- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Industry News

How Long Does Epoxy Pipe Lining Last?

Dealing with corroded pipelines can be a nightmare for your project timeline. Constant leaks and repairs drain your budget, but epoxy lining offers a permanent, worry-free solution to these common headaches. You might wonder, how long does epoxy pipe lining last? Generally, it lasts between 30 to 50 years. In optimal industrial conditions with high-quality resin, this lifespan can extend up to 100 years, making it a superior choice for long-term infrastructure stability.

While knowing the lifespan is important, understanding why it lasts so long is crucial for your purchasing decision. Let’s look at the factors that actually determine this durability so you can make the right choice for your project.

What Factors Influence the Durability of the Lining?

Not all pipe linings are created equal, and making a blind choice can lead to early failure. You need to understand the specific elements that guarantee a long service life for your pipelines. The lifespan depends heavily on surface preparation, resin quality, and the application method. Proper cleaning and correct curing temperatures ensure the lining bonds correctly to the host pipe, preventing delamination and extending the service life significantly.

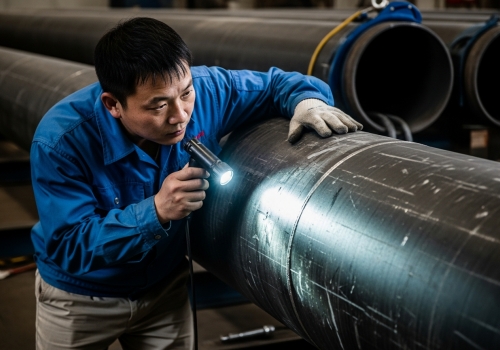

To truly understand how long does epoxy pipe lining last, we must look at the variables involved in the installation. As an expert in steel pipes, I see many projects fail not because of the material, but because of poor preparation. The bond between the epoxy and the original steel or concrete pipe is the most critical factor. If the original pipe is not cleaned using hydro-jetting or sandblasting to remove all rust and debris, the epoxy will peel off within a few years. In the pipeline industry, we often refer to surface preparation standards like ISO 8501. The surface usually needs to be cleaned to a "near-white metal" finish. This allows the resin to mechanically grip the surface. Furthermore, the type of resin matters immensely. In the industrial sector, we use different epoxies for water, oil, or gas. Some are designed for high heat, while others are designed for chemical resistance. If you use a standard water-grade epoxy for an oil pipeline, it will degrade quickly. Here is a breakdown of factors affecting longevity:

| Factor | Impact on Lifespan | Recommendation |

|---|---|---|

| Surface Prep | High | Must be cleaned to remove all scale and rust. |

| Resin Type | High | Must match the transported fluid (pH, temperature). |

| Curing Process | Medium | Hot water or steam curing is faster and harder than ambient curing. |

| Pipe Material | Low | Epoxy bonds well to steel, iron, and concrete if prepped right. |

By controlling these factors, you ensure the lining reaches that 50 to 100-year benchmark.

How Does the Installation Process Actually Work?

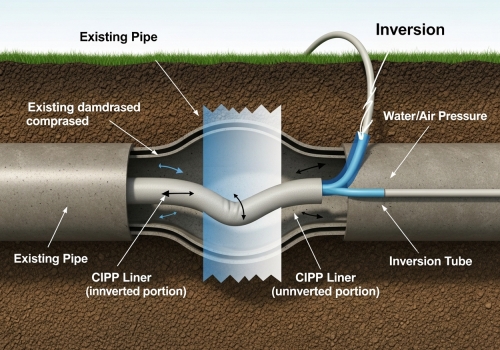

You cannot trust a solution if you do not understand the mechanics behind it. Blind trust leads to project errors, so I will explain the technical steps clearly to help you visualize the work. The process involves inspection, cleaning, and coating. A liner saturated with epoxy resin is inserted into the pipe and cured in place. This creates a smooth, jointless new pipe inside the old one, restoring structural integrity without digging.

