- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Seamless Steel Pipe

Cold Drawn Steel Pipe

A cold-drawn pipe is tubing drawn cold through steel or carbide die to elongate and improve its dimensional accuracy. The cold drawing process may or may not have a mandrel or a floating plug inserted inside the tube to help enhance the wall thickness.

Cold drawing costs more than hot rolling as the manufacturing process involves more labor, time, and energy. However, the result of this process is also superior, with the cold drawn steel pipe revealing a better surface finish and more even concentricity.

Standard

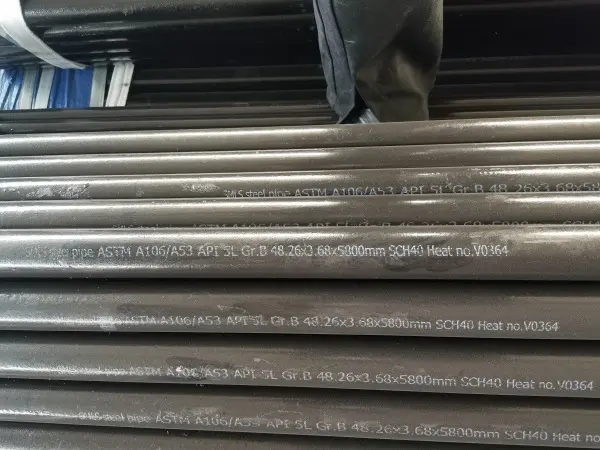

- API Spec 5L

- ASTM A53/A53M

- ASTM A106/A106M

- ASTM A135/A135M

- ASTM A178/A178M

- ASTM A179/A179M

- ASTM A192/A192M

- ASTM A209/A209M

- ASTM A210/A210M

- ASTM A213/A213M

- ASME SA53/SA53M

- ASME SA106/SA106M

- ASME SA135/SA135M

- ASME SA178/SA178M

- ASME SA179/SA179M

- ASME SA192/SA192M

- ASME SA209/SA209M

- ASME SA210/SA210M

- ASME SA213/SA213M

- ASME SA312/SA312M

- BS 1387

- DIN 30670

- EN 10210

- EN 10216-2

- EN 10217

- EN 10219

- EN 10296

- EN 10297

- EN 10312

- JIS G3441

- JIS G3444

- JIS G3445

- JIS G3452

- JIS G3454

- JIS G3456

- JIS G3457

- JIS G3461

- JIS G3462

Specification

Characteristics:

Cold Drawn Pipes are usually in small diameter sizes and are commonly quoted to fit lower than average specifications.

These pipes often get used where dimensional tolerances are tighter than average.

Cold drawing is sometimes considered to be part of cold rolling.

The starting stock in the cold drawing is usually a hot rolled tube

Cold-drawn pipes get pulled over a die, with or without a mandrel.

Advantages:

When it comes to cold drawing, the stock tube is drawn at room temperature, which leads to a high degree of microstructural consistency and unity.

Cold-drawn pipes are exposed to high pressure as they get drawn through dies for elongation. This pressure leads to higher tensile strength in these products.

Unlike hot rolling, the tubing must get drawn multiple times to make a cold finished product. This process allows producers to make pipes with close dimensional tolerances and even thickness and diameter.

Drawing the stock at lower temperatures gives the tubes a high strength-to-weight ratio improving their safety and application potential.

Using the die and the mandrel in cold rolling improves the outside and the inside diameter surface quality.

Cold drawing improves the machinability of the hot rolled steel tube, widening its range of applications.

Hot rolled pipes get pickled to remove the surface contaminants, mill scales, and iron oxides. This process enhances the pipe's aesthetic appeal, giving it a glossier, even surface finish.

Application:

Industrial machinery: in tool extensions, machine components, frames, hydraulics, and more.

Automobile industry; as fenders, axels, car seating frames, chassis components, roll cages, shaft tubes, and more.

Furniture making: as frames for benches, beds, desks, chairs, displays, fixtures, and more.

Oil and energy: as bearings, turbine parts, pumps, columns, rolls, and more.

In artwork, installations, and more.

