- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

-

When it comes to modern construction and industrial applications, Structural Steel Pipe stands out as a fundamental building block. If you're looking for a reliable pipe steel structure solution, understanding the benefits and applications of quality structural steel pipe is crucial.2025-04-14

When it comes to modern construction and industrial applications, Structural Steel Pipe stands out as a fundamental building block. If you're looking for a reliable pipe steel structure solution, understanding the benefits and applications of quality structural steel pipe is crucial.2025-04-14 -

When it comes to industrial piping solutions, the seamless carbon steel pipe stands out as a reliable and high-performance option. Known for its durability, strength, and resistance to high pressure, this type of pipe is widely used in oil and gas, construction, and chemical processing industries.2025-04-09

When it comes to industrial piping solutions, the seamless carbon steel pipe stands out as a reliable and high-performance option. Known for its durability, strength, and resistance to high pressure, this type of pipe is widely used in oil and gas, construction, and chemical processing industries.2025-04-09 -

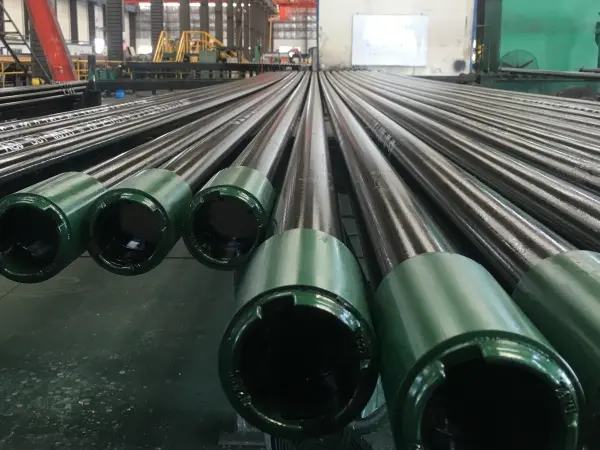

When it comes to oil and gas drilling, OCTG pipe (Oil Country Tubular Goods) plays a crucial role in ensuring efficient and safe extraction. If you're wondering "what is OCTG pipe?", this guide will explain its meaning, types, dimensions, and why it's essential in the energy sector.2025-04-07

When it comes to oil and gas drilling, OCTG pipe (Oil Country Tubular Goods) plays a crucial role in ensuring efficient and safe extraction. If you're wondering "what is OCTG pipe?", this guide will explain its meaning, types, dimensions, and why it's essential in the energy sector.2025-04-07 -

A drill bit stop collar is a small but essential accessory that helps control drilling depth, ensuring precision in woodworking, metalworking, and construction projects. If your drill bit stop collar isn’t working correctly, follow these troubleshooting tips to fix common problems.2025-04-05

A drill bit stop collar is a small but essential accessory that helps control drilling depth, ensuring precision in woodworking, metalworking, and construction projects. If your drill bit stop collar isn’t working correctly, follow these troubleshooting tips to fix common problems.2025-04-05 -

Heavy weight drill pipe is an indispensable tool in modern drilling operations. In this article, we explore the key features, benefits, and applications of heavy weight drill pipe in the oil and gas industry.2025-04-02

Heavy weight drill pipe is an indispensable tool in modern drilling operations. In this article, we explore the key features, benefits, and applications of heavy weight drill pipe in the oil and gas industry.2025-04-02 -

Supercritical fluid (SCF) pipelines are used in high-efficiency power plants, CO₂ sequestration, and aerospace propulsion, requiring seamless pipes with high-pressure endurance, corrosion resistance, and thermal stability.2025-03-28

Supercritical fluid (SCF) pipelines are used in high-efficiency power plants, CO₂ sequestration, and aerospace propulsion, requiring seamless pipes with high-pressure endurance, corrosion resistance, and thermal stability.2025-03-28 -

Fusion reactors, such as ITER, use liquid metal or supercritical water cooling systems, requiring seamless pipes with extreme high-temperature resistance and radiation tolerance.2025-03-26

Fusion reactors, such as ITER, use liquid metal or supercritical water cooling systems, requiring seamless pipes with extreme high-temperature resistance and radiation tolerance.2025-03-26 -

With the rise of the hydrogen economy, high-pressure hydrogen transportation pipelines have become a critical challenge. Seamless pipes, due to their absence of welds, uniform microstructure, and excellent crack resistance, are considered an ideal choice for hydrogen transport.2025-03-24

