- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

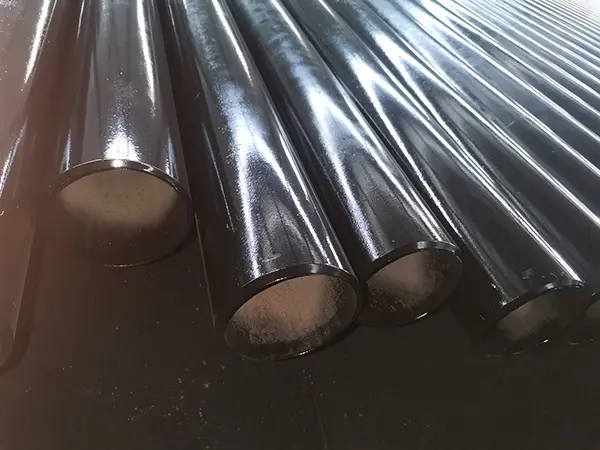

Seamless Steel Pipe

EN 10210 Steel Tube

Surface protection: Black (self coloured uncoated), varnish/oil coating, pre-galvanized, hot dip galvanized

Dimension range: 21.3-914mm

Wall thickness: 0.5mm - 25mm

Ends: Square ends/plain ends (straight cut, saw cut, torch cut), beveled/threaded ends

Packing: Bundle or bulk , wooden case or other seaworthy packing or for the client's requirement

Usage: En10210 seamless non-alloy steel tubes for pressure purposes with specified room temperature properties mainly used as boiler water tube, smoke tube, superheater tube, air preheater tube, and so

Standard

Specification

EN 10210 tube is a low carbon steel tube that is of low cost. The material comes with carbon, silicon, manganese, phosphorus and sulfur in the composition.

The DIN EN 10210 tube Dimensions range in outer diameter, wall thickness and the length. The pipes can come in outer diameters from 21.3mm to 1219.2 mm. The length can vary as single random, double random and custom cut to length sizes.

The EN 10210-2 Pipe suppliers produce the pipes in wall thicknesses 0.5mm to 20mm and the schedules range from sch20 to XXS and heavier. The pipes are hot finished, hollow sections of non alloy and fine grain steel types. The grades vary and each grade has specific mechanical properties.

EN 10210 Pipe has up to 630MPa minimum tensile strength and up to 355MPa minimum yield strength with 22% elongation at break.

The pipes can be made seamless or welded. The EN 10210 Pipe is cold drawn or hot rolled from ingots while the welded pipes are welded from sheets or plates.

The EN 10210-1 seamless steel pipe has higher dimensional accuracy and the EN 10210 S355j2h Steel Pipe is used in sensitive applications such as equipment and tools. The dimensions of the S355j2h EN 10210 Tube is lower than the pipes. The tubes usually range up to 152mm in outer diameter. The EN 10210 seamless steel tube is used in structural applications where extra strength is needed. The square cross sectional provide extra geometric strength to the product.

The EN 10210 tube can be used in oil and gas, petroleum, petrochemical, food production and in power generation applications.

