- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Industry News

Hot Bending vs Cold Bending: Common Pipe Bending Techniques Compared

When working with metal pipes, choosing the right bending technique is crucial for structural integrity, cost efficiency, and performance. Two of the most widely used methods are hot bending vs cold bending, each with distinct advantages depending on the application.

In this guide, we’ll explore the key differences between hot bending vs cold bending, their pros and cons, and how to determine which method is best for your project.

1. What is Hot Bending?

Hot bending involves heating the pipe to a high temperature (typically between 1,600°F and 2,200°F / 870°C–1,200°C) before shaping it. This process softens the metal, making it easier to bend without cracking.

When to Use Hot Bending:

✔ Thick-walled or large-diameter pipes (e.g., oil & gas pipelines).

✔ High-strength alloys (e.g., stainless steel, titanium).

✔ Tight bend radii (R ≤ 3D, where D is the pipe diameter).

✔ Preventing material stress & cracking in brittle metals.

Pros of Hot Bending:

✅ Reduces material hardening and springback.

✅ Allows tighter bends without pipe collapse.

✅ Better for high-strength or corrosion-resistant alloys.

Cons of Hot Bending:

❌ Higher energy and labor costs.

❌ Risk of oxidation (scale formation).

❌ Requires skilled operators and safety precautions.

2. What is Cold Bending?

Cold bending shapes pipes at room temperature using mechanical force, such as press bending, rotary draw bending, or roll bending.

When to Use Cold Bending:

✔ Thin-walled or small-diameter pipes (e.g., automotive exhausts).

✔ Carbon steel or ductile materials.

✔ Faster, more cost-effective production.

Pros of Cold Bending:

✅ Lower operational costs (no heating required).

✅ Faster production for high-volume jobs.

✅ Minimal surface oxidation.

Cons of Cold Bending:

❌ Risk of material work-hardening.

❌ Limited to larger bend radii (R ≥ 3D).

❌ May require annealing for stress relief.

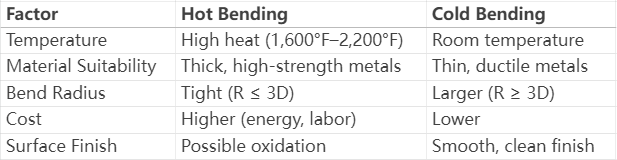

3. Hot Bending vs Cold Bending: Key Differences

The choice between hot bending vs cold bending depends on material type, bend complexity, and budget.

4. Which Method Should You Choose?

Choose Hot Bending If:

· Working with thick-walled or high-strength pipes.

· Needing tight-radius bends without deformation.

· Handling stainless steel, titanium, or nickel alloys.

Choose Cold Bending If:

· Bending thin-walled or carbon steel pipes.

· Prioritizing cost efficiency and speed.

· Requiring a smooth surface finish.

5. Conclusion

Both hot bending vs cold bending have unique strengths, and the best method depends on your project’s requirements. Hot bending excels in heavy-duty applications with challenging materials, while cold bending is ideal for cost-effective, high-volume production.

By understanding these techniques, engineers and fabricators can optimize pipe bending for durability, efficiency, and performance.

Looking for High-Quality Pipe Bends? Contact Us for Expert Solutions!

Whether you need precision hot bending for heavy-duty applications or cost-effective cold bending for high-volume production, our team delivers reliable, high-performance pipe bends tailored to your needs.

Get in touch today for custom solutions!

Language

Language