Specification:

|

Cold Drawn Seamless Tube – Mechanical – BS 6323 Part 4 : 1982 CFS 3 |

|||||||||||||||||||

|

BS 6323 Part 4 : 1982 Bright-as-Drawn – CFS 3 BK Annealed – CFS 3 GBK |

|||||||||||||||||||

|

|

Wall |

0.71 |

0.81 |

0.91 |

1.22 |

1.42 |

1.63 |

2.03 |

2.34 |

2.64 |

2.95 |

3.25 |

4.06 |

4.76 |

4.88 |

6.35 |

7.94 |

9.53 |

12.70 |

|

O.D. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.76 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.35 |

|

|

|

X |

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

7.94 |

|

|

|

X |

X |

|

X |

X |

|

|

|

|

|

|

|

|

|

|

|

|

9.53 |

|

|

|

X |

X |

X |

X |

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

11.11 |

|

|

|

X |

X |

X |

X |

X |

|

|

|

|

|

|

|

|

|

|

|

|

12.70 |

|

|

|

X |

X |

X |

X |

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

14.29 |

|

X |

|

X |

X |

|

X |

X |

|

X |

X |

X |

|

|

|

|

|

|

|

|

15.88 |

|

|

|

X |

X |

|

X |

X |

|

X |

X |

X |

X |

|

X |

|

|

|

|

|

17.46 |

|

|

|

X |

|

|

X |

X |

|

|

|

X |

|

|

|

|

|

|

|

|

19.05 |

|

|

|

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

X |

X |

|

|

|

|

20.64 |

|

|

|

|

|

|

X |

X |

|

|

|

X |

|

|

|

|

|

|

|

|

22.22 |

|

|

|

|

X |

X |

X |

X |

|

X |

X |

X |

X |

|

X |

X |

|

|

|

|

25.40 |

|

|

|

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

X |

X |

|

|

|

|

26.99 |

|

|

|

|

|

|

X |

X |

|

|

|

X |

X |

|

X |

|

|

|

|

|

28.58 |

|

|

|

|

X |

X |

X |

X |

|

X |

|

X |

X |

|

X |

X |

|

|

|

|

30.16 |

|

|

|

|

|

|

X |

X |

|

X |

|

|

|

|

|

|

|

|

|

|

31.75 |

|

|

|

|

X |

|

X |

X |

|

X |

|

X |

X |

|

X |

X |

X |

|

|

|

33.34 |

|

|

|

|

|

|

X |

|

|

|

|

X |

|

|

|

|

|

|

|

|

34.93 |

|

|

|

|

X |

|

X |

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

|

38.10 |

|

|

|

|

|

|

X |

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

|

39.69 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

|

|

|

|

|

41.28 |

|

|

|

|

|

|

X |

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

|

42.86 |

|

|

|

|

|

|

|

|

|

X |

|

X |

|

|

|

|

|

|

|

|

44.45 |

|

|

|

|

|

|

X |

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

|

47.63 |

|

|

|

|

|

|

|

|

|

X |

|

X |

X |

|

X |

X |

X |

|

|

|

50.80 |

|

|

|

|

X |

|

X |

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

|

53.98 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

X |

X |

X |

|

|

57.15 |

|

|

|

|

|

|

|

X |

|

X |

|

X |

X |

|

X |

X |

|

X |

|

|

60.33 |

|

|

|

|

|

|

X |

|

|

|

|

X |

X |

|

X |

X |

X |

X |

|

|

63.50 |

|

|

|

|

|

|

|

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

|

|

66.68 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

X |

|

|

|

|

69.85 |

|

|

|

|

|

|

|

|

|

X |

|

X |

X |

|

X |

X |

|

X |

X |

|

73.02 |

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

76.20 |

|

|

|

|

|

|

X |

X |

|

X |

|

X |

|

|

X |

X |

X |

X |

X |

|

79.38 |

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

82.55 |

|

|

|

|

|

|

X |

|

|

X |

|

X |

|

|

|

X |

|

X |

|

|

88.90 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

X |

X |

X |

|

|

95.25 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

X |

|

|

|

|

101.60 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

|

|

|

|

|

107.95 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

X |

|

|

|

|

114.30 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

X |

|

|

|

|

127.00 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

X |

|

|

Cold Drawn Seamless Tube – Mechanical |

||||||||||||||||||

|

Cold Drawn Seamless tube for Hydraulic & Pneumatic Lines – BS 3602 Part 1 CFS Cat 2 Alternatively Din 2391 ST 35.4 NBK |

||||||||||||||||||||

|

BS 3602 Part 1 CFS Cat 2 Alternatively Din 2391 ST 35.4 NBK |

||||||||||||||||||||

|

|

Wall |

0.91 |

1.00 |

1.22 |

1.42 |

1.50 |

1.63 |

2.00 |

2.03 |

2.50 |

2.64 |

2.95 |

3.00 |

3.25 |

3.66 |

4.00 |

4.06 |

4.88 |

5.00 |

6.00 |

|

O.D. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6.00 |

|

|

X |

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

6.35 |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.94 |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.00 |

