- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What Are the Different Types of Oil and Gas Pipe Fittings You Need to Know?

Sourcing the right components for a massive pipeline project can feel like a high-stakes puzzle. One wrong part can lead to leaks, project delays, and massive financial losses for your company. Oil and gas pipe fittings are specialized components, such as elbows, tees, and reducers, designed to connect pipes, change direction, and regulate flow. They are manufactured from robust materials like carbon steel and stainless steel to withstand the extreme pressure and corrosive environments typical in energy infrastructure.

You need to understand these components to make smart buying decisions. We will look at the specific types and materials that keep pipelines safe.

Which Specific Designs of Oil and Gas Pipe Fittings Are Essential for Your Project?

Mismatched specifications on a construction site can stop work immediately. Are you struggling to categorize the vast array of components needed for your piping lists? The most critical fittings include elbows for changing direction, tees for splitting fluid flow, and reducers for connecting pipes of different sizes. High-pressure systems also rely on heavy-duty couplings and unions to ensure a leak-proof seal while allowing for future maintenance.

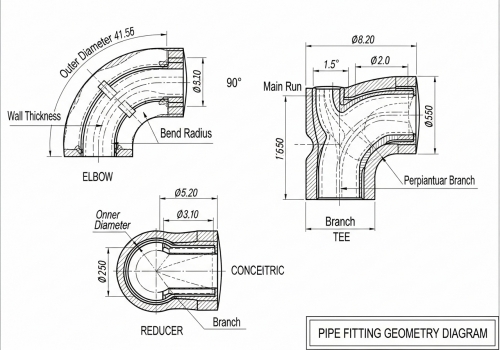

In my experience at Finego Steel, I see many purchasing managers overwhelmed by the sheer variety of items on a Bill of Materials. We need to break these down into their core functions. This helps you order the correct oil and gas pipe fittings for your specific engineering requirements. Elbows: Controlling Direction These are the most common fittings you will encounter. They serve a simple purpose: changing the direction of the flow. You will mostly see 90-degree and 45-degree elbows. However, it goes deeper than just the angle. There are "long radius" elbows (1.5 times the pipe diameter) which create less friction and smoother flow, and "short radius" elbows (equal to the pipe diameter) for tight spaces where clearance is an issue. Using the wrong radius can mess up flow dynamics in high-speed lines. Tees and Crosses: Managing Flow Distribution When you need to distribute oil or gas to different lines, you use a Tee. It has one inlet and two outlets forming a "T" shape. If the outlets are the same size, it is an "Equal Tee." If the branch is smaller than the main run, it is a "Reducing Tee." Crosses are similar but have four openings; these are less common in main transmission lines but often used in fire sprinkler systems or complex distribution headers. Reducers: Adapting Pipe Sizes These connect big pipes to small pipes. There are two main types you must distinguish between:

· Eccentric Reducers: These are flat on one side. They are absolutely critical in horizontal lines, especially on the suction side of pumps. The flat side prevents air bubbles (cavitation) from getting trapped at the top of the pipe, which could damage the pump. Caps and Plugs: Sealing the System You use these to stop the flow at the end of a line. While they seem simple, they must withstand the full line pressure. This is vital for safety during maintenance or for closing off lines intended for future expansion. At Finego Steel, we ensure all these fittings meet international standards like ASME B16.9 and ASTM regulations. We know that a simple Elbow failure due to poor wall thickness can shut down an entire processing plant.

How Does Material Selection Impact the Longevity of Pipeline Systems?

Corrosion is the silent killer of expensive infrastructure projects. Choosing the wrong alloy for your environment guarantees premature failure and safety hazards for your client. Material selection depends on the fluid composition, temperature, and pressure of the system. Carbon steel is the standard for general transport, while stainless steel and specialized alloys are vital for resisting corrosion in harsh, sour service environments.

