- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Heat Treatment Knowledge for Galvanized Square Tubes: Essential Methods and Processes

When working with galvanized square tubes, proper heat treatment is crucial to maintain their structural integrity and corrosion resistance. This guide covers key heat treatment methods for steel and best practices specifically for galvanized square tube applications, supported by real-world case studies and temperature charts.

Preparation Before Heat Treatment

1. Surface Cleaning

· Remove oil, residual salts, paint, and other contaminants from galvanized square tubes and fixtures before heat treatment.

· Use appropriate cleaning methods: alkaline washing, water-soluble cleaners, chlorinated solvents, sandblasting, or shot blasting.

2. Vacuum Furnace Requirements

· Fixtures used in vacuum furnaces must be pre-degassed and cleaned at a vacuum level not lower than the workpiece requirement.

Heat Treatment Process of Steel for Galvanized Tubes

1. Preheating Methods

· For easily deformable workpieces: Heat on special fixtures with controlled heating rates.

o First preheat: 800°C

o Second preheat: 500-550°C and 850°C

· Complex-shaped workpieces: Mandatory preheating for components with significant cross-sectional changes or large effective thickness.

2. Heating and Soaking

· Determine soaking time based on the tube's effective thickness and "condition thickness" (actual thickness × shape factor coefficient).

· Avoid salt bath heating for:

o Workpieces with blind holes

o Castings and welded components

o Machined stainless steel parts

3. Post-Treatment Procedures

· Martensitic stainless/heat-resistant steel tubes:

o Clean after quenching to room temperature

o Perform cryogenic treatment or tempering within 4 hours of welding

· Stress relief:

o Anneal below original tempering temperature after straightening

o Use shaping fixtures during tempering for complex components

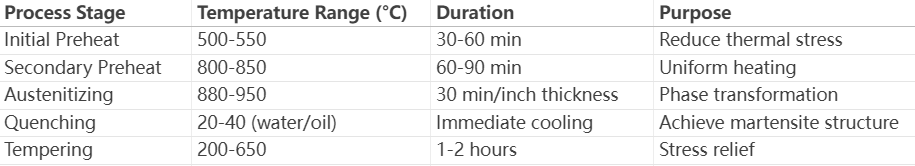

Temperature Charts for Galvanized Square Tube Heat Treatment

Note: Temperatures may vary ±15°C based on specific alloy composition

Key Considerations in Steel Heat Treatment Methods

1. Temperature Control

o Strictly monitor heating/cooling rates for galvanized surfaces

o Maintain furnace atmosphere to prevent zinc layer damage

2. Quality Verification

o Hardness testing

o Microstructure analysis

o Coating adhesion checks

Industry Applications

These heat treatment process of steel techniques are vital for:

· Construction frameworks using galvanized square tubes

· Automotive chassis components

· Industrial equipment manufacturing

By following these methods of steel heat treatment, manufacturers can optimize the performance of galvanized square tubing while preserving its anti-corrosion properties. The included temperature charts and case studies demonstrate practical implementation scenarios. For specialized applications, always consult metallurgical experts to customize the thermal processing parameters.

Language

Language