- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

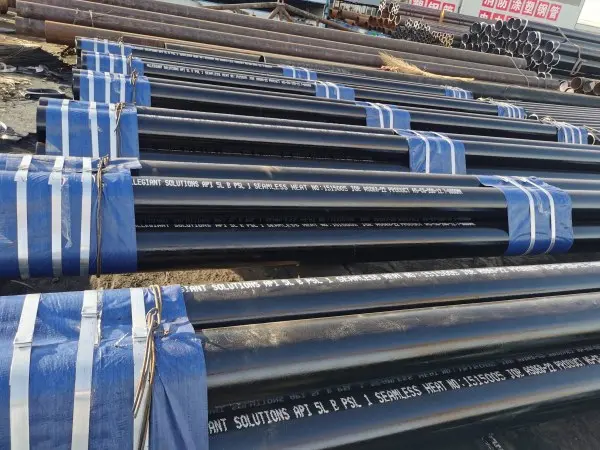

Seamless Steel Pipe

Hot Rolled Steel Pipe

Process: Seamless Steel Pipe (SMLS Steel Pipe)

Usage: Applicable to the general structure, mechanical structure, water wall panel, economizer, super heater, boiler and heat exchanger with seamless steel tubes, and to transport liquid, gas, oil etc.

Standard: API 5L, API 5CT, ASTM A106/A53, ASTM A519, JIS G 3441, JIS G3444, JIS G3445 DIN 2391, EN10305, EN10210, ASME SA106, SA192, SA210, SA213, SA335, DIN17175, ASTM A179…

Out Diameter: 1/8 – 36inch (10.3-914.4mm)

Wall Thickness: 1.73-40mm

Length: Random Length, Fixed Length, SRL, DRL

Standard

- API Spec 5L

- ASTM A53/A53M

- ASTM A106/A106M

- ASTM A135/A135M

- ASTM A178/A178M

- ASTM A179/A179M

- ASTM A192/A192M

- ASTM A209/A209M

- ASTM A210/A210M

- ASTM A213/A213M

- ASTM A312/A312M

- ASTM A333/A333M

- ASTM A335/A335M

- ASME SA106/SA106M

- ASME SA135/SA135M

- ASME SA178/SA178M

- ASME SA179/SA179M

- ASME SA192/SA192M

- ASME SA209/SA209M

- ASME SA210/SA210M

- ASME SA213/SA213M

- ASME SA312/SA312M

- ASME SA333/SA333M

- ASME SA335/SA335M

- BS 1387

- BS 3059

- DIN 1629

- DIN 2391

- DIN 30670

- EN 1092

- EN 10204

- EN 10210

- EN 10216-2

- EN 10217

- EN 10219

- EN 10296

- EN 10297

- EN 10312

- JIS G3441

- JIS G3444

- JIS G3445

- JIS G3452

- JIS G3454

- JIS G3456

- JIS G3457

- JIS G3461

- JIS G3462

Specification

Hot-rolled seamless steel pipe is a large category of seamless steel pipe, which is divided according to the production method. Hot rolling is relative to cold rolling, cold rolling is carried out rolling at room temperature, and hot rolling is carried out rolling at the recrystallization temperature. Seamless steel pipe is named relative to the welded steel pipe, seamless steel pipe is usually made of round steel perforation and reprocessing, welding steel pipe is usually welded by steel plate in different ways. The diameter of hot-rolled seamless steel pipe is usually above 38mm. Steel pipe with smaller diameter can be obtained by cold rolling or cold drawing.

Hot-rolled seamless steel pipe is manufactured by hot rolling technology, as the name suggests, the temperature of rolled piece is high, so the deformation resistance is small to achieve large deformation. Take rolling of steel plate for example, the general thickness of continuous casting slab is about 230mm, and after roughing mill and finishing mill, the final thickness is 1~20mm. At the same time, due to the small thickness ratio of steel plate, the dimension accuracy is relatively low, it’s not easy to cause shape problem.

Application & Specification:

|

Oil & Gas Sector |

|

|

API |

5L |

|

API |

5CT |

|

IS |

1978, 1979 |

|

Automotive Industry |

|

|

ASTM |

A-519 |

|

SAE |

1010, 1012, 1020, 1040, 1518, 4130 |

|

DIN |

2391, 1629 |

|

BS |

980, 6323 (Pt-V) |

|

IS |

3601, 3074 |

|

Hydrocarbon Process Industry |

|

|

ASTM |

A-53, A-106, A-333, A-334, A-335, A-519 |

|

BS |

3602,3603 |

|

IS |

6286 |

|

Bearing Industry |

|

|

SAE |

52100 |

|

Hydraulic Cylinder |

|

|

SAE |

1026, 1518 |

|

IS |

6631 |

|

DIN |

1629 |

|

Boiler, Heat Exchanger, Superheater & Condenser |

|

|

ASTM |

A-179, A-192, A-209, A-210, A-213, A-333, A-334,A-556 |

|

BS |

3059 (Pt-I Pt-II) |

|

IS |

1914, 2416, 11714 |

|

DIN |

17175 |

|

Railways |

|

|

IS |

1239 (Pt-I),1161 |

|

BS |

980 |

|

Mechanical, Structural General Engineering |

|

|

ASTM |

A-252, A-268, A-269, A-500, A-501, A-519, A-589 |

|

DIN |

1629, 2391 |

|

BS |

806, 1775, 3601, 6323 |

|

IS |

1161, 3601 |

Advantages:

It can destroy the microstructure of ingot casting, grain refinement of steel and eliminate microstructure defects, so that make steel structure compact and improve the mechanical properties. This improvement is mainly reflected in the rolling direction, so that the steel no longer is isotropic; Formation of bubbles, cracks and loose when pouring can also be welded under high temperature and pressure.

Process

Round Bars → Heating → Piercing → Three-Roll Cross Rolling, Rolling Or Extrusion → Detached → Sizing (Or Reducing) → Cooling → Parison Tube → Straightening → Hydrostatic Test (Or Flaw Detection) → Mark → Storage

Language

Language