- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

-

This guide will help you understand key factors in choosing the best API 5CT casing pipe for your oil well, including material grades, connection types, and environmental considerations.2025-07-17

This guide will help you understand key factors in choosing the best API 5CT casing pipe for your oil well, including material grades, connection types, and environmental considerations.2025-07-17 -

This article explores the key characteristics of steel pipe piles, their advantages, and common applications.2025-07-10

This article explores the key characteristics of steel pipe piles, their advantages, and common applications.2025-07-10 -

This guide breaks down each step of the FBE coating process, its benefits, and best practices for optimal pipeline protection.2025-07-03

This guide breaks down each step of the FBE coating process, its benefits, and best practices for optimal pipeline protection.2025-07-03 -

This guide will help you identify the best FBE coated pipe suppliers by covering key selection criteria, industry standards, and tips for ensuring high-quality purchases.2025-06-26

This guide will help you identify the best FBE coated pipe suppliers by covering key selection criteria, industry standards, and tips for ensuring high-quality purchases.2025-06-26 -

In this article, we will explore the properties, uses, and benefits of ASTM A105 pipe fittings, helping you understand why they are a preferred choice in critical applications.2025-06-24

In this article, we will explore the properties, uses, and benefits of ASTM A105 pipe fittings, helping you understand why they are a preferred choice in critical applications.2025-06-24 -

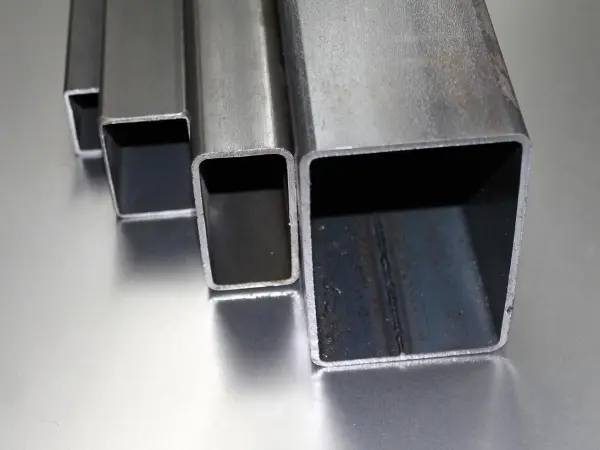

In this article, we will explore the manufacturing process, key advantages, and relevant industry standards for hot dip galvanized square and rectangular pipe.2025-06-10

In this article, we will explore the manufacturing process, key advantages, and relevant industry standards for hot dip galvanized square and rectangular pipe.2025-06-10 -

Discover the differences between square galvanized pipe and galvanized round pipe. Learn which is best for fencing, plumbing, or construction based on strength, uses, and installation. Make the right choice for your project!2025-06-03

Discover the differences between square galvanized pipe and galvanized round pipe. Learn which is best for fencing, plumbing, or construction based on strength, uses, and installation. Make the right choice for your project!2025-06-03 -

Discover the key differences between pipe bend vs elbow in piping systems. Learn their applications, advantages, and when to use each for optimal flow efficiency and cost-effectiveness.2025-05-29

Discover the key differences between pipe bend vs elbow in piping systems. Learn their applications, advantages, and when to use each for optimal flow efficiency and cost-effectiveness.2025-05-29 -

Learn how to prevent delamination in square and rectangular steel tubes with 6 proven strategies—from material selection to quality control. Ensure durable, high-performance steel tubes for industrial use.2025-05-22

Learn how to prevent delamination in square and rectangular steel tubes with 6 proven strategies—from material selection to quality control. Ensure durable, high-performance steel tubes for industrial use.2025-05-22 -

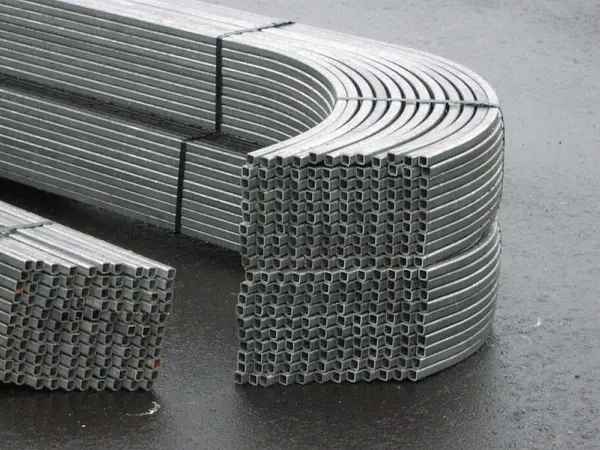

Discover the differences between solid bending & air bending for rectangular square tube forming. Learn their pros, cons, and best applications for precision fabrication.2025-05-20

Discover the differences between solid bending & air bending for rectangular square tube forming. Learn their pros, cons, and best applications for precision fabrication.2025-05-20 -

Learn how to polish galvanized steel pipe effectively with 7 professional methods—mechanical grinding, chemical polishing, ultrasonic finishing & more. Get a smooth, corrosion-resistant finish!2025-05-15

Learn how to polish galvanized steel pipe effectively with 7 professional methods—mechanical grinding, chemical polishing, ultrasonic finishing & more. Get a smooth, corrosion-resistant finish!2025-05-15 -

Discover the key advantages of 3PE coated steel pipe, including long service life, excellent thermal insulation, and superior corrosion resistance. Learn why it’s the top choice for durable and cost-effective pipeline solutions.2025-05-08

Discover the key advantages of 3PE coated steel pipe, including long service life, excellent thermal insulation, and superior corrosion resistance. Learn why it’s the top choice for durable and cost-effective pipeline solutions.2025-05-08 -

Learn essential heat treatment methods for galvanized square tubes, including temperature charts, case studies, and best practices. Discover how to maintain structural integrity and corrosion resistance.2025-05-01

Learn essential heat treatment methods for galvanized square tubes, including temperature charts, case studies, and best practices. Discover how to maintain structural integrity and corrosion resistance.2025-05-01 -

Discover the process characteristics of galvanized round steel pipe, featuring high-efficiency sulfate zinc-iron alloy plating, superior corrosion resistance, and eco-friendly production. Learn how this method ensures fast deposition, bright coatings, and minimal environmental impact. Perfect for industrial applications!2025-04-22

Discover the process characteristics of galvanized round steel pipe, featuring high-efficiency sulfate zinc-iron alloy plating, superior corrosion resistance, and eco-friendly production. Learn how this method ensures fast deposition, bright coatings, and minimal environmental impact. Perfect for industrial applications!2025-04-22 -

In this guide, we’ll break down the I beam vs H beam debate, exploring their unique characteristics, advantages, and best use cases. Whether you're working on a skyscraper, a bridge, or an industrial project, choosing the right beam can impact stability, cost, and efficiency.2025-04-16

In this guide, we’ll break down the I beam vs H beam debate, exploring their unique characteristics, advantages, and best use cases. Whether you're working on a skyscraper, a bridge, or an industrial project, choosing the right beam can impact stability, cost, and efficiency.2025-04-16

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from,This behavior is in compliance with the user consent policy.

Language

Language