- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Manufacturing Process of Long Radius Elbows: Hot Forming, Cold Bending, and Mandrel Methods

1. Introduction

A long radius elbow is one of the most common fittings used in piping systems to change the direction of flow while minimizing pressure loss. Compared with a short radius elbow, it has a radius equal to 1.5 times the nominal pipe diameter (1.5D), offering smoother flow and reduced turbulence. Understanding the manufacturing process of long radius elbows is critical for engineers, quality inspectors, and procurement professionals who need to ensure mechanical integrity, dimensional accuracy, and compliance with international standards such as ASME B16.9 or MSS-SP-75.

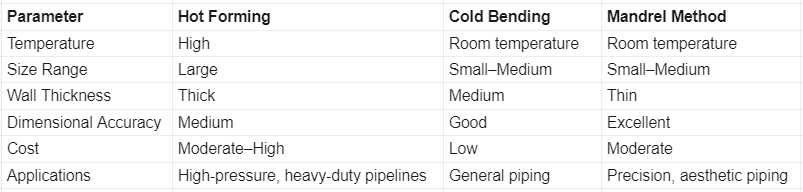

This article explains the three primary manufacturing processes used in the industry—hot forming, cold bending, and mandrel methods—and highlights their advantages, limitations, and applications.

2. Hot Forming Process

2.1 Process Overview

Hot forming is the most widely used method for manufacturing seamless elbows, especially in large diameters and thick-wall applications. The process involves heating a pipe segment to a high temperature (typically 850–1100°C for carbon steel) and then shaping it over a die using a hydraulic press or forming machine.

2.2 Key Steps

1. Pipe Cutting: Cut the straight pipe to a predetermined length based on the required elbow radius and angle (usually 45°, 90°, or 180°).

2. Heating: The pipe piece is heated uniformly in a furnace to improve ductility.

3. Forming: The hot pipe is pressed or pushed over a die and mandrel to achieve the desired radius and curvature.

4. Heat Treatment: After forming, the elbow undergoes normalizing or quenching and tempering to restore mechanical properties.

5. Finishing & Inspection: The elbow is trimmed, beveled, and dimensionally checked according to the standard.

2.3 Advantages

· Suitable for large-diameter and high-thickness elbows.

· Produces uniform wall thickness and excellent mechanical strength.

· Applicable to various materials including carbon steel, alloy steel, and stainless steel.

2.4 Limitations

· High energy consumption and longer production cycles.

· Requires heavy equipment and skilled operators.

3. Cold Bending Process

3.1 Process Description

Cold bending is typically used for long radius elbow production in small to medium diameters. Unlike hot forming, this method shapes the elbow at room temperature without heating the pipe. Specialized bending machines with mechanical or hydraulic force are used to curve the pipe around a fixed radius.

3.2 Technical Steps

1. Insert the pipe into a bending machine equipped with a former or roller.

2. Apply gradual force to achieve the target radius and angle.

3. Check ovality, wall thinning, and spring-back after bending.

3.3 Benefits

· Faster production and lower energy cost.

· Excellent surface finish with minimal oxidation.

· Suitable for materials sensitive to heat treatment (e.g., certain stainless steels).

3.4 Drawbacks

· Wall thinning on the outer curve can occur, limiting use in high-pressure systems.

· Requires careful control of bending radius and strain to prevent cracking.

4. Mandrel Bending Method

4.1 Overview

The mandrel method combines cold bending with an internal support (mandrel) to control deformation during the bending process. The mandrel supports the internal wall of the pipe, minimizing flattening and wall thinning. This technique is ideal for precision long radius elbow manufacturing where dimensional accuracy is critical.

4.2 Process Steps

1. Insert a flexible or segmented mandrel into the pipe.

2. Bend the pipe around a die while maintaining the mandrel’s position.

3. Remove the mandrel after bending and perform dimensional checks.

4.3 Advantages

· Excellent control of ovality and wall thickness.

· High dimensional accuracy and surface quality.

· Preferred for stainless steel and thin-wall elbows used in chemical, HVAC, and food industries.

4.4 Limitations

· Mandrel setup requires precision and maintenance.

· Less suitable for large-diameter heavy-wall pipes.

5. Quality Control and Standards

Regardless of the forming method, quality assurance is essential to guarantee the elbow meets design and safety requirements. Common inspection methods include:

· Dimensional Inspection: Check center-to-end, radius, and wall thickness per ASME B16.9 tolerances.

· Non-Destructive Testing (NDT): Perform radiography, ultrasonic, or magnetic particle tests to detect internal flaws.

· Hydrostatic Testing: Verify pressure resistance and leak tightness.

· Visual and Surface Inspection: Confirm smoothness and absence of scale, cracks, or dents.

6. Choosing the Right Manufacturing Method

7. Conclusion

Selecting the right manufacturing process for a long radius elbow depends on several factors such as material grade, pipe diameter, wall thickness, and performance requirements.

· Hot forming is ideal for large, heavy-duty elbows.

· Cold bending offers cost-effective production for standard systems.

· Mandrel bending ensures superior precision and smooth internal flow.

By understanding these manufacturing techniques, engineers and procurement specialists can make better technical and commercial decisions to ensure piping reliability and compliance.

8. Get Expert Support

If you are looking for the most suitable long radius elbow for your project, our engineering team is ready to assist you.

We provide customized solutions based on your design standards, pressure ratings, and material requirements — ensuring you get the perfect fit for your piping system.

Contact us anytime for professional consultation, technical support, or a detailed quotation on long radius elbows and other pipe fittings.

Language

Language