- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Flange&Pipe Fittings

ASTM A234 Pipe Fittings

ASTM A234 is standard specification for wrought carbon steel & alloy steel pipe fittings which covers seamless and welded types.

ASTM A234 pipe fittings are available in latest revision of ASME b16.9, b16.11, mss-sp-79, mss-sp-83, mss-sp-95, and mss-sp-97. Also widely used in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures. The grades are ASTM a234 wpb, wpc, wp5, wp9, wp91, wp11, wp12 and wp22.

Standard

Specification

What is WPB Meaning?

W = Weldable / Wrought

P = Related To P Number Of Alloy Material

B = Refer To Minimum Yield Of Material

Heat Treatment:

Hot-formed A234 WPB and WPC pipe fittings finished at temperature in excess of 1800°F[980°C] shall be subsequently annealed, normalized, or normalized and tempered.

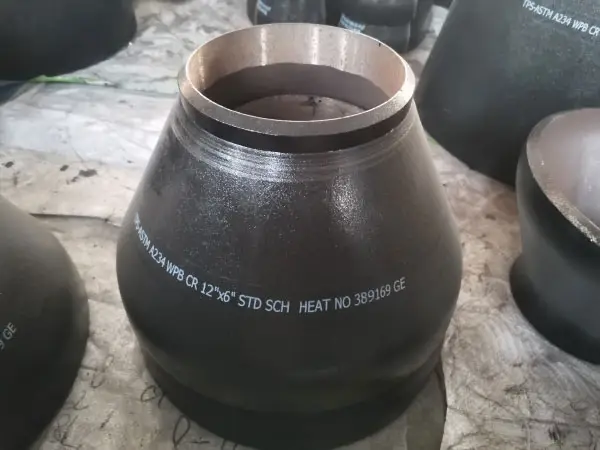

The A234 WPB butt-welding pipe fittings include elbow, bend, tee, reducer, end cap, cross, lap joint stub end and nipple.

Chemical Properties:

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

|

ASTM A234 WPB |

0.3 |

0.1 min |

0.29-1.06 |

0.05 |

0.058 |

0.4 |

0.4 |

0.15 |

|

ASTM A234 WPC |

0.35 |

0.1 min |

0.29-1.06 |

0.05 |

0.058 |

0.4 |

0.4 |

0.15 |

|

ASTM A234 WP5 CL1 |

0.15 |

0.5 |

0.3-0.6 |

0.04 |

0.03 |

4-6 |

|

0.44-0.65 |

|

ASTM A234 WP5 CL3 |

0.15 |

0.5 |

0.3-0.6 |

0.04 |

0.03 |

4-6 |

|

0.44-0.65 |

|

ASTM A234 WP9 CL1 |

0.15 |

1 |

0.3-0.6 |

0.03 |

0.03 |

8-10 |

|

0.9-1.1 |

|

ASTM A234 WP9 CL3 |

0.15 |

1 |

0.3-0.6 |

0.03 |

0.03 |

8-10 |

|

0.9-1.1 |

|

ASTM A234 WP91 |

0.08-0.12 |

0.2-0.5 |

0.3-0.6 |

0.02 |

0.01 |

8-9.5 |

0.4 |

0.85-1.05 |

|

ASTM A234 WP11 CL1 |

0.05-0.15 |

0.5-1 |

0.3-0.6 |

0.03 |

0.03 |

1-1.5 |

|

0.44-0.65 |

|

ASTM A234 WP11 CL2 |

0.05-0.2 |

0.5-1 |

0.3-0.8 |

0.04 |

0.04 |

1-1.5 |

|

0.44-0.65 |

|

ASTM A234 WP11 CL3 |

0.05-0.2 |

0.5-1 |

0.3-0.8 |

0.04 |

0.04 |

1-1.5 |

|

0.44-0.65 |

|

ASTM A234 WP12 CL1 |

0.05-0.2 |

0.6 |

0.3-0.8 |

0.045 |

0.045 |

0.8-1.25 |

|

0.44-0.65 |

|

ASTM A234 WP12 CL2 |

0.05-0.2 |

0.6 |

0.3-0.8 |

0.045 |

0.045 |

0.8-1.25 |

|

0.44-0.65 |

|

ASTM A234 WP22 CL1 |

0.05-0.15 |

0.5 |

0.3-0.6 |

0.04 |

0.04 |

1.9-2.6 |

|

0.87-1.13 |

|

ASTM A234 WP22 CL3 |

0.05-0.15 |

0.5 |

0.3-0.6 |

0.04 |

0.04 |

1.9-2.6 |

|

0.87-1.13 |

Mechanical Properties:

|

Grade |

T.S (min) |

Y.S (min) |

EL (min) |

HB (max) |

|

ASTM A234 WPB |

415-655 (Mpa) |

240 (Mpa) |

22 % |

197 |

|

ASTM A234 WPC |

485-655 (Mpa) |

275 (Mpa) |

22 % |

197 |

|

ASTM A234 WP5 CL1 |

415-585 (Mpa) |

205 (Mpa) |

22 % |

217 |

|

ASTM A234 WP5 CL3 |

520-690 (Mpa) |

310 (Mpa) |

22 % |

217 |

|

ASTM A234 WP9 CL1 |

415-585 (Mpa) |

205 (Mpa) |

22 % |

217 |

|

ASTM A234 WP9 CL3 |

520-690 (Mpa) |

310 (Mpa) |

22 % |

217 |

|

ASTM A234 WP91 |

585-760 (Mpa) |

415 (Mpa) |

20 % |

248 |

|

ASTM A234 WP11 CL1 |

415-585 (Mpa) |

205 (Mpa) |

22 % |

197 |

|

ASTM A234 WP11 CL2 |

485-655 (Mpa) |

275 (Mpa) |

22 % |

197 |

|

ASTM A234 WP11 CL3 |

520-690 (Mpa) |

310 |

22 % |

197 |

|

ASTM A234 WP12 CL1 |

415-585 (Mpa) |

220 |

22 % |

197 |

|

ASTM A234 WP12 CL2 |

485-655 (Mpa) |

275 |

22 % |

197 |

|

ASTM A234 WP22 CL1 |

415-585 (Mpa) |

205 |

22 % |

197 |

|

ASTM A234 WP22 CL3 |

520-690 (Mpa) |

310 |

22 % |

197 |

Process

Heating: The raw material is heated to a temperature that softens it and makes it malleable. The temperature varies depending on the type of material being used. Heating is typically done using a furnace or induction heating equipment.

Forging: The heated metal is then placed in a forging press, where it is compressed and shaped using high-pressure and specialized dies. Forging presses can be hydraulic, mechanical, or pneumatic depending on the size and complexity of the product being manufactured.

Trimming: After the forging process, the excess material is trimmed off to create a finished product. Trimming can be done using a variety of tools including saws, grinders, and shears.

Machining: If necessary, the forged pipe fittings may undergo further machining to create specific shapes or features. Machining is typically done using lathes, mills, or drilling machines.

Inspection: The finished fittings are inspected to ensure they meet quality standards and specifications. Inspection can be done using a variety of tools including calipers, micrometers, and ultrasonic testing equipment.

Language

Language