- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Industry News

Galvanized Seamless Steel Pipe vs. Galvanized Steel Pipe: Key Differences Explained

When choosing piping materials for industrial and construction applications, understanding the difference between galvanized seamless steel pipe and standard galvanized steel pipe is crucial. Both offer corrosion resistance, but their manufacturing processes, structural integrity, and performance vary significantly.

In this article, we’ll compare:

· Manufacturing processes

· Corrosion resistance & durability

· Strength and pressure handling

· Cost and applications

1. Manufacturing Process: How They Are Made

Galvanized Seamless Steel Pipe

· Made from seamless steel pipe (no welded seams)

· Typically uses hot-dip galvanization, resulting in a thicker, more uniform zinc coating

· More resistant to corrosion due to the absence of weld lines

Galvanized Steel Pipe (Welded)

· Starts as welded steel pipe, then undergoes galvanization

· The welding seam can be a weak point for corrosion over time

· Uses hot-dip galvanizing (acid cleaning, flux treatment, then zinc coating)

Key Takeaway: The galvanized seamless steel pipe has no welded joints, making it structurally stronger and more corrosion-resistant.

2. Corrosion Resistance & Durability

Galvanized Seamless Steel Pipe

· Thicker zinc layer due to hot-dip galvanizing

· No weld seams means fewer weak points for rust

· Longer lifespan, ideal for harsh environments

Galvanized Steel Pipe (Welded)

· Zinc coating is uniform but less durable at weld points

· More prone to corrosion at the welded seam over time

· Still provides good protection but may require more maintenance

Best for:

· Seamless → High-corrosion environments (marine, chemical, oil & gas)

· Welded → General water supply, fencing, low-pressure systems

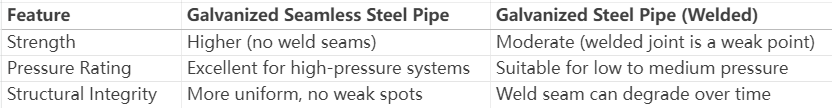

3. Strength & Pressure Handling

Why It Matters:

· Seamless pipes are preferred for fire sprinklers, gas transmission, and high-pressure hydraulics.

· Welded pipes are cost-effective for plumbing, HVAC, and drainage.

4. Cost Comparison & Applications

Galvanized Seamless Steel Pipe

· Higher cost due to complex manufacturing

· Used in:

o High-pressure gas & oil pipelines

o Fire protection systems

o Chemical processing plants

Galvanized Steel Pipe (Welded)

· More affordable for budget-conscious projects

· Common uses:

o Water supply lines

o Fencing & handrails

o Low-pressure HVAC systems

Which Should You Choose?

· For critical, high-pressure, or corrosive environments → Galvanized seamless steel pipe

· For general construction, plumbing, and low-cost projects → Standard galvanized steel pipe

5. Industry Standards & Quality Assurance

Both types must meet:

· ASTM A53 (Standard for welded & seamless steel pipe)

· ASTM A106 (High-temperature seamless pipes)

· ISO 1461 (Hot-dip galvanizing standards)

Pro Tip: Always check certification to ensure compliance with safety regulations.

Final Verdict: Which One Wins?

· For durability & high performance → Galvanized seamless steel pipe

· For budget-friendly projects → Galvanized steel pipe (welded)

If your project demands longevity, high strength, and corrosion resistance, investing in galvanized seamless steel pipe is the smarter choice.

Language

Language