Chemical Composition

|

Element |

Carbon |

Silicon |

Manganese |

Phosphorous |

Sulfur |

|

S355J2H |

Maximum 0.22 |

Maximum 0.55 |

Maximum 1.6 |

Maximum 0.03 |

Maximum 0.03 |

EN 10210 s355j2h material Mechanical Properties Table

|

Specification |

EN10210 S355J2H |

|

Yield Strength ReH Min, N/mm2 = T ≤ 16mm |

355 |

|

Tensile Strength Rm N/mm2 = 3 ≤ T ≤ 100 MM |

470 – 630 |

|

Impact properties Minimum Ave energy at -20°C |

27 |

|

Minimum Elongation % T ≤ 40mm on gauge length 5.65. √S0 |

22 |

Heat Treatment of EN 10210 s355j2h steel pipe

|

Hot Forming |

Heat Treatment |

|||

|

Temperature °C |

Cooling Type |

Normalizing |

Stress relieving |

Cooling Type |

|

700 To 750 |

Air |

850 To 950°C |

580 To 630°C |

Air |

Check Dimensions and Size Chart of S355J2H EN 10210 pipe and rectangular tube

S355J2H EN 10210 Pipes Sizes

|

1/8 Inch IPS(.405 Inch Outer Diameter) |

3 1/2 Inch IPS( 4.000 Inch Outer Diameter) |

|

3/8 Inch IPS(.675 Inch Outer Diameter) |

5 Inch IPS( 5.563 Inch Outer Diameter) |

|

Schedule 40, 80 |

Schedule 10, 40, 80, 160, XXH |

|

1/4 Inch IPS(.540 Inch Outer Diameter) |

4 Inch IPS(4.500 Inch Outer Diameter) |

|

Schedule 10, 40, 80 |

Schedule 10, 40, 80, 160, XXH |

|

Schedule 10, 40, 80, 160, XXH |

Schedule-40 (.375) |

|

Schedule 10, 40, 80 |

Schedule 10, 40, 80, 160, XXH |

|

1/2 Inch IPS(.840 Inch Outer Diameter) |

6 Inch IPS(6.625 Inch Outer Diameter) |

|

Schedule 5, 10, 40, 80, 160, XXH |

Schedule 5, 10, 40, 80, 120, 160, XXH |

|

3/4 Inch IPS(1.050 Inch Outer Diameter) |

8 ” IPS(8.625 Inch Outer Diameter) |

|

Schedule 10, 40, 80, 160, XXH |

Schedule 5, 10, 40, 80, 120, 160, XXH |

|

1 Inch IPS:(1.315′ Outer Diameter) |

10 Inch IPS(10.750 Inch Outer Diameter) |

|

Schedule 5, 10, 40, 80, 160, XXH |

Schedule 10, 20, 40, 80 (.500), TRUE 80(.500) |

|

2 Inch IPS(2.375 Inch Outer Diameter) |

16 Inch IPS(16.000 Inch Outer Diameter) |

|

1-1/4 Inch IPS(1.660 Inch Outer Diameter) |

12 Inch IPS(12.750 Inch Outer Diameter) |

|

1-1/2 Inch IPS(1.900 Inch Outer Diameter) |

14 Inch IPS(14.000 Inch Outer Diameter) |

|

Schedule 10, 40, 80, 160, XXH |

Schedule10 (.188), Schedule40 (.375) |

|

Schedule 10, 40, 80, 160, XXH |

Schedule 10, 20, 40(.375), TRUE40(.406), Schedule80(.500) |

|

Schedule 10, 40, 80, 160, XXH |

Schedule10(.188), Schedule40(.375) |

|

2 1/2 Inch IPS(2.875 Inch Outer Diameter) |

18 Inch IPS (18.000 Inch Outer Diameter) |

|

3 Inch IPS( 3.500 Inch Outer Diameter) |

Schedule 5, 10, 40, 80, 160, XXH |

EN 10210 Grade S355J2H Hot Finished CHS Tube Sizes Chart

|

Wall Thickness |

Outer Diameter Sizes in Inch |

|

.010 |

1/16, 1/8, 3/16 |

|

.020 |

1/16, 1/8, 3/16, 1/4, 5/16, 3/8 |

|

.120 |

1/2, 5/8, 3/4, 7/8, 1, 1 1/4, 1 1/2, 2, 2 1/4, 2 1/2, 3 |

|

.083 |

1/4, 3/8, 1/2, 5/8, 3/4, 7/8, 1, 1 1/4, 1 1/2, 1 5/8, 1 7/8, 2, 2 1/2,3 |

|

.012 |

1/8 |

|

.016 |

1/8, 3/16 |

|

.028 |

1/8, 3/16, 1/4, 5/16, 3/8, 1/2, 3/4, 1, 1 1/2, 2 |

|

.035 |

1/8, 3/16, 1/4, 5/16, 3/8, 7/16, 1/2, 16, 5/8, 3/4, 7/8, 1, 1 1/4, 1 1/2, 1 5/8, 2, 2 1/4 |

|

.134 |

1 |

|

.049 |

3/16, 1/4, 5/16, 3/8, 1/2, 16, 5/8, 3/4, 7/8, 1, 1 1/8, 1 1/4, 1 1/2, 1 5/8, 2, 2 1/4 |

|

.065 |

1/4, 5/16, 3/8, 1/2, 16, 5/8, 3/4, 7/8, 1, 1 1/4, 1 1/2, 1 5/8, 1 3/4, 2, 2 1/2, 3 |

|

.095 |

1/2, 5/8, 1, 1 1/4, 1 1/2, 2 |

|

.109 |

1/2, 3/4, 1, 1 1/4, 1 1/2, 2 |

|

.250 |

3 |

|

.125 |

3/4, 1, 1 1/4, 1 1/2, 2, 3, 3 1/4 |

|

.375 |

3 1/2 |

Leading Supplier of Carbon Steel S355j2h En 10210 Pipe. View Tolerance Chart of EN 10210-1 Grade S355J2H Structural Hollow Sections

S355j2h EN 10210 tube Tolerance

|

Execution |

Size Range |

Outer Diameter Tolerance |

Tolerance |

|

Hot-rolled Tube |

OD – 80 Outer Diameter > 80 Wall < 12 Wall = 12 |

± 0.4 ± 0.5 % of Outer Diameter |

± 0.7 ± (5 % x wall thickness + 0.1 |

|

Cold Worked tubecold rolled or cold drawn |

OD < 40 Outer Diameter 40 - 80 Outer Diameter > 80 Wall Thickness< 6 Wall Thickness6 = 8 Wall Thickness > 8 |

+ 0.30/- 0 *+ 0.35/- 0 *+ 0.40/- 0 |

± 0.30 ± 0.35 ± 0.40 |

|

Hot rolled peeled tube |

All sizes Wall < 12 Wall = 12 |

+ 0.25/- 0 mm |

± 0.8 ± (5 % x wall thickness+ 0.2) |

Length Tolerance of EN 10210 S355J2H Carbon Steel Seamless Pipe

|

Component length in MM |

Outer Diameter 30 To 100 in MM |

Outer Diameter 100 To 254 in MM |

|

600 To 1200 |

+ 3.0/- 0 |

+ 4.0/- 0 |

|

10 To 100 |

+ 1.0/- 0 |

+ 2.0/- 0 |

|

1200 to 5000 |

+ 5.0/- 0 |

+ 6.0/- 0 |

|

100 To 600 |

+ 2.0/- 0 |

+ 3.0/- 0 |

Language

Language