- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Square Galvanized Pipe vs. Round Galvanized Pipe: Which Is Best for Your Project?

When choosing between square galvanized pipe and galvanized round pipe, understanding their structural differences and applications is crucial. Both types feature zinc coating for superior corrosion resistance, but their distinct shapes make each suitable for specific uses. This comprehensive guide will help you determine the ideal choice for your construction, industrial, or decorative needs.

1. Understanding Square Galvanized Pipe

A square galvanized pipe is a hollow structural section (HSS) with four equal sides and 90-degree angles. The hot-dip galvanizing process creates a zinc-iron alloy coating that provides exceptional protection against rust and environmental damage.

Key Advantages of Square Galvanized Pipe:

✔ Superior Structural Integrity – The flat surfaces and right-angle corners provide excellent load-bearing capacity, making it ideal for frameworks and support systems.

✔ Enhanced Fabrication Ease – The straight edges simplify welding, drilling, and bolting compared to round pipes.

✔ Modern Aesthetic – Offers clean lines and a contemporary appearance for architectural applications.

✔ Space Efficiency – The square shape allows for tighter packing and more efficient storage/transport.

Top Applications:

· Structural frameworks for buildings and machinery

· Heavy-duty fencing and security barriers

· Handrails, guardrails, and balcony systems

· Industrial shelving and storage solutions

· Automotive and trailer components

2. Exploring Galvanized Round Pipe

The galvanized round pipe features a traditional cylindrical shape with uniform wall thickness. Like its square counterpart, it receives zinc coating through hot-dip or electroplating processes for corrosion protection.

Key Advantages of Galvanized Round Pipe:

✔ Optimal Fluid Dynamics – Smooth interior walls minimize friction for efficient liquid/gas flow.

✔ Uniform Stress Distribution – Circular cross-section evenly handles internal/external pressures.

✔ Greater Flexibility – Can be bent or curved for custom installations when needed.

✔ Proven Durability – Excellent resistance to impact and environmental stressors.

Primary Applications:

· Plumbing systems and water distribution

· Natural gas and propane line installations

· Electrical conduit and cable protection

· Scaffolding and temporary structures

· Agricultural irrigation systems

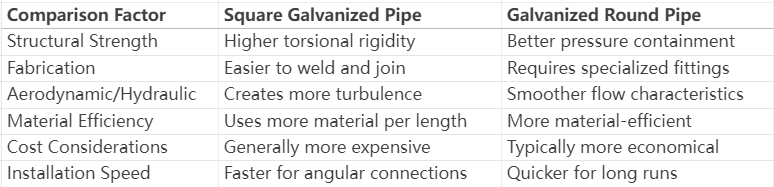

3. Critical Comparison: Square vs. Round Galvanized Pipes

4. How to Select the Right Pipe for Your Project

When to Choose Square Galvanized Pipe:

· Building structural frames requiring right-angle connections

· Projects demanding a modern, architectural appearance

· Applications needing maximum rigidity and load capacity

· Situations where easy bolting/welding is essential

When Galvanized Round Pipe is Preferable:

· Fluid transport systems (water, gas, oil)

· Electrical wiring protection

· Projects requiring bent or curved sections

· High-pressure environments

5. Expert Recommendations

For most construction projects involving structural frameworks or decorative elements, square galvanized pipe offers unbeatable advantages in strength and aesthetics. However, for plumbing, electrical, or fluid transport applications, galvanized round pipe remains the industry standard.

Still unsure which solution best fits your requirements? Contact our experts today! Our team of piping specialists can provide personalized recommendations based on your project specifications, budget, and performance needs. We offer premium-quality square galvanized pipe and galvanized round pipe options to meet any industrial or construction demand.

Language

Language