- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Industry News

Why Stainless Steel Welded Pipes Are Essential for Water Treatment Systems

Water treatment systems are critical for ensuring safe drinking water, efficient wastewater management, and sustainable industrial processes. One of the most vital components in these systems is the stainless welded steel pipe, which offers unmatched durability, corrosion resistance, and long-term reliability.

In this article, we explore why stainless welded steel pipes are the preferred choice for water treatment applications, their key benefits, and how they outperform alternative materials.

1. Superior Corrosion Resistance for Harsh Environments

Water treatment plants handle aggressive chemicals, high salinity, and varying pH levels. Unlike carbon steel or plastic pipes, stainless welded steel pipes provide exceptional resistance to:

· Chlorides & Disinfectants – Common in water purification, these can corrode traditional pipes.

· Acidic & Alkaline Solutions – Used in pH adjustment processes.

· Saltwater Exposure – Critical for desalination plants.

Grades like 304, 316, and 2205 duplex stainless steel are commonly used, with 316L offering enhanced protection against pitting and crevice corrosion.

2. Durability & Long Service Life

Water treatment infrastructure must last decades without failure. Stainless welded steel pipes excel due to:

· High Tensile Strength – Withstands high-pressure water flow and external stresses.

· Temperature Resistance – Performs well in both extreme cold and hot water systems.

· Minimal Degradation – Unlike plastic pipes, stainless steel does not become brittle over time.

This longevity reduces maintenance costs and downtime, making it a cost-effective long-term investment.

3. Hygienic & Safe for Potable Water

Water purity is non-negotiable. Stainless steel is:

· Non-Toxic – Does not leach harmful chemicals (unlike PVC or lead-containing materials).

· Smooth Inner Surface – Prevents bacterial growth and biofilm formation.

· Easy to Clean & Sterilize – Ideal for pharmaceutical and food-grade water treatment.

Regulatory bodies like NSF, ANSI, and WHO approve stainless steel for drinking water applications.

4. Cost Efficiency Over the Long Term

While the initial cost of stainless welded steel pipes may be higher than alternatives, they offer:

· Lower Maintenance Costs – Resistant to scaling, rust, and chemical wear.

· Reduced Replacement Frequency – Lasts 50+ years with proper installation.

· Energy Efficiency – Smooth interior reduces pumping resistance, saving energy.

5. Versatility in Water Treatment Applications

Stainless welded steel pipes are used across multiple stages of water treatment:

A. Drinking Water Treatment

· Filtration Systems – Resistant to chlorine and ozone disinfection.

· Distribution Networks – Ensures clean water delivery without contamination.

B. Wastewater & Sewage Treatment

· Sludge Handling – Resists abrasive and corrosive waste materials.

· Chemical Dosing Lines – Handles sulfuric acid, sodium hydroxide, and other treatment chemicals.

C. Industrial Water Systems

· Cooling & Boiler Systems – Withstands high temperatures and pressure.

· Desalination Plants – Resists salt-induced corrosion in seawater applications.

6. Environmental Sustainability

Stainless steel is 100% recyclable, making it an eco-friendly choice. Its durability also reduces material waste compared to frequently replaced plastic or concrete pipes.

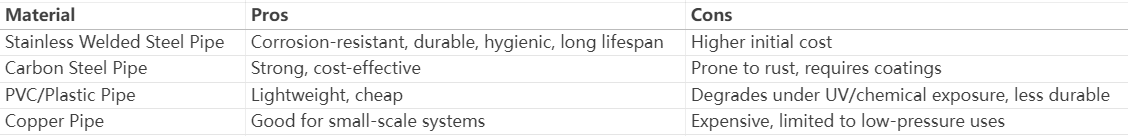

7. Comparing Stainless Welded Steel Pipes to Alternatives

Conclusion: Why Choose Stainless Welded Steel Pipes?

For water treatment systems that demand reliability, safety, and efficiency, stainless welded steel pipes are the optimal choice. Their corrosion resistance, strength, and hygienic properties make them indispensable in modern water infrastructure.

By investing in high-quality stainless welded steel pipes, municipalities, industries, and engineering firms can ensure long-lasting, sustainable, and contamination-free water distribution.

FAQs

Q: What grade of stainless steel is best for water treatment?

A: 316L is ideal for most applications due to its molybdenum content, which enhances corrosion resistance. For highly corrosive environments, duplex stainless steel (2205) is recommended.

Q: Can stainless welded pipes handle high-pressure water flow?

A: Yes, stainless steel pipes have high burst pressure ratings, making them suitable for high-pressure systems.

Q: Are stainless steel pipes more expensive than PVC?

A: Initially, yes—but their long lifespan and low maintenance make them more cost-effective over time.

Q: How do you maintain stainless steel pipes in water treatment?

A: Regular inspections and cleaning with mild detergents are usually sufficient, thanks to their corrosion-resistant properties.

Language

Language