- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

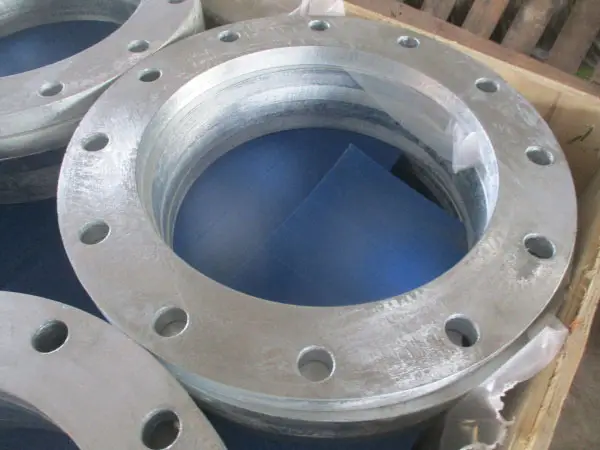

Flange&Pipe Fittings

ASTM A182 Pipe Fittings

ASTM A182 is standard specification for forged or rolled alloy & stainless steel flanges, forged fittings, and valves for high-temperature service.

They are widely used in petrochemical, oil & gas, power generation, chemicals, and paper manufacturing. We use the forged steel fittings and flanges to connect tubes in variety of industrial applications such as plumbing, heating, fluid distribution, air pressure lines and air conditioning.

Standard

Specification

Scope

This specification covers forged low-alloy and stainless steel piping components for use in pressure systems. Included are flanges, fittings, valves and similar parts to specified dimensions or to dimensional standards. Products made to this specification are limited to a maximum weight of 10,000 lb.

Chemical Properties %

|

Grade |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

|

ASTM A182 F304 |

0.08 |

2 |

0.045 |

0.03 |

1 |

8.0-11.0 |

18.0-20.0 |

|

|

ASTM A182 F304H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

8.0-11.0 |

18.0-20.0 |

|

|

ASTM A182 F304L |

0.03 |

2 |

0.045 |

0.03 |

1 |

8.0-13.0 |

18.0-20.0 |

|

|

ASTM A182 F304N |

0.08 |

2 |

0.045 |

0.03 |

1 |

8.0-10.5 |

18.0-20.0 |

|

|

ASTM A182 F304LN |

0.03 |

2 |

0.045 |

0.03 |

1 |

8.0-10.5 |

18.0-20.0 |

|

|

ASTM A182 F309H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

12.0-15.0 |

22.0-24.0 |

|

|

ASTM A182 F310 |

0.25 |

2 |

0.045 |

0.03 |

1 |

19.0-22.0 |

24.0-26.0 |

|

|

ASTM A182 F310H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

19.0-22.0 |

24.0-26.0 |

|

|

ASTM A182 F310MoLN |

0.03 |

2 |

0.03 |

0.015 |

0.4 |

21.0-23.0 |

24.0-26.0 |

2.0-3.0 |

|

ASTM A182 F316 |

0.08 |

2 |

0.045 |

0.03 |

1 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

ASTM A182 F316H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

ASTM A182 F316L |

0.03 |

2 |

0.045 |

0.03 |

1 |

10.0-15.0 |

16.0-18.0 |

2.0-3.0 |

|

ASTM A182 F316N |

0.08 |

2 |

0.045 |

0.03 |

1 |

11.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

ASTM A182 F316LN |

0.03 |

2 |

0.045 |

0.03 |

1 |

11.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

ASTM A182 F316Ti |

0.08 |

2 |

0.045 |

0.03 |

1 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

ASTM A182 F317 |

0.08 |

2 |

0.045 |

0.03 |

1 |

11.0-15.0 |

18.0-20.0 |

3.0-4.0 |

|

ASTM A182 F317L |

0.03 |

2 |

0.045 |

0.03 |

1 |

11.0-15.0 |

18.0-20.0 |

3.0-4.0 |

|

ASTM A182 F321 |

0.08 |

2 |

0.045 |

0.03 |

1 |

9.0-12.0 |

17.0-19.0 |

|

|

ASTM A182 F321H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

9.0-12.0 |

17.0-19.0 |

|

|

ASTM A182 F347 |

0.08 |

2 |

0.045 |

0.03 |

1 |

9.0-13.0 |

17.0-20.0 |

|

|

ASTM A182 F347H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

9.0-13.0 |

17.0-20.0 |

|

|

ASTM A182 F348 |

0.08 |

2 |

0.045 |

0.03 |

1 |

9.0-13.0 |

17.0-20.0 |

|

|

ASTM A182 F348H |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

9.0-13.0 |

17.0-20.0 |

|

Mechanical Properties

|

Grade |

Tensile Strength (Mpa) |

Yield point (Mpa) |

Elongation (%) |

Reduction (%) |

|

ASTM A182 F304 |

515 |

205 |

30 |

50 |

|

ASTM A182 F304L |

485 |

170 |

30 |

50 |

|

ASTM A182 F316 |

515 |

205 |

30 |

50 |

|

ASTM A182 F316L |

485 |

170 |

30 |

50 |

|

ASTM A182 F321 |

515 |

205 |

30 |

50 |

Process

Process: The low-alloy ferritic steels shall be made by the open-hearth, electric-furnace or basic-oxygen process with the option of separate degassing and refining processes in each case. The stainless steels shall be melted by one of the following processes: Electric-furnace (with the option of separate degassing and refining processes), vacuum-furnace or one of the former followed by vacuum or electroslag-consumable remelting.

Heat Treatment: After hot working, forgings shall be cooled to a temperature below 1000 °F (538 °C) prior to heat treating in accordance with the requirements of ASTM A182. The low-alloy steels and ferritic and martensitic stainless steels shall be heat treated in accordance with the requirements of ASTM A182.

Language

Language