- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

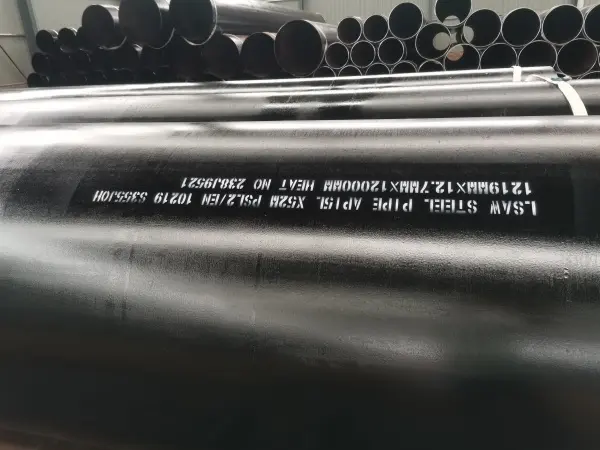

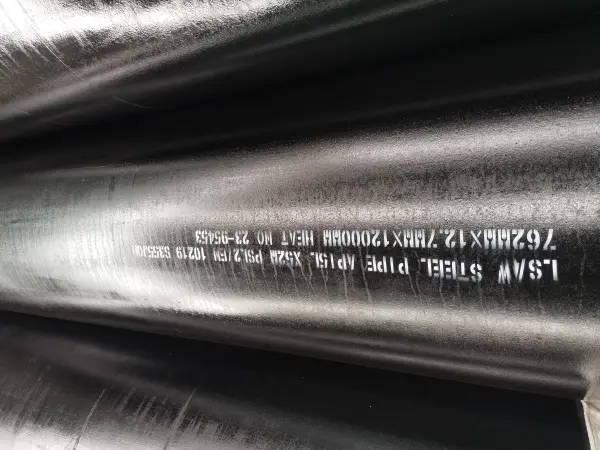

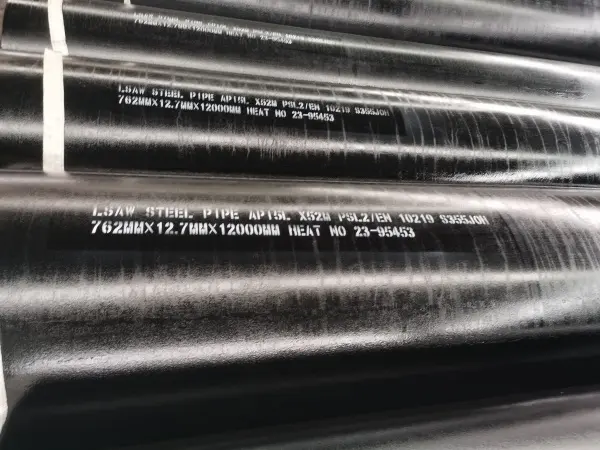

Welded Steel Pipe

EN 10219 Steel Pipe

Size: Out diameter:21mm-610mm; Wall thickness:2mm-16mm

Application: Civil engineering, bridge engineering, water engineering

Ends: Plain end/Beveled, protected by plastic caps on both ends, grooved, threaded and coupling, etc.

Surface: Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Grade: S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H

Standard

Specification

This part of this European Standard specifies technical delivery conditions for hot finished hollow sections of circular, square, rectangular or elliptical forms and applies to hollow sections formed hot, with or without subsequent heat treatment, or formed cold with subsequent heat treatment to obtain equivalent metallurgical conditions to those obtained in the hot formed product.

EN 10219: Cold formed welded structural hollow sections of non-alloy and fine grain steels.

|

Material |

Min Yield Strength |

Tensile Strength (N/mm2) |

Min. Elongation (%) |

||

|

Thickness in mm |

|||||

|

t<16 |

16>t<40 |

t<3 |

3>t<40 |

t<40 |

|

|

S235JRH |

235 |

225 |

360-510 |

340-470 |

24 |

|

S275J0H |

275 |

265 |

430-580 |

410-560 |

20 |

|

S275J2H |

275 |

265 |

430-580 |

410-560 |

20 |

|

S355J0H |

355 |

345 |

510-680 |

490-630 |

20 |

|

S355J2H |

355 |

345 |

510-680 |

490-630 |

20 |

Manufacturing Tolerances:

