- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What Is a Precision Steel Pipe and Why Is It Essential for Your Projects?

You struggle to find pipes that fit your designs perfectly. Poor quality materials cause delays and cost money, which is a big problem for any project manager. Precision steel pipe is a specific type of seamless or welded tube known for its high dimensional accuracy and smooth surface finish. It is usually produced through cold drawing or hot rolling processes to ensure strict tolerances, high pressure resistance, and no oxide coating, making it ideal for hydraulic systems.

I have worked in this industry since 1996, and I know that choosing the right pipe is not easy. There are many technical details to consider. Today, I want to share my knowledge with you. This article will help you understand the value of these pipes.

How Is Precision Steel Pipe Manufactured to Ensure High Quality?

Bad manufacturing processes lead to cracks and weak spots in pipes. You cannot afford to have equipment fail because the materials were not made correctly. To ensure quality, manufacturers use specific steps like annealing and cold rolling. This process creates a denser metal structure with better surface quality than standard hot-rolled pipes.

The Manufacturing Process Explained

I want to explain the process so you can see why precision steel pipe is different from normal pipe. The key to making these pipes is the treatment of the raw material. It starts with a round steel billet. We inspect this raw material carefully to remove any defects. First, we heat the material and perform hot rolling. This is the basic step. However, for precision pipes, we must go further. We use a process called pickling to remove impurities. Then, we apply lubrication and dry the pipe. The most important step is cold rolling or cold drawing. This is more complex than hot rolling. We often use a three-roller continuous rolling method. This squeezes the steel to exact sizes. After the rolling, we remove the oil and cut the ends. Finally, every pipe goes through strict inspection. This ensures that the precision steel pipe has a high density and superior performance. As a supplier, I ensure that our factories follow these steps strictly. This process eliminates the oxide coating on the surface. It ensures that the pipe can handle cold bending without reforming or cracking. This detailed process is why these pipes are reliable for your EPC projects.

What Are the Standards and Tolerances You Need to Know?

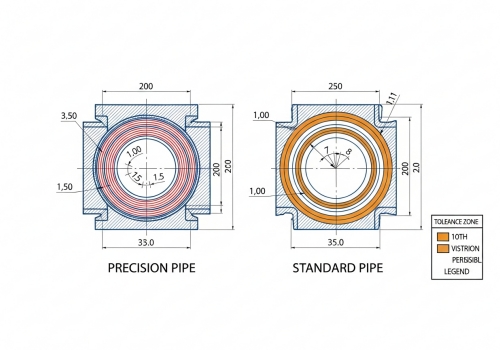

Confusing standards can lead to ordering the wrong parts for your machinery. This wastes your time and your project budget. The main international standard is DIN 2391, but ASTM A106 and EN10305 are also common. Tolerances vary by size, often ranging from +/- 0.05mm to +/- 0.1%, depending on the diameter.

Standards and Size Data

In my experience with global customers, knowing the standard is vital. The most common standard for precision steel pipe is DIN 2391. This is a European standard. However, we also work with many other standards depending on where you are. We can supply pipes based on DIN 2445, EN 10305, and DIN 1630. For American projects, we use ASTM A106 or ASTM A179. The materials we use include 10#, 20#, 35, and 45 steel grades. We also use alloy grades like 40Cr and 25Mn. The most critical part for you is the tolerance. This is the difference between the planned size and the actual size. Precision pipes have very small tolerances. I have created a table below to show you the tolerance rules for Cold Drawn Precision Pipes:

| Diameter Range (OD) | Normal Tolerance | Premium Tolerance |

|---|---|---|

| 6mm to 10mm | +/- 0.20% | +/- 0.15% |

| 10mm to 30mm | +/- 0.40% | +/- 0.20% |

| 30mm to 50mm | +/- 0.45% | +/- 0.30% |

| Above 50mm | +/- 1.00% | +/- 0.80% |

For hot-rolled precision pipes, the tolerance is usually around +/- 0.1%. These numbers show why these pipes fit perfectly into machines. You do not need to do much machining work on them. This saves you labor costs. When I help customers sourcing these items, I always check these numbers first.

Why Should You Choose Precision Pipes Over Normal Pipes?

Heavy pipes increase shipping costs and add unnecessary weight to your structures. You need a lighter, stronger solution that is easy to install. Precision pipes offer a high strength-to-weight ratio. They withstand high pressure without leaking and resist bending, making them perfect for automotive parts, hydraulic cylinders, and construction machinery.

Features and Applications

You might ask, "Why should I pay for precision?" The answer lies in the features. A precision steel pipe has a very smooth surface inside and out. It has no oxide layer. This means it will not rust easily during storage. Also, it can bear high pressure without leaking. This is crucial for safety in oil and gas projects. Another great feature is the mechanical behavior. You can bend these pipes cold, and they will not deform or crack. We perform flaring and flattening tests to prove this. Because of these features, the applications are vast. They are lighter than solid bars but have the same bending strength. This makes them efficient. We see them used widely in:

1. Hydraulic Systems: The smooth inside surface is perfect for oil flow.

2. Automotive Industry: They are used for making parts that need to be strong but light.

3. Construction: Used for steel structures and scaffolding where safety is key.

4. Military: Used for conventional weapons and barrels due to high precision. At Finego Steel, we supply these pipes to top companies like CNPC and Shell. We see that switching to precision pipes helps them reduce the weight of their equipment. It also saves material costs because the pipes are so accurate. You do not waste metal cutting them down to size.

Conclusion

Precision steel pipes provide exact dimensions, smooth surfaces, and high strength. They save you money and ensure safety. I am here to help you find the best solution.

Language

Language