- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Long Radius Elbow vs Short Radius: Key Differences, Applications, and Selection Guide

When designing or installing a piping system, choosing the right type of elbow is critical for efficiency, safety, and durability. Among the most commonly used fittings are long radius elbow vs short radius elbows. Although both serve the same fundamental purpose—changing the direction of flow—they differ significantly in geometry, pressure drop, and application suitability. This guide will help you understand the differences and decide which one best fits your project.

What Is a Long Radius Elbow?

A long radius elbow (often abbreviated as LR elbow) has a bend radius equal to 1.5 times the pipe diameter. This gradual curve allows for a smoother flow path, minimizing turbulence and pressure loss.

Key Characteristics:

· Bend Radius: 1.5 × pipe diameter

· Flow Performance: Low resistance and reduced pressure drop

· Applications: Oil & gas pipelines, chemical processing plants, HVAC systems, and situations where space allows longer bends

What Is a Short Radius Elbow?

A short radius elbow (SR elbow) has a bend radius equal to the pipe diameter (1.0D). This creates a sharper turn and requires less installation space, but it comes with higher fluid resistance.

Key Characteristics:

· Bend Radius: 1.0 × pipe diameter

· Flow Performance: Higher resistance and increased pressure loss compared to LR elbows

· Applications: Compact installations, low-pressure systems, and cases where space or cost constraints are critical

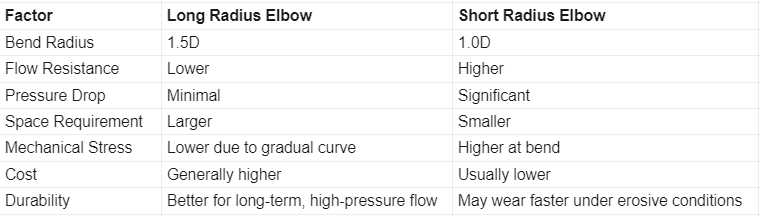

Long Radius Elbow vs Short Radius: A Detailed Comparison

How to Choose Between Long Radius and Short Radius Elbows

When deciding between long radius elbow vs short radius, consider the following factors:

1. Available Space – If space is limited, short radius elbows are often the only option.

2. Flow Efficiency – For systems requiring smooth, uninterrupted flow, long radius elbows are preferred.

3. Operating Pressure – In high-pressure applications, long radius elbows are safer and more durable.

4. Cost Considerations – Short radius elbows are cheaper but may lead to higher maintenance costs over time.

5. Industry Standards – Check ASME, ASTM, or DIN standards for dimensional and material requirements.

Common Industries Using Long and Short Radius Elbows

· Oil & Gas: Long radius elbows dominate due to high flow rates and pressure demands.

· Chemical & Petrochemical: Long radius elbows help reduce erosion and corrosion.

· Power Generation: Both types are used depending on space and flow requirements.

· HVAC & Plumbing: Short radius elbows are common where space constraints exist.

Conclusion

Understanding the differences between long radius elbow vs short radius is crucial for engineers, designers, and contractors. Long radius elbows provide smoother flow, lower stress, and better performance in high-pressure systems, while short radius elbows offer compact solutions where space or budget is limited. By balancing technical needs, space availability, and long-term costs, you can select the right elbow to optimize your piping system.

Language

Language