- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

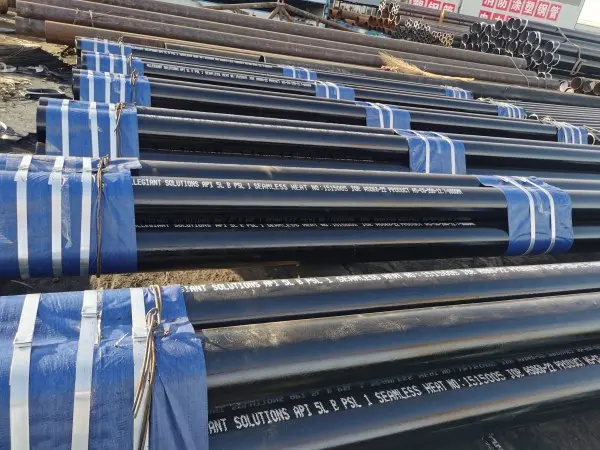

Seamless Steel Pipe

Cold Rolled Steel Pipe

Out Diameter: 19.05-114.3mm

Wall Thickness: 2-14mm

Length: 3m-10m.

Standard & Grade: ASTM A53, ASTM A106, API5l, DIN 1629, DIN 17175, BS, JIS, GB. Grade: gr.b, st35, st37, st42, st35.8-st45.8, x42, x52, x60.

Surface: Black oil coating, galvanized coating, pe

Packing: Bundle or bulk , seaworthy packing or for the client's requirement

Usage: For conveying gas, water and oil either in the oil or natural gas industries

Standard

- API Spec 5L

- ASTM A53/A53M

- ASTM A106/A106M

- ASTM A135/A135M

- ASTM A178/A178M

- ASTM A179/A179M

- ASTM A192/A192M

- ASTM A209/A209M

- ASTM A210/A210M

- ASTM A213/A213M

- ASTM A312/A312M

- ASTM A333/A333M

- ASTM A335/A335M

- ASME SA106/SA106M

- ASME SA135/SA135M

- ASME SA178/SA178M

- ASME SA179/SA179M

- ASME SA192/SA192M

- ASME SA209/SA209M

- ASME SA210/SA210M

- ASME SA213/SA213M

- ASME SA312/SA312M

- ASME SA333/SA333M

- ASME SA335/SA335M

- BS 1387

- BS 3059

- DIN 1629

- DIN 2391

- DIN 30670

- EN 1092

- EN 10204

- EN 10210

- EN 10216-2

- EN 10217

- EN 10219

- EN 10296

- EN 10297

- EN 10312

- JIS G3441

- JIS G3444

- JIS G3445

- JIS G3452

- JIS G3454

- JIS G3456

- JIS G3457

- JIS G3461

- JIS G3462

Specification

In the industrial piping industry, cold rolled steel tubes are often seen as a premium option, especially in those applications where high precision and excellent mechanical properties are required. The steel cold rolling process not only improves the dimensional stability of the tubes, but also enhances their mechanical properties, such as tensile strength and fatigue resistance.

Cold rolled steel tubes are produced by further processing of the billet. During the cold rolling process, the tube undergoes several rolling steps in a controlled environment to improve its accuracy, finish and mechanical properties. This process takes place at lower temperatures, hence the name "cold" rolling. Without the involvement of high-temperature heat treatment, cold rolled tubes typically have a finer grain structure, which helps improve their mechanical properties and corrosion resistance.

Industry Specifications for Seamless Pipes:

Since ASTM A513 covers the specifications for mechanical tubing made from cold-rolled steel, it forms the basis of many production processes.

|

ASTM A513 Properties |

Details |

|

Range of Pipes |

These standards cover carbon steel grades 1008 and above, including grades 1021, 1026, 1524, 4130, and 4140. |

|

Testing requirements |

Tensile, elongation, and yield testing aren't required under A513 specifications unless specifically requested. |

|

Uses |

These requirements are well suited for electrical welded and alloy steel tubings and get mostly used by the automobile and mechanical industry. |

General Features Of Cold Rolled Pipes:

Cold rolling is used to produce round or specially shaped pipes. Cold-rolled pipes have a lower diameter than hot-rolled pipes, with a maximum outer diameter of 6 mm.

Pipes made via this rolling method have thin walls up to 0.25 mm thick.

Temperatures for cold rolling should be well under 1652 Degrees Fahrenheit and typically limited to room temperature.

Cold-rolled pipes possess greater dimensional accuracy than hot-rolled ones.

Since they go through extensive shaping operations, cold-rolled pipes are harder and have a smoother surface area.

Chemical Requirements:

|

|

|

|

|

|

|

|

Element |

Manganese |

Phosphorous |

Iron |

Carbon |

Sulphur |

|

Maximum Percentage |

0.6 % |

0.04 % |

99.53 % |

0.23 % |

0.05 % |

Important Physical Properties:

Yield Strength: 511.59 mpa

Max. Tensile Strength: 910.10 mpa

Max. Elongation: 22 %

Temperature: Below 1652 Degrees Fahrenheit

Density: 0.28 Lb/in3

Advantages Of Cold Rolled Pipes:

Consistent thickness, smooth aesthetic finish- home appliances, metal furniture, construction materials. The reason manufacturers choose to cold roll their pipes is because it increases the marketability of the product.

Among other advantages, not only is cold-rolled pipes stronger than hot-rolled pipes, but they are also more bendable. Their other characteristics include.

Cold rolling increases the strength of the pipe, with a 20% increase in hardness.

Cold-rolled pipes have a higher tolerance despite being smaller and thinner than hot-rolled pipes.

To produce cold-rolled pipes, steel billets get passed through several rollers. This equipment squeezes and compresses the metal, helping increase the durability and yield strength of the product.

In cold rolling, pipes are processed further after the exposure to the heat, helping them maintain a consistent uniformity.

Cold-rolled tubes contain lesser amounts of carbon than hot-rolled ones. This quality makes it smoother, more consistent, and easier to process for blacksmiths.\

Cold rolled steel tubing has an improved surface finish, boosting its aesthetic appeal.

Cold rolling improves dimensional accuracy, leading to better product precision and concentricity.

Cold-rolled pipes have more mechanical properties than hot-rolled ones, increasing their value.

Application Of Cold Rolled Pipes:

Cold rolled pipes have a high aesthetic finish, with a smooth surface finish and well-proportioned dimensions. In addition, they are harder while being easier to shape than hot-rolled pipes. For these reasons, cold-rolled pipes have applications in things like;

Cold-pressed pipes can be used in metal furniture, including desks, filing cabinets, tables, chairs,

They even get used motorcycle and car exhaust pipes in the automobile industry.

Cold-pressed pipes can be used to make computer cabinets and home appliances as shelving, lighting fixtures, and more.

The high aesthetic value of cold-rolled pipes makes them a valuable construction material for projects focusing on visual appeal.

Process

Round Tube Billet→Heating→Piercing→Heading→Annealing→Pickling→Oiling (Copper Plating)→Multi-Pass Cold Drawing (Cold Rolling)→Billet Tube→Heat Treatment→Straightening→Hydraulic Test (Flaw Detection)→Mark→Warehousing

Language

Language