The material is just as important as the shape of the fitting. As a supplier since 1996, I have seen pipelines fail simply because the material did not match the environment. You must choose materials that can handle the stress, not just the cheapest option. Carbon Steel (The Industry Standard) This is the workhorse of the industry. It is strong, durable, and handles high pressure well. We see this used in most long-distance transmission lines. Common grades include ASTM A234 WPB. It is cost-effective but can rust if not coated properly. It is generally not suitable for extremely low temperatures or highly corrosive fluids. Stainless Steel (The Corrosion Fighter) When the fluid contains moisture, CO2, or the temperature is very high, you need stainless steel. It contains chromium, which creates a passive layer to stop rust. Grades like 304 and 316 are standard. This is expensive but necessary for offshore rigs or chemical processing areas where replacing pipes is difficult and costly. Alloy Steel (High Performance) This is steel mixed with other elements like molybdenum, chromium, or nickel. It is lighter and stronger than standard carbon steel. We recommend this for high-stress lines or high-temperature power generation applications. Non-Metallic Options For low-pressure lines, like water drainage or some gas distribution networks, you might use PE (Polyethylene) or PVC. These do not corrode, but they cannot handle the high pressure or heat of a main oil line. Here is a quick reference guide I use to help clients decide:

| Material | Common Grade | Key Characteristic | Best Use Case |

|---|---|---|---|

| Carbon Steel | ASTM A234 WPB | High Strength, Low Cost | General Oil & Gas Transport |

| Stainless Steel | ASTM A403 WP304/316 | Corrosion Resistance | Sour Gas, Chemical Injection |

| Alloy Steel | ASTM A234 WP11/WP22 | Heat & Pressure Resistance | Power Plants, High-Temp Lines |

| Low Temp Steel | ASTM A420 WPL6 | Impact Toughness | Cryogenic / Arctic Pipelines |

| Duplex Steel | ASTM A815 | Extreme Strength | Deepwater Offshore Pipelines |

We provide oil and gas pipe fittings in all these materials. We can also provide mill test certificates to prove the chemical composition and mechanical properties of every piece.

What Are the Best Connection Methods for High-Pressure Systems?

A seam failure under extreme pressure is a nightmare scenario for any engineer. Do you know if your supplier is providing the correct connection types for your critical pressure lines? For high-pressure oil and gas pipe fittings, Butt Weld (BW) connections are preferred as they create a permanent, leak-proof bond. For smaller bore pipes, Socket Weld (SW) or Threaded connections are used, though threaded connections are generally limited to lower pressure applications. The way you connect the fitting to the pipe dictates the strength of the whole system. In my 18 years of experience working with engineers, I have learned that the connection method is often where leaks happen, not the pipe itself. Butt Weld (BW) This is the strongest connection type. The end of the fitting is beveled (sloped). It is placed against a matching beveled pipe and welded all the way around.

· Pros: It uses less material, allows for full X-ray inspection, and offers the best flow dynamics because the inside is smooth.

· Cons: It requires skilled welders and takes time. It is standard for critical lines in refineries and cross-country pipelines (2 inches and larger). Socket Weld (SW) You use this for smaller pipes (usually under 2 inches). The pipe slides into a recessed socket in the fitting. Then, you weld the outside fillet.

· Pros: It is easier to align than a butt weld.

· Cons: It leaves a small gap inside where fluid can get trapped. This can cause corrosion or issues in food/pharmaceutical lines (though less of an issue in crude oil). Threaded Fittings (NPT/BSP) These screw onto the pipe. They are quick to install and need no welding.

· Pros: Great for maintenance areas where welding is dangerous (no open flame).

· Cons: High vibration can loosen threads over time. They are the weakest link in high-pressure systems. We suggest these only for non-critical, low-pressure instrument lines. Seamless vs. Welded Manufacturing You also need to look at how the fitting itself is made, which often mirrors the pipe type:

· Seamless: Made from a solid piece of steel. No weak points. Best for high pressure.

· Welded (ERW/LSAW/SSAW): Made from rolling a plate and welding the seam. These are cheaper and good for large diameters. However, if you use a welded fitting on a seamless pipe project, your client might reject it. At Finego Steel, we help you choose the right connection. We inspect the bevels and threads before shipping to ensure your installation team has no issues on site.

Conclusion

You must select the right shapes, materials, and connection types to build a safe pipeline. We at Finego Steel are ready to be your one-stop partner for these critical components.

Language

Language