With the rise of the hydrogen economy, high-pressure hydrogen transportation pipelines have become a critical challenge. Seamless pipes, due to their absence of welds, uniform microstructure, and excellent crack resistance, are considered an ideal choice for hydrogen transport.2025-03-24 -

OCTG (Oil Country Tubular Goods) are specialized pipes used in the oil and gas industry to extract hydrocarbons from underground reservoirs. These pipes play a crucial role in ensuring the safety, integrity, and efficiency of oil and gas wells throughout their life cycle. Different types of OCTG are designed for specific applications and functions, depending on the conditions encountered during drilling and production.2025-03-21

OCTG (Oil Country Tubular Goods) are specialized pipes used in the oil and gas industry to extract hydrocarbons from underground reservoirs. These pipes play a crucial role in ensuring the safety, integrity, and efficiency of oil and gas wells throughout their life cycle. Different types of OCTG are designed for specific applications and functions, depending on the conditions encountered during drilling and production.2025-03-21 -

The manufacturing process of OCTG involves several key steps to ensure the final product meets stringent industry standards. From raw material selection to final inspection, each stage plays a vital role in ensuring the strength, integrity, and reliability of the OCTG during oil extraction operations.2025-03-19

The manufacturing process of OCTG involves several key steps to ensure the final product meets stringent industry standards. From raw material selection to final inspection, each stage plays a vital role in ensuring the strength, integrity, and reliability of the OCTG during oil extraction operations.2025-03-19 -

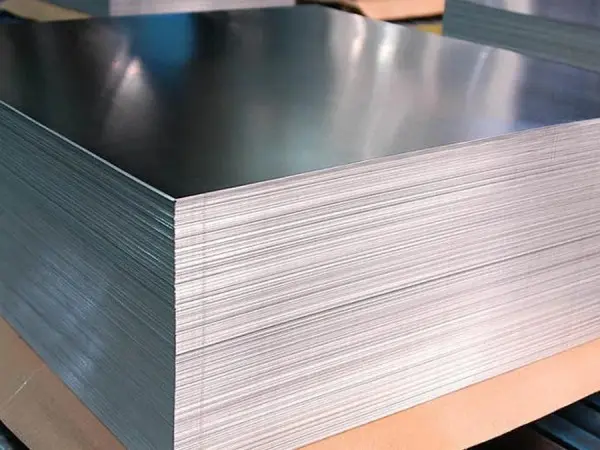

Oil casings are a critical component in the oil and gas industry, serving as protective barriers for wells during exploration and production. The materials used in the production of oil casings must meet stringent requirements to ensure strength, durability, and resistance to corrosion under harsh conditions. Common materials include carbon steel, alloy steel, and stainless steel, with each offering distinct advantages for different applications.2025-03-17

Oil casings are a critical component in the oil and gas industry, serving as protective barriers for wells during exploration and production. The materials used in the production of oil casings must meet stringent requirements to ensure strength, durability, and resistance to corrosion under harsh conditions. Common materials include carbon steel, alloy steel, and stainless steel, with each offering distinct advantages for different applications.2025-03-17 -

Geothermal energy plants use stainless steel piping for steam transport and reinjection wells, requiring resistance to extreme temperatures and aggressive geothermal fluids.2025-03-15

Geothermal energy plants use stainless steel piping for steam transport and reinjection wells, requiring resistance to extreme temperatures and aggressive geothermal fluids.2025-03-15 -

Aerospace applications require lightweight, high-strength stainless steel pipes for fuel lines, hydraulic systems, and exhaust components.2025-03-12

Aerospace applications require lightweight, high-strength stainless steel pipes for fuel lines, hydraulic systems, and exhaust components.2025-03-12 -

Ensuring the structural integrity of welded steel pipes is critical, especially for safety-critical applications like pressure vessels, oil rigs, and pipelines.2025-03-09

Ensuring the structural integrity of welded steel pipes is critical, especially for safety-critical applications like pressure vessels, oil rigs, and pipelines.2025-03-09 -

Hydrogen embrittlement (HE) is a severe issue affecting the integrity of welded pipes, particularly in oil & gas pipelines and hydrogen transport systems.2025-03-07

Hydrogen embrittlement (HE) is a severe issue affecting the integrity of welded pipes, particularly in oil & gas pipelines and hydrogen transport systems.2025-03-07

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from,This behavior is in compliance with the user consent policy.

Language

Language