- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What is a hot dip galvanized steel pipe and why does your project need it?

Rust is the biggest enemy of any steel project, eating away your budget and safety. If you ignore corrosion, you will face expensive repairs and dangerous failures very soon. Hot dip galvanized steel pipe is a carbon steel pipe that has been dipped into molten zinc. This process creates a thick, chemically bonded layer that protects the steel from rust for decades, making it ideal for tough industrial and outdoor environments.

Many people ask me about the best way to protect their pipelines. I always tell them the same thing. You need to understand how this process works. It is not just about painting a pipe. It is about science. Let's look at the details so you do not waste your money on the wrong product.

How is hot dip galvanized steel pipe actually manufactured?

Do you think all coated pipes are the same quality? If you do not understand the manufacturing process, you might buy a product that peels off after just one winter. The manufacturing method involves cleaning the steel perfectly and then submerging it in a bath of liquid zinc at around 450°C. This extreme heat causes a reaction that fuses the zinc to the steel, creating an inseparable alloy bond.

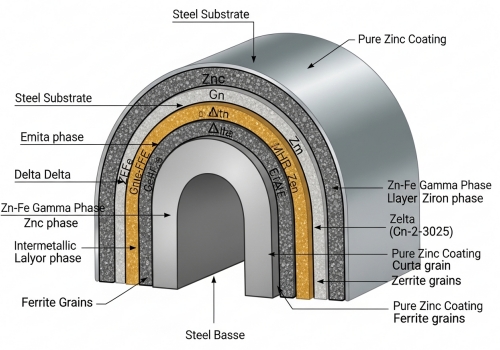

I have been in the steel industry since 1996. I have seen many factories try to cut corners. But at Finego Steel, we know that the process is strictly defined. Making a hot dip galvanized steel pipe is a mix of physics and chemistry. It is not simple. First, we must remove every bit of oil and rust from the bare pipe. If the steel is dirty, the zinc will not stick. We use a process called pickling. We dip the pipe in acid. Then, we wash it. The most important step happens next. We dip the pipe into a kettle of molten zinc. The temperature is very high, usually about 450°C (840°F). When the steel touches the hot zinc, something amazing happens. The iron in the steel reacts with the zinc. They mix together. They form a new material called a zinc-iron alloy. This is not like paint that just sits on top. This alloy is part of the pipe itself. The outer layer is pure zinc. This gives you two layers of protection. First, a hard alloy layer. Second, a smooth zinc layer. This makes the pipe very strong against physical damage during shipping or installation.

| Step | Action | Purpose |

|---|---|---|

| 1 | Degreasing | Removes oil and organic dirt. |

| 2 | Pickling | Removes mill scale and rust using acid. |

| 3 | Fluxing | Prevents oxidation before dipping. |

| 4 | Galvanizing | Dipping in molten zinc at 450°C. |

| 5 | Quenching | Cooling the pipe to set the coating. |

| 6 | Inspection | Checking thickness and appearance. |

What is the difference between hot dip and cold galvanized pipes?

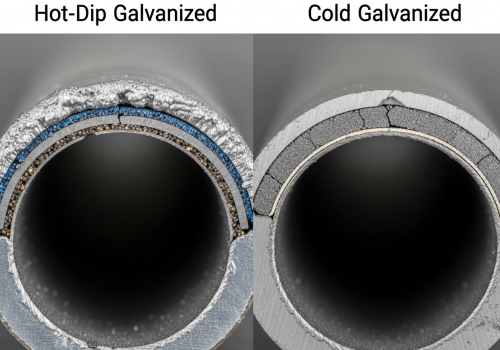

Are you confused by the price difference between two pipes that look almost the same? Choosing the cheaper "cold" option now could cost you ten times more in replacement costs later. Hot dip galvanizing involves dipping the pipe in hot liquid zinc for a thick, bonded shell. Cold galvanizing is simply electro-plating a thin layer of zinc onto the surface. Hot dip is much stronger, thicker, and lasts much longer than cold types.

