- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

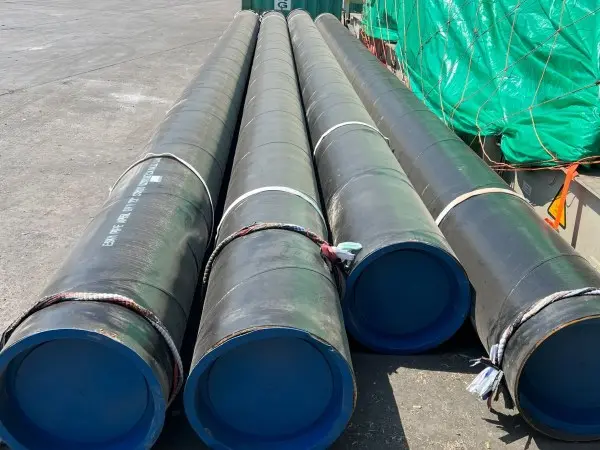

Welded Steel Pipe

SSAW/SAWH Steel Pipe

Out Diameter: 219mm-3620mm

Wall Thickness: 5mm-25.4mm

Length: 3m-12m

Test: Chemical component analysis, mechanical properties(ultimate tensile strength, yield strength, elongation), technical properties(flattening test, bending test, blow test, impact test), exterior size inspection, hydrostatic test, pneumatic test, ultrasonic testing (ut), x-ray test.

Surface: Lightly oiled, hot dip galvanized, electro galvanised, black, bare, varnish coating/antirust oil, protective coatings(coal tar epoxy; fusion bond epoxy, 3-layers pe)

Ends: Beveled Ends, Square Cut, With LTC/STC/BTC/VAM Connection

Delivery: Within 30 days and Depends on your order quantity

Packing: In Bulk, Ends Protector on Both Sides, Waterproof Materials Wrapped

Usage: Used for low pressure liquid delivery, such as water, gas, and oil.

Standard

Specification

SSAW steel pipe, also known as spiral submerged arc welded pipe, is a spiral welded steel pipe produced by double-sided submerged arc welding. Spiral welded pipes are formed using narrower sheets or hot rolled coils, which greatly reduces their production costs. The spiral welding process allows the production of large diameter pipes suitable for transporting large quantities of oil and gas.

Advantages:

SSAW steel pipe can be produced in longer length (maximum length up to 50 meters) compared to lsaw steel pipes

Due to its spiral seam ssaw pipe has an accurate diameter accuracy and strength

The sizes are adjustable & can be tailored to end-users requirement

Uses:

transporting liquids, low-pressure applications, piling pipe, under ocean water application, water lines, pipe bridge, oil & gas, drainage projects, construction piling, irrigation, boiler manufacturing, sewage treatment, thermal industry, road & highways, retaining walls, trestle, seawalls, cofferdams, harbor structure

Specification&Standard

|

ASTM A53 |

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

API 5L |

Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

|

A252 |

Standard Specification for Welded and Seamless Steel Pipe Piles |

|

A500 |

Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

|

BS EN10219-1 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivert conditions |

|

BS EN10219-2 |

Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties |

Chemical Analysis and Mechanical Properties

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Si |

Mn |

P |

S |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

||

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

335 |

335 |

|

B |

0.26 |

- |

1.20 |

0.030 |

0.030 |

415 |

415 |

|

|

X42 |

0.26 |

- |

1.30 |

0.030 |

0.030 |

415 |

415 |

|

|

X46 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

435 |

435 |

|

|

X52 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

460 |

460 |

|

|

X56 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

490 |

490 |

|

|

X60 |

0.26 |

- |

1.40 |

0.030 |

0.030 |

520 |

520 |

|

|

X65 |

0.26 |

- |

1.45 |

0.030 |

0.030 |

535 |

535 |

|

|

X70 |

0.26 |

- |

1.65 |

0.030 |

0.030 |

570 |

570 |

|

|

API 5L PSL2 |

B |

0.22 |

0.45 |

1.20 |

0.025 |

0.015 |

415 |

415 |

|

X42 |

0.22 |

0.45 |

1.30 |

0.025 |

0.015 |

415 |

415 |

|

|

X46 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

435 |

435 |

|

|

X52 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

460 |

460 |

|

|

X56 |

0.22 |

0.45 |

1.40 |

0.025 |

0.015 |

490 |

490 |

|

|

X60 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

520 |

520 |

|

|

X65 |

0.12 |

0.45 |

1.60 |

0.025 |

0.015 |

535 |

535 |

|

|

X70 |

0.12 |

0.45 |

1.70 |

0.025 |

0.015 |

570 |

570 |

|

|

X80 |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

625 |

625 |

|

|

ASTM A53 |

A |

0.25 |

0.10 |

0.95 |

0.050 |

0.045 |

330 |

330 |

|

B |

0.30 |

0.10 |

1.20 |

0.050 |

0.045 |

415 |

415 |

|

|

ASTM A252 |

1 |

- |

- |

- |

0.050 |

- |

345 |

345 |

|

2 |

- |

- |

- |

0.050 |

- |

414 |

414 |

|

|

3 |

- |

- |

- |

0.050 |

- |

455 |

455 |

|

|

EN10217-1 |

P195TR1 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P195TR2 |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

|

P235TR1 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P235TR2 |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265TR1 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

P265TR2 |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-2 |

P195GH |

0.13 |

0.35 |

0.70 |

0.025 |

0.020 |

320 |

320 |

|

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10217-5 |

P235GH |

0.16 |

0.35 |

1.20 |

0.025 |

0.020 |

360 |

360 |

|

P265GH |

0.20 |

0.40 |

1.40 |

0.025 |

0.020 |

410 |

410 |

|

|

EN10219-1 |

S235JRH |

0.17 |

- |

1.40 |

0.040 |

0.040 |

360 |

360 |

|

S275JOH |

0.20 |

- |

1.50 |

0.035 |

0.035 |

410 |

410 |

|

|

S275J2H |

0.20 |

- |

1.50 |

0.030 |

0.030 |

410 |

410 |

|

|

S355JOH |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

470 |

470 |

|

|

S355J2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

|

S355K2H |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

470 |

470 |

|

Process

Spiral steel pipe (SSAW) is a spiral seam steel pipe made of strip steel coils as raw materials, often extruded and formed by automatic double-wire double-sided submerged arc welding. The spiral steel pipe feeds the strip steel into the welded pipe unit. After rolling by multiple rollers, the strip steel is gradually rolled up to form a round tube blank with an open gap. The reduction of the squeeze roller is adjusted to control the weld gap at 1~ 3mm, and make both ends of the welding joint flush.

Language

Language