The process, often called CIPP (Cured-In-Place Pipe), is a marvel of modern engineering. For an EPC manager like you, the biggest advantage is the "trenchless" aspect. We don't need to tear up the ground. First, we use a robotic camera to inspect the line. This fits perfectly with the CAD designs you likely work with; we map the damage precisely to see if the pipe is structurally sound enough to be lined. Second, we clean. As mentioned before, we use high-pressure water or mechanical scrapers. This returns the pipe to its original diameter. You cannot line a pipe that is full of debris. Third is the inversion. Imagine a wet sock being turned inside out into the pipe. This "sock" is a felt liner soaked in epoxy. We use air or water pressure to push it through the pipe. Once it is in place, we circulate hot steam. This heat turns the liquid epoxy into a hard, solid plastic. This results in a "pipe within a pipe." It is seamless. Why is seamless important? Because joints are where leaks happen. By removing joints, we remove the weakest points of the pipeline. This seamless nature is a primary reason why the answer to how long does epoxy pipe lining last is often "longer than the original pipe itself."

Is Epoxy Lining Cost-Effective for Large Projects?

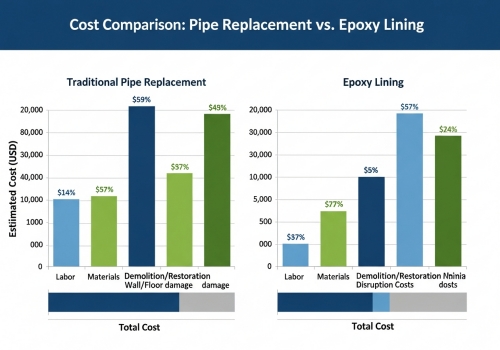

Budget overruns are a procurement manager's worst enemy. You need to justify every cent spent to your stakeholders, so let's analyze the real Return on Investment (ROI) of this technology. Yes, it is highly cost-effective. While initial material costs exist, you save up to 40% by eliminating excavation, reducing labor hours, and minimizing downtime. The long lifespan means fewer replacements over time.

When you look at the price tag of epoxy resin, it might seem high per liter. However, you must look at the Total Cost of Ownership (TCO). In the construction industry, labor and restoration usually consume the biggest part of the budget. If you choose traditional replacement, you have to bring in heavy excavators, dig up trenches (destroying roads, floors, or landscapes), remove the old steel, install the new steel, and then backfill and re-pave the area. With epoxy lining, you skip almost all of those steps. You only need small access points. For a factory or an oil refinery, this also means operational continuity. You don't have to shut down the whole plant for weeks; lining can often be done in 24 to 48 hours. Time is money, especially in EPC contracts where delays result in penalties. Let's compare the costs directly:

| Cost Category | Traditional Replacement | Epoxy Lining |

|---|---|---|

| Excavation | High Cost | Near Zero |

| Material | Medium (New Steel) | Medium (Resin + Liner) |

| Labor Time | Weeks | Days |

| Site Restoration | High Cost | None |

| Life Expectancy | 20-40 Years (if uncoated) | 50+ Years |

From my experience supplying global projects, the savings on "hidden costs" (like traffic permits or business downtime) often make epoxy lining the only logical choice for rehabilitation. It solves the problem of how long does epoxy pipe lining last by providing a solution that outlives the investment period.

Conclusion

Epoxy lining is a durable, cost-effective solution that prevents corrosion and leaks for over 50 years. It saves time, money, and protects the environment.

One More Thing: Finego Steel Solutions

While lining is excellent for repairing old pipes, if you are planning a new project, you should start with the best protection immediately. At Finego Steel, we provide high-quality Epoxy Coated Pipes (3PE, FBE) directly from our factory. Don't wait for your pipes to corrode before acting. By choosing our factory-coated steel pipes for your initial installation, you guarantee that 50-100 year lifespan from day one. We serve EPC companies globally with heavy-thickness, large-diameter pipes perfect for oil, gas, and construction. Let us help you build it right the first time.

Language

Language