- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Seamless Steel Pipe

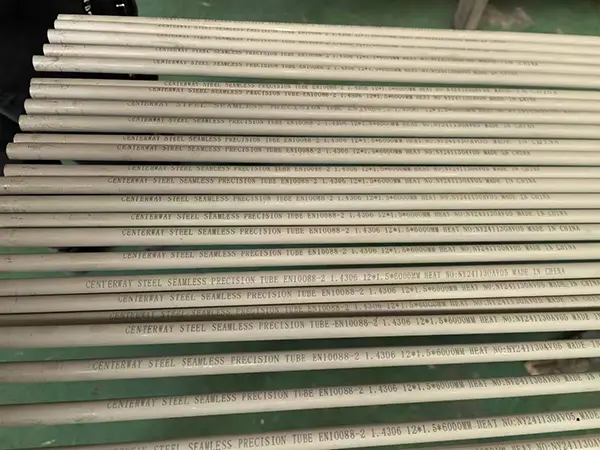

Precision Steel Pipe

Precision steel pipe is a kind of common seamless steel pipe (or reduced diameter welded steel pipe) through fine drawing or cold rolling processing after a high precision steel pipe material.

Product: seamless precision pipe, precision steel pipe, seamless precision tube

Application: used for mechanical structures,hydraulic equipment,automative parts

Size: od: 6mm-114mm; wt: 0.5mm - 60mm; length: 5.8/6/11.8/12m

Pipe Standard: EN 10305, ASTM A106-2006, BS 1139, DIN 2391, DIN 2445

Standard

- API Spec 5L

- ASTM A53/A53M

- ASTM A106/A106M

- ASTM A213/A213M

- ASTM A312/A312M

- ASTM A333/A333M

- ASTM A335/A335M

- ASME SA53/SA53M

- ASME SA106/SA106M

- ASME SA213/SA213M

- ASME SA312/SA312M

- ASME SA333/SA333M

- ASME SA335/SA335M

- EN 10210

- EN 10216-2

- EN 10217

- EN 10219

- JIS G3441

- JIS G3444

- JIS G3445

- JIS G3452

- JIS G3456

- JIS G3457

Specification

Precision steel pipe is a kind of common seamless steel pipe (or reduced diameter welded steel pipe) through fine drawing or cold rolling processing after a high precision steel pipe material. Because the inner and outer walls of the precision bright tube have no oxide layer, no leakage under high pressure, high precision, high finish, no deformation in cold bending, flaring, flattening and no cracks, it is mainly used to produce pneumatic or hydraulic components, such as cylinders or cylinders, which can be seamless tubes or welded tubes.

The chemical composition of precision bright tube is carbon C, silicon Si, Manganese Mn, sulfur S, phosphorus P, chromium Cr. High quality carbon steel, finished rolling, no oxidation bright heat treatment (NBK state), non-destructive testing, the inner wall of the steel pipe is SCrubbed by special equipment and washed by high pressure, the antirust oil on the steel pipe is used for antirust treatment, and the two ends of the cover is used for dustproof treatment. The inner and outer wall of the steel tube is of high precision, high finish, no oxide layer of the steel tube after heat treatment, high cleanliness of the inner wall, the steel tube is under high pressure, no deformation in cold bending, no cracks in flaring and flattening.

Application:

Automobile, mechanical parts, such as steel pipe precision, finish has high requirements of machinery. Precision steel pipe users are not only the users with high requirements for precision and finish, because the precision bright pipe is high, the tolerance can be maintained at 2-8 wire, so many mechanical processing users in order to save the loss of labor, material and time, the seamless steel pipe or round steel is slowly transformed into precision bright pipe.