|

Characteristic |

Round Hollow Sections |

Square and Rectangular Hollow Sections |

|

Outside Dimension |

± 1% with min ± 0.5mm and max ± 10mm |

± 1% with min of ± 0.5mm |

|

Thickness (T) |

T≤5mm: ±10% |

T≤5mm: ±10% |

|

T>5mm: ± 0.5mm |

T>5mm: ± 0.5mm |

|

|

Out-of-Roundness |

2% |

- |

|

Convexity |

- |

Max .8% with min 0.5mm |

|

Squareness of side |

- |

90° ± 1° |

|

External Corner Profile |

- |

T≤6mm: 1.6T to 2.4T |

|

- |

6 |

|

|

- |

T,10: 2.4T to 3.6T |

|

|

Twist |

- |

2mm plus 0.5mm/m |

|

Straightness |

0.2% of total |

0.15% of total |

|

Mass |

±6% on individual length |

|

Weldablity of EN 10219 Pipe:

Weldable steels are specified in this European standard. EN 1011-1 and EN 1011-2 specify the main standards for welding products under this European standard.

When welding these products, the greatest danger is the development of cold cracking in the welded zone as the product thickness, strength level, and CEV rise. Cold cracking is a result of a combination of the following factors:

elevated diffusible hydrogen levels in the weld metal;

a brittle structure in the heat-affected zone;

and large tensile stress concentrations in the welded joint.

Chemical Composition:

|

Steel Grade |

Ytpe of De-oxidation a |

% by Mass, Maximum |

||||||

|

Steel Name |

Steel Number |

C |

Si |

Mn |

P |

S |

N b |

|

|

S235JRH |

1.0039 |

FF |

0.17 |

– |

1.40 |

0.040 |

0.040 |

0.009 |

|

S275J0H |

1.0149 |

FF |

0.20 |

– |

1.50 |

0.035 |

0.035 |

0.009 |

|

S275J2H |

1.0138 |

FF |

0.20 |

– |

1.50 |

0.030 |

0.030 |

– |

|

S355J0H |

1.0547 |

FF |

0.22 |

0.55 |

1.60 |

0.035 |

0.035 |

0.009 |

|

S355J2H |

1.0576 |

FF |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

– |

|

S355K2H |

1.0512 |

FF |

0.22 |

0.55 |

1.60 |

0.030 |

0.030 |

– |

|

A.The deoxidation method is designated as follws: |

||||||||

|

B.The maximum value for nitrogen dose not apply if the chemical composition shows a minimum total Al content of 0.020% with a minimum Al/N ratio of 2:1, or if sufficient other -binding elements are present. The N-binding elements shall be reocrded in the Inspection Document. |

||||||||

Mechanical Properties:

|

Steel Grade |

Minimum Yield |

Tensile Strength Rm |

Minimum elongation |

Minimum Impact |

|||||

|

Steel |

Steel |

Specified Thickness |

Specified Thickness |

Specified Thickness |

at Test Temperature of |

||||

|

≤16 |

> 16 ≤ 40 |

<3 |

≥3 ≤40 |

≤40 |

-20℃ |

0℃ |

20℃ |

||

|

S235JRH a |

1.0039 |

235 |

225 |

360-510 |

360-510 |

24 b |

– |

– |

27 |

|

S275J0H a |

1.0149 |

275 |

265 |

430-580 |

410-560 |

20 c |

– |

27 |

– |

|

S275J2H |

1.0138 |

27 |

– |

– |

|||||

|

S355J0H a |

1.0547 |

355 |

345 |

510-680 |

470-630 |

20 c |

– |

27 |

– |

|

S355J2H |

1.0576 |

– |

– |

– |

|||||

|

S355K2H |

1.0512 |

40 f |

– |

– |

|||||

|

The impact properties are verified only when Option 1.3 is specified |

|||||||||

|

For thicknesses > 3 mm and section sizes D/T < 15 (round) and (B+H)/2T < 12.5 (square and rectangular) the minimum elongation is by 2. For thicknesses > 3 mm the minimum value for elongation is 17 %. |

|||||||||

|

For section size D/T < 15 (circular) and (B+H)/2T < 12.5 (square and rectangular) and minimum elongation is reduced by 2. |

|||||||||

|

For thicknesses < 3 mm see 9.2.2. |

|||||||||

|

For impact properties for reduced section test pieces see 6.7.2 |

|||||||||

|

This value corresponds to 27J at -30℃ (see EN 1993-1-1). |

|||||||||

Language

Language