- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Is BS 1387 Galvanized Steel Pipe Still the Right Solution for Industrial Piping?

Finding reliable piping for water and gas projects is stressful when quality varies across suppliers. Poor materials cause leaks, project delays, and safety hazards that ruin your reputation. You need a standard that guarantees safety and durability for your specific engineering needs. BS 1387 galvanized steel pipe is a welded or seamless tube coated in zinc, specifically designed for gas, air, and water transport. Although European standards like EN 10255 have appeared, this standard remains vital for low-pressure systems requiring threaded connections and high corrosion resistance.

I have worked in the steel industry for a long time, and I know that choosing the right pipe is about more than just the price. It is about sleeping well at night knowing the pipes will not leak. In the next sections, I will break down everything you need to know about this standard so you can make the best choice for your company.

What defines the specifications and grades of this pipe standard?

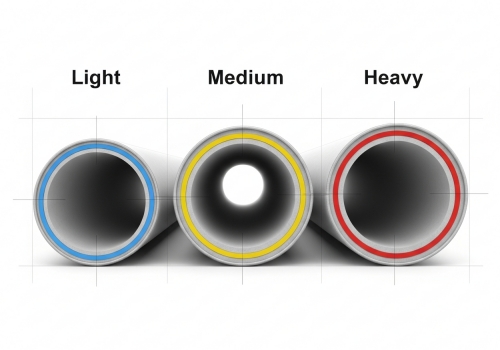

Confusing wall thicknesses can lead to buying the wrong pipe for your pressure needs. This mistake wastes your budget and endangers your project integrity. Understanding the specific classes of this standard solves that problem immediately. The standard categorizes pipes into three specific classes based on wall thickness: Light, Medium, and Heavy. Each class serves a different pressure requirement, ensuring you only pay for the material strength your specific project actually needs.

I talk to many engineers and purchasing managers who get confused by the different grades available in the market. Let me make it simple for you. The bs 1387 galvanized steel pipe comes in three distinct weights. We call them Light, Medium, and Heavy. In my experience at Finego Steel, the Medium class is what most people buy for standard water and gas lines. It offers a good balance. But if you are building something that needs to last a very long time or takes a lot of physical hits, you must go with Heavy. To help you check the quality when the goods arrive at your site, you should look for specific color bands painted on the pipes. This is a quick way to know what you have without using a caliper on every single pipe. It saves your inspection team a lot of time.

| Class | Wall Thickness Description | Identification Color | Typical Application |

|---|---|---|---|

| Light | Thinner walls | Brown | Low-pressure domestic water, decorative use |

| Medium | Standard thickness | Blue | General industrial water lines, gas distribution, air lines |

| Heavy | Thickest walls | Red | High-pressure steam, heavy industrial use, structural support |

How does the hot-dip galvanizing process ensure long-term quality?

Rust is the enemy of any steel project and destroys your reputation with clients. Replacing corroded pipes is expensive and disrupts operations. You need a manufacturing process that stops rust before it starts. The hot-dip process involves submerging the clean steel pipe into molten zinc at roughly 450°C. This creates a metallurgical bond between the zinc and the steel, providing a sacrificial layer that corrodes in place of the iron to prevent structural failure.

You might wonder why we still use hot-dip galvanizing when there are paints and other coatings available today. The answer is in the chemistry. When we make bs 1387 galvanized steel pipe, we do not just paint it. We dip the steel into a bath of liquid zinc that is very hot. It is about 450°C. This is not just a coating that sits on top like a sticker. The zinc actually bites into the steel. It forms an alloy layer that is part of the pipe itself. This matters because of scratches. On a busy construction site, pipes get dragged and banged around. If you scratch normal paint, the steel underneath rusts immediately. But with hot-dip galvanizing, the zinc acts like a bodyguard. It sacrifices itself. The zinc will rust first, saving the steel pipe underneath. This is why these pipes last so long outdoors, even in bad weather. At Finego Steel, we take testing seriously. The standard requires a hydrostatic test. We fill the pipe with water under pressure to make sure there are no leaks. We also do flattening tests. We squash the pipe to see if the weld cracks. If it cracks, we reject it immediately. We do this so you do not face failures after installation. We know that for an EPC company, one bad pipe can ruin a whole system. We want to be the partner that saves you from that trouble.

What are the best applications and trade-offs for this material?

Choosing the wrong material for the environment leads to early system failure. Plastic is cheap but weak against fire and impact. You need to know exactly where steel performs best to save costs effectively. These pipes are ideal for fire sprinkler systems, outdoor gas lines, and scaffolding due to their high mechanical strength and fire resistance. While heavier than plastic options, they withstand physical impact and high temperatures far better than PVC or PPR. I have been in this industry since 1996, and I have seen the rise of plastic pipes in the market. Yes, plastic is light and cheap. But steel is still king for many tough jobs. You should use bs 1387 galvanized steel pipe when strength is the main priority. Think about a fire sprinkler system. If there is a fire, plastic might melt and fail. Steel will not. That keeps the water flowing when you need it most to save lives and property. Also, think about gas. A gas leak is dangerous. You want a pipe that will not break if someone accidentally hits it with a heavy tool or a forklift. Steel is tough. It takes a hit and stays intact. However, I will be honest with you. There are downsides. Steel is heavy. Your workers will get tired faster moving these pipes compared to plastic. The internal wall is also not as smooth as plastic, which can slow down water flow slightly over many years. And the cost is higher. But you are paying for safety and a long life. Here is a quick breakdown of where we see our clients using these pipes:

· HVAC: Compressed air lines in factories.

· Construction: Scaffolding and fence posts.

Utilities: Low-pressure gas and water mains. At Finego Steel, we supply these to big companies like CNPC and Shell because they value that strength. We act as a one-stop supplier to help you mix these steel pipes with the fittings and valves you need. This saves you time sourcing from different places.

Conclusion

BS 1387 pipes provide essential strength and safety for critical infrastructure. At Finego Steel, we deliver high-quality, tested pipes to help you build durable projects efficiently and cost-effectively.

Language

Language