|

|

X |

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

9.52 |

|

X |

|

X |

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

10.00 |

|

|

X |

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

12.00 |

|

|

X |

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

|

12.70 |

|

X |

|

X |

|

|

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

13.50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

14.00 |

|

|

X |

|

|

X |

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

15.00 |

|

|

X |

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

|

15.88 |

|

X |

|

X |

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

16.00 |

|

|

X |

|

|

X |

|

X |

|

|

|

|

X |

|

|

|

|

|

|

|

|

17.46 |

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

18.00 |

|

|

X |

|

|

X |

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

|

19.05 |

|

|

|

X |

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

20.00 |

|

|

|

|

|

X |

|

X |

|

X |

|

|

X |

|

|

X |

|

|

|

|

|

21.43 |

|

|

|

|

|

|

|

|

|

|

X |

|

|

X |

|

|

|

|

|

|

|

22.00 |

|

|

|

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

|

22.22 |

|

|

|

X |

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

25.00 |

|

|

|

|

|

X |

|

X |

|

X |

|

|

X |

|

|

X |

|

|

|

|

|

25.40 |

|

|

|

X |

|

|

X |

|

X |

|

X |

|

|

X |

|

|

|

|

|

|

|

26.99 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

28.00 |

|

|

|

|

|

x |

|

x |

|

x |

|

|

|

|

|

X |

|

|

|

|

|

30.00 |

|

|

|

|

|

|

|

X |

|

X |

|

|

X |

|

|

X |

|

|

X |

|

|

31.75 |

|

|

|

|

|

|

X |

|

X |

|

X |

|

|

X |

|

|

X |

|

|

|

|

34.13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

34.93 |

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

|

35.00 |

|

|

|

|

|

X |

|

X |

|

|

|

|

X |

|

|

X |

|

|

|

|

|

38.00 |

|

|

|

|

|

|

|

X |

|

|

|

|

X |

|

|

X |

|

|

X |

X |

|

38.10 |

|

|

|

|

|

|

X |

|

|

|

X |

|

|

X |

|

|

|

|

|

|

|

42.00 |

|

|

|

|

|

|

|

X |

|

|

|

|

X |

|

|

|

|

|

|

|

|

44.45 |

|

|

|

|

|

|

X |

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

48.42 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

50.00 |

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

50.80 |

|

|

|

|

|

|

X |

|

X |

|

|

X |

|

|

X |

|

|

X |

|

|

|

|

Cold Drawn Seamless tube for Hydraulic & Pneumatic Lines |

|||||||||||||||||||

Standard:

|

Oil &Gas |

|

|

API |

5L |

|

API |

5CT |

|

IS |

1978, 1979 |

|

Automotive Industry |

|

|

ASTM |

A-519 |

|

SAE |

1010, 1012, 1020, 1040, 1518, 4130 |

|

DIN |

2391, 1629 |

|

BS |

980, 6323 (Pt-V) |

|

IS |

3601, 3074 |

|

Hydrocarbon Process Industry |

|

|

ASTM |

A-53, A-106, A-333, A-334, A-335, A-519 |

|

BS |

3602,3603 |

|

IS |

6286 |

|

Bearing Industry |

|

|

SAE |

52100 |

|

Hydraulic Cylinder |

|

|

SAE |

1026, 1518 |

|

IS |

6631 |

|

DIN |

1629 |

|

Boiler, Heat Exchanger, Superheater & Condenser |

|

|

ASTM |

A-179, A-192, A-209, A-210, A-213, A-333, A-334,A-556 |

|

BS |

3059 (Pt-I Pt-II) |

|

IS |

1914, 2416, 11714 |

|

DIN |

17175 |

|

Railways |

|

|

IS |

1239 (Pt-I),1161 |

|

BS |

980 |

|

Mechanical, Structural General Engineering |

|

|

ASTM |

A-252, A-268, A-269, A-500, A-501, A-519, A-589 |

|

DIN |

1629, 2391 |

|

BS |

806, 1775, 3601, 6323 |

|

IS |

1161, 3601 |

Process

Once lubed, the tubing is ready to be cold-drawn.

Once the tubing enters the opening, a drawing machine begins slowly pulling the pipe forward while the die exerts pressure from all sides.

Room temp is the typical temperature for this process, and the steel tube is extruded at one end before the insertion because the die diameter is smaller than the hot-finished pipe.

This pressure is responsible for giving cold-drawn tubes their signature polished finish. It also helps improve tensile strength while altering the pipe dimensions to fit uniform tolerances. This drawing process may get repeated many times to change the shape and tolerance while enhancing elasticity.

Heat may also be applied to the finished product during cold drawing to eliminate internal stresses by improving the microstructural strength.

Language

Language