Characteristics:

1. The outer diameter is smaller.

2. High precision can be used for small batch production.

3. Cold-drawn products have high precision and good surface quality.

4. The transverse area of steel tube is more complex.

5. Steel pipe has better performance and denser metal.

6. Cold-drawn products have high precision and good surface quality.

7. The transverse area of steel tube is more complex.

8. Steel pipe has better performance and denser metal.

|

Thickness |

0.5mm - 60mm |

Alloy Or Not |

Non-Alloy |

|

Section Shape |

Round 10.3mm - 610mm |

Tolerance |

±5% |

|

Place of Origin |

China |

Payment terms |

L/C T/T (30%DEPOSIT) |

|

Application |

Used for Mechanical Structures,Hydraulic Equipment,Automative Parts,structure/fluid/boiler/water and gas etc |

Packing |

STANDARD PACKING |

|

Technique |

Cold Drawn |

Inspection |

Party Inspection |

|

Surface Treatment |

oiled/black painting,NBK(+N) GBK(+A) BK(+C) BKW(+LC) BKS(+SR) |

Price term |

CIF CFR FOB EX-WORK |

|

Standard |

EN 10305,,DIN 2391,DIN 2445 ASTM A106-2006, ASTM A53-2007, ANSI A210-1996, ASTM A179-1990, BS 1139, BS 6323, DIN 1626, DIN 1629/4, DIN 2391, DIN 17175, DIN2448 ,GB/T8162, Gb/t8163, JIS G3459-2004, JIS G3456-2004 |

||

|

Grade |

STKM11A,STKM12B,STKM13A,10#, 20#, 45#, A53(A,B), A106(B,C), A179-C, ANSI4130 ,15Mo3, Q345, Q195, ST52, ST45, St37-2, ST35.4, ST35.8, ST54, 15crmo, 12Cr1MoV, API L80 |

||

|

Special Pipe |

API Pipe |

||

|

Type |

Seamless Steel Pipe |

||

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

||

|

Product name |

DIN2391 ST35 ST45 ST52 Cold Drawn High Precision Tube |

||

|

Material |

DIN2391 ST35 ST45 ST52 |

||

|

Keyword |

DIN2391 ST35 ST45 ST52 Cold Drawn High Precision Tube |

||

|

Surface |

Cold finished |

||

|

Outside Diameter (mm) / Wall Thickness (mm) |

SCH 10 |

SCH 20 |

SCH 30 |

STD |

SCH 40 |

SCH 60 |

XS |

SCH 80 |

SCH 100 |

SCH 120 |

SCH 140 |

SCH 160 |

|

457 |

6.35 |

7.92 |

11.13 |

9.53 |

14.27 |

19.05 |

12.70 |

23.88 |

29.36 |

34.93 |

39.67 |

45.24 |

|

508 |

6.35 |

9.53 |

12.70 |

9.53 |

15.09 |

20.62 |

12.70 |

26.19 |

32.54 |

38.10 |

44.45 |

50.01 |

|

559 |

6.35 |

9.53 |

12.70 |

9.53 |

|

22.23 |

12.70 |

28.58 |

34.93 |

41.28 |

47.63 |

53.98 |

|

610 |

6.35 |

9.53 |

14.27 |

9.53 |

17.48 |

24.61 |

12.70 |

30.96 |

38.39 |

46.02 |

52.37 |

59.54 |

|

660 |

7.92 |

12.70 |

|

9.53 |

|

|

12.70 |

|

|

|

|

|

|

711 |

7.92 |

12.70 |

15.88 |

9.53 |

|

|

12.70 |

|

|

|

|

|

|

762 |

7.92 |

12.70 |

15.88 |

9.53 |

|

|

12.70 |

|

|

|

|

|

|

Remark: The above standard and specification are just for reference, we can also produce customized product according to customer's request. |

||||||||||||

Process

As we know, most of precision steel pipe has cold drawn and hot rolled process. On the contrast, cold rolling will be more complicated. Not only the pipe need to be continuous rolled by three roller, but also the test have to be done after extrusion, so to guarantee the quality of the precision pipe materials.

Manufacturing methods of seamless precision pipe includes hot rolling and cold drawn. More over it could be manufactured in welding processes.

Language

Language