- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

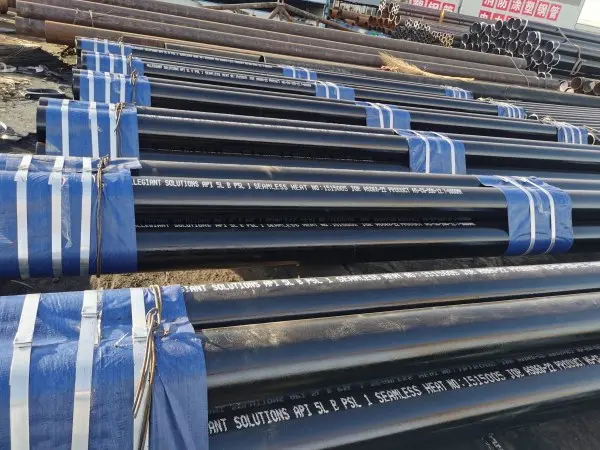

Seamless Steel Pipe

ASTM A106 Steel Pipe

Outside Diameter: 42.2mm——273mm

Wall Thickness: 1.25mm-50mm

Length: 3-12 meters, Support customization

Manufacture: Hot-finished or cold-drawn

Heat Treatment: Hot-finished pipe need not be heat treated. cold-drawn pipe shall be heat treated after the final cold draw pass at a temperature of 1200°f (650°c) or higher.

Surface Process: Bright, Polished, Black

Standard

Specification

ASTM A106 seamless pipes (also known as ASME SA106 pipes) are commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers and ships. These pipes must carry fluids that exhibit higher temperature and pressure levels And gas.ASTM A106 pipe includes three grades, A106 grade a, A106 grade b, and A106 grade c.

About ASTM A106 Grade B:

ASTM A106 Grade B Pipe (also known as ASME SA106 GR.B pipes) is used in power plants, boilers, petrochemical plants, oil and gas refineries, and ships where the piping must transport hot or cold liquids and gases under high pressures and temperatures. A106 GR. B Carbon Steel Seamless Pipes, A106 Gr B Sch 40 pipe, ASTM A106 Grade B Pipe Suppliers is available in various weights, sizes, and black and galvanized grades both seamless and electric welded. ASTM A106 Grade B Pipe sizes, less than 2" is it normally delivered as a cold drawn product. 2" and up are usually hot finished.

About ASTM A106 Grade C:

ASTM A106 Grade C Pipe (also known as ASME SA106 GR.C pipes) is a carbon-manganese steel pipe for high-temperature large-diameter boilers and superheaters. Its chemical composition is simple and similar to 20G carbon steel, but its carbon and manganese content is higher, so its yield strength is about 12% higher than that of 20G, and its plasticity and toughness are not bad. The steel has a simple production process and good cold and hot workability. Using it to replace 20G headers (economizer, water wall, low-temperature superheater and reheater header) can reduce the wall thickness by about 10%, which can save material costs, reduce welding workload, and improve headers The stress difference at start-up.

ASTM A106 Chemical Composition:

|

steel grade |

c, max.% |

mn % |

p, max |

s, max |

si, min |

cr, max |

cu, max |

mo, max |

ni, max |

v, max |

|

grade a |

0.25 |

0.27 - 0.93 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

grade b |

0.30 |

0.29 - 1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

grade c |

0.35 |

0.29 - 1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

ASTM A106 Mechanical Property:

|

grade |

tenssile test mpa or n/mm2 |

remarks (similar to jis) |

|

|

min. yield point |

tensile strength |

||

|

gr a |

205 |

330min |

(stpg370) |

|

gr b |

240 |

415min |

(stpg410) |

|

gr c |

275 |

485min |

(stpg480) |

A106 Dimension Tolerances:

|

pipe type |

pipe sizes |

tolerances |

|

|

cold drawn |

od |

≤48.3mm |

±0.40mm |

|

≥60.3mm |

±1%mm |

||

|

wt |

±12.5% |

||

A106 Steel Pipe Testing Requirements

Hydrostatic Testing: In hydrostatic testing, A106 seamless steel pipe samples are subjected to test pressure at 60% of specified minimum yield strength, at ambient temperatures; pressure test is maintained for at least five seconds. Maximum test pressures shall not exceed 2,500 psi for NPS3 steel pipe, or 2,800 psi for all larger sizes.Mechanical Testing: A106 seamless pipe NPS 8 and larger are weighed in lots; larger sizes are weighed by length. Flattening tests are required on A106 pipe NPS 2-1/2 and larger; cold bend testing is required for A106 pipe NPS 2 and smaller.

Process

The steel shall be killed steel, with the primary melting process being open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining. If secondary melting, using electroslag remelting or vacuum-arc remelting is subsequently employed, the heat shall be defined as all of the ingots remelted from a single primary heat.

Steel cast in ingots or strand cast is permissible. When steels of different grades are sequentially strand cast, identifi- cation of the resultant transition material is required. The producer shall remove the transition material by any estab- lished procedure that positively separates the grades.

For pipe nps 11⁄2 [dn 40] and under, it shall be permissible to furnish hot finished or cold drawn.

Unless otherwise specified, pipe nps 2 [dn 50] and over shall be furnished hot finished. When agreed upon between the manufacturer and the purchaser, it is permissible to furnish cold-drawn pipe.

Language

Language