of the manufacturer.

Scope:

ASTM A53 pipe covers seamless and welded, black and hot-dipped galvanized nominal (average) wall pipe for coiling, bending, flanging and other special purposes and is suitable for welding. continuous-welded pipe is not intended for flanging. purpose for which pipe is intended should be stated on order.

Chemical properties %:

|

|

grade |

c, max |

mn, max |

p, max |

s, max |

cu*, max |

ni*, max |

cr*, max |

mo*, max |

v*, max |

|

type s(seamless) |

a |

0.25 |

0.95 |

0.05 |

0.05 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

|

b |

0.3 |

1.2 |

0.05 |

0.05 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

|

|

type e (electric-resistance welded) |

a |

0.25 |

0.95 |

0.05 |

0.05 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

|

b |

0.3 |

1.2 |

0.05 |

0.05 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

|

|

type f (furnace-welded) |

a |

0.3 |

1.2 |

0.05 |

0.05 |

0.4 |

0.4 |

0.4 |

0.15 |

0.08 |

note: the total composition for these five elements shall not exceed 1.00%.

Mechanical properties comparison:

|

|

grade a |

grade b |

|

tensile strength, min., psi, (mpa) |

48,000 (330) |

60,000 (415) |

|

yield strength, min., psi, (mpa) |

30,000 (205) |

35,000 (240) |

Note: this is summarized information from asme specification a53. please refer to the specific standard or specification or contact us for more details.

Applications of ASTM A53:

1. Construction: the pipeline underneath, the groundwater, and the hot water transportation.

2. Mechanical processing, bearing sleeves, processing machinery parts, etc.

3. Electrical: gas delivery, hydroelectric power fluid pipeline

4. Anti-static tubes for wind power plants, etc.

Process

Seamless steel pipe manufacturing process is divided into hot-rolled and cold seamless pipe.

1. Production process of hot-rolled seamless steel pipe: tube billet → heating → perforation → three-roller/cross-rolling & continuous rolling → de-pipe → sizing → cooling → straightening → hydraulic test → marking → seamless steel pipe with leverage effect detected.

2. Production process of cold drawn seamless steel tubes: tube blank → heating → perforation → heading → annealing → pickling → oiling → multiple cold drawing → blank tube → heat treatment → straightening → hydraulic test → marking → storage.

Tips: Seamless pipe is often made by drawing a solid shape over a mandrel to form the configuration of a tube. welded pipe is more commonly made by rolling a flat strip of material into a tube and joining the edges together with a longitudinal weld. the weld can be made by either electric resistance welding (type e) or by furnace butt welded/continuous welding (type f).

Language

Language