This is the most common question I get from purchasing managers. I remember a client from an EPC company in Germany. He was looking at two quotes. One was for hot dip galvanized steel pipe and one was for cold galvanized (or electro-galvanized) pipe. The cold one was cheaper. He almost bought it for an outdoor project. I had to stop him. Here is the truth. Cold galvanizing puts a very thin layer of zinc on the pipe. It uses electricity to do this. The layer is usually only 5 to 15 microns thick. It looks shiny and smooth. But it is weak. It is good for small screws or indoor parts. It is bad for big pipes. Hot dip galvanizing is different. The zinc layer is very thick. It is usually 35 to 85 microns or even more. It is duller and maybe a bit rougher. But it is a tank. The zinc bonds chemically with the steel. In cold galvanizing, the zinc just holds on to the surface like a sticker. If you use cold galvanized pipes outside, they will rust in a few years. Hot dip pipes will last for decades. For construction and fluid transport, you must use hot dip. The initial cost is higher, but the lifetime cost is much lower.

| Feature | Hot Dip Galvanized | Cold Galvanized (Electro) |

|---|---|---|

| Zinc Thickness | Thick (35-650 μm) | Thin (5-15 μm) |

| Bond Type | Metallurgical (Chemical) | Physical (Adhesion) |

| Appearance | Dull, rougher grey | Shiny, smooth silver |

| Durability | Very High (decades) | Low (years) |

| Best Use | Outdoor, Structural, Piping | Indoor, Screws, Small parts |

How long does a hot dip galvanized steel pipe really last?

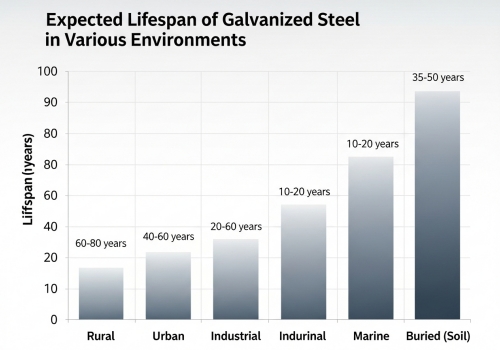

Do you worry about having to shut down your facility for maintenance repairs in just a few years? You need a material that protects itself so you can focus on other important work. These pipes have an incredibly long lifespan, lasting over 100 years in rural areas and 20 to 50 years in harsh industrial or marine environments. This is due to the sacrificial nature of zinc, which corrodes to save the steel.

The lifespan of a hot dip galvanized steel pipe is one of its best features. I always tell my customers that this is an investment in the future. The length of time it lasts depends on where you put it. But in almost all cases, it beats other materials. Why does it last so long? It is because of "cathodic protection." This is a technical term, but the idea is simple. Zinc is more active than steel. If the coating gets a scratch, the zinc around the scratch will sacrifice itself. The zinc corrodes first to save the steel underneath. It is like a self-healing wound. Paint cannot do this. If paint scratches, the steel rusts immediately. In a clean country environment, these pipes can last more than 100 years. That is longer than most buildings. In a city, they last about 30 years or more. Even in heavy industrial areas with pollution, or near the ocean with salt air, they last 20 to 50 years. We supply pipes to oil and gas companies like Shell and CNPC. They use them in very tough conditions. They choose hot dip galvanizing because they do not want to do maintenance. Once you install it, you can forget about it. It solves the rust problem completely.

| Environment | Estimated Lifespan |

|---|---|

| Rural / Suburban | 50 - 100+ Years |

| Urban / City | 30 - 50 Years |

| Marine / Coastal | 25 - 50 Years |

| Heavy Industrial | 20 - 40 Years |

Conclusion

Hot dip galvanized steel pipe is the best choice for long-term protection against rust, offering a thick, self-healing zinc shield that saves you money and ensures safety for decades.

Language

Language