- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Difference Between Industrial Pipe Fittings and Oil & Gas Pipe Fittings

When it comes to large-scale projects, selecting the right pipe fittings is critical. While many people assume all fittings are the same, there are important differences between industrial pipe fittings and oil & gas pipe fittings. Understanding these distinctions helps engineers, procurement specialists, and project managers ensure safety, efficiency, and compliance with global standards.

In this article, we’ll explore the key differences, applications, and factors to consider when choosing pipe fittings oil and gas projects compared to general industrial usage.

What Are Pipe Fittings?

Pipe fittings are essential components used to connect, control, or redirect the flow of fluids and gases through a piping system. They come in various types, including:

· Elbows

· Tees

· Couplings

· Reducers

· Caps and plugs

While these fittings are used across multiple industries, their requirements differ based on application environments.

What Are Industrial Pipe Fittings?

Industrial pipe fittings are commonly used in industries such as chemical processing, water treatment, HVAC, power plants, and food & beverage. Their primary features include:

· Designed for moderate pressure and temperature conditions

· Materials often include stainless steel, copper, PVC, or brass

· Compliance with general industrial standards (e.g., ANSI, DIN, ISO)

· Lower risk exposure compared to oil and gas

These fittings are generally sufficient for operations where the transported media is less hazardous or operates at lower extremes.

What Are Oil & Gas Pipe Fittings?

Oil & gas pipe fittings are specifically engineered for the demanding conditions of the oil and gas industry. These applications involve high pressures, extreme temperatures, corrosive environments, and flammable substances. Key characteristics include:

· High-Strength Materials: Typically made of carbon steel, alloy steel, or duplex stainless steel for superior durability.

· Pressure & Temperature Resistance: Designed to withstand extreme conditions offshore and onshore.

· Corrosion Resistance: Enhanced coatings or materials to resist crude oil, natural gas, and chemicals.

· Stringent Standards: Must comply with industry-specific certifications such as API (American Petroleum Institute), ASTM, or ASME.

· Safety-Critical: Failures could lead to severe environmental and safety hazards.

In short, oil and gas pipe fittings are built to meet stricter safety, reliability, and performance demands.

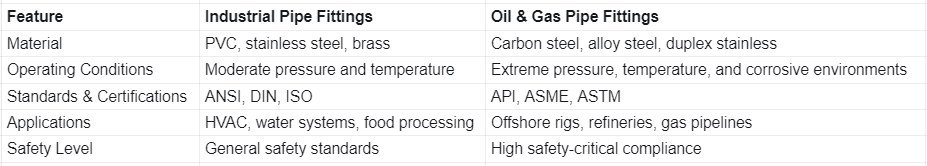

Key Differences Between Industrial and Oil & Gas Pipe Fittings

Why Choosing the Right Pipe Fitting Matters

In oil and gas, the wrong fitting can result in leaks, costly downtime, or even catastrophic accidents. Choosing oil & gas pipe fittings ensures:

· Compliance with international safety regulations

· Longer service life in extreme environments

· Reduced maintenance costs

· Improved reliability in mission-critical operations

For industrial projects, standard fittings are often sufficient, but for oil and gas, specialized solutions are non-negotiable.

Conclusion

The main difference between industrial pipe fittings and oil & gas pipe fittings lies in the level of engineering, material quality, and compliance with strict industry standards. While industrial fittings are suitable for moderate applications, pipe fittings oil and gas must perform under some of the harshest conditions in engineering.

If your project involves petroleum, natural gas, or refinery operations, always ensure you source certified, high-quality oil and gas pipe fittings from trusted manufacturers. The right choice enhances safety, reliability, and long-term performance.

Language

Language