- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

I-Beam vs H-Beam: Which Structural Steel Solution Is Right for Your Project?

Are you hearing conflicting advice about whether H-beams or I-beams are better for your current tender? It happens often, and while it is frustrating to hunt down trustworthy information, choosing the wrong profile can lead to costly structural failures. I will use my industry experience to clarify these differences for you. The main difference in the i beam vs h beam comparison lies in their shape and load capacity. An H-beam has wider, parallel flanges and supports massive vertical loads, making it perfect for columns. An I-beam has tapered flanges and is lighter, making it ideal for resisting bending in horizontal spans.

Many purchasing managers I talk to think these two beams are interchangeable, but they are not. Mixing them up can cause delays in your EPC projects and rejection from site engineers. Let us stop guessing and start analyzing the real technical details below so you can make the right purchase.

What Are the Physical and Manufacturing Differences Between These Beams?

You might look at a blueprint and see two beams that appear almost identical, which is a common frustration for buyers. If you order the wrong specification, your fabrication team will face serious welding and fitting issues during installation. Physically, an H-beam looks like a square with parallel flanges, while an I-beam is taller than it is wide with tapered flanges. Manufacturing also differs; H-beams are often built-up (welded), allowing for custom sizes, whereas I-beams are typically hot-rolled from a single piece of steel for standard efficiency.

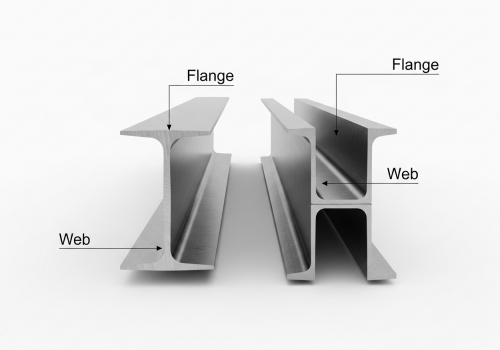

To truly master the i beam vs h beam debate, you must look closely at the cross-section. We call the vertical section the "web" and the horizontal sections the "flanges." In an I-beam, the flanges are short and taper off at the edges. This creates a slope of about 1:6. This design is excellent for certain connections but makes bolting difficult without special tapered washers. Because I-beams are usually milled or rolled from one solid piece of metal, their dimensions are fixed by the mill's capacity. You buy what the mill produces. On the other hand, the H-beam is a beast of a different nature. The flanges are much wider and the surfaces are parallel. There is no taper. This makes welding and bolting much easier for your site teams, which saves time. Furthermore, because we often fabricate H-beams by welding three separate plates together, we can customize the web thickness and flange width to your exact engineering requirements. This flexibility is why we at Centerway Steel often recommend H-beams for complex industrial clusters where standard rolled sizes just do not fit the bill. The web of an H-beam is also much thicker, which brings us to the next critical point about strength.

How Do Load Capabilities and Span Distances Compare?

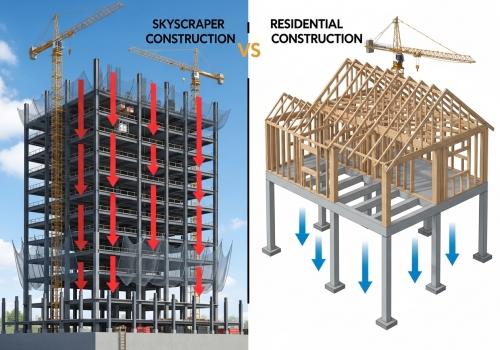

Engineers constantly worry about buckling and torsion when calculating loads for high-rise structures or heavy industrial plants. If you select a beam that is too light, the entire integrity of your building or bridge is at risk. H-beams are the clear winner for heavy loads and columns because their thick webs resist buckling and twisting. I-beams are lighter and work best for shorter spans (33-100 feet) where weight savings are priority. For spans up to 330 feet, you will almost always need the strength of an H-beam.

When we discuss strength, we have to talk about distribution. An I-beam is taller than it is wide. It is designed to take heavy loads on its vertical axis (gravity), but it is weak against twisting forces (torsion). If you use an I-beam as a standalone column, it might buckle if the load shifts or wind hits it from the side. However, because it is lighter, it puts less strain on the rest of the structure when used horizontally as a floor joist. It is cost-effective for spans between 10 to 30 meters. H-beams are heavier, but that weight buys you safety. The wider flanges and thicker web provide a better distribution of steel. This results in a higher "moment of inertia" laterally. In simple terms, an H-beam fights against bending in any direction much better than an I-beam. This makes H-beams the standard for columns in skyscrapers, platforms on oil rigs, and heavy industrial piles. Here is a quick reference table I created to help you visualize the trade-offs:

| Feature | I-Beam (Standard) | H-Beam (Wide Flange) |

|---|---|---|

| Shape | Taller than wide, tapered flanges | Square-like, parallel flanges |

| Web Thickness | Thinner | Thicker |

| Main Use | Horizontal Beams (Bending resistance) | Vertical Columns (Compression/Buckling) |

| Span Capabilities | Short to Medium (33-100 ft) | Long (up to 330 ft) |

| Fabrication Method | Usually Rolled (One piece) | Often Built-up (Welded 3 pieces) |

| Cost Factor | Lower per meter (lighter weight) | Higher per meter (heavier weight) |

Which Beam Should You Choose for Your Specific Application?

Budget constraints often clash with safety requirements, leaving you in a difficult position as a buyer or project manager. You do not want to overpay for steel you do not need, but you cannot compromise on safety for your end-user. Use I-beams for lighter commercial frames, elevator shafts, and truck beds where space and weight are limited. Choose H-beams for bridges, marine platforms, skyscrapers, and massive industrial complexes where the structure must endure extreme pressure. The choice depends on whether you need a beam or a column. In my 18 years working with global partners in the construction industry, I have seen how the i beam vs h beam decision impacts the bottom line. If you are building a mezzanine floor in a warehouse or a frame for a trailer, the I-beam is your friend. It is efficient and eco-friendly because it uses less steel. It is also great for elevator shafts and hoist tracks because the tapered flange fits certain wheel profiles perfectly. Using I-beams here minimizes dead weight on the foundation. However, if your project involves the oil and gas sectors—like many of Centerway Steel's clients such as Aramco or CNPC—you are likely looking at H-beams. We use them for heavy machinery bases, offshore platforms, and main support columns. A bridge, for example, needs to support traffic loads over a long distance. An H-beam distributes this weight evenly. If you try to use I-beams for a 300-foot span, you would need to weld multiple units together or use three times as many beams. This increases labor costs and introduces more failure points. Always match the beam to the force it must resist: I-beams for bending efficiency, H-beams for compression and shear strength.

Conclusion

Understanding the i beam vs h beam difference saves money and ensures safety. I-beams are light and great for horizontal spans; H-beams are heavy and essential for vertical columns.

Language

Language