- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

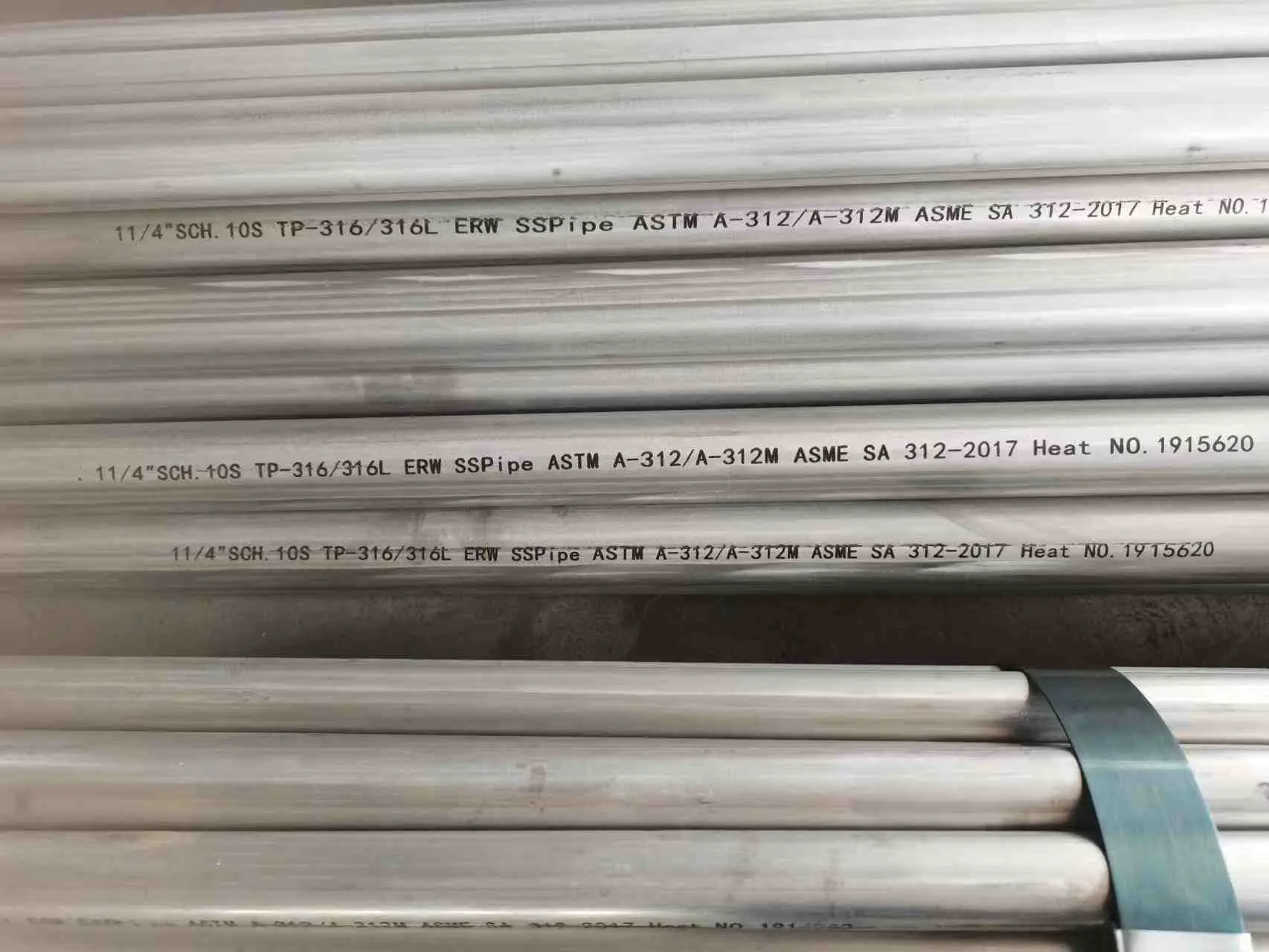

Stainless Steel Pipe

316 Stainless Steel Pipe

Standard: ASTM A312, ASME SA312, ASTM A269, ASTM A270

Common use grades: 316, 316L, 316H, 316Ti, 316N, 316LN

Diameters: From 1/8 inch to 30 inch.

Wall thickness: SCH 10S, 40S, 80S

Length: 20ft, 40ft, Single Random Length, Double Random Length and Customized

Applications:

Chemical: chemical containers, pressure vessels, and industrial equipment

Water treatment: woven or welded screens for water filtration

Pulp and paper: used in paper machines to avoid iron contamination.

Automotive: threaded fasteners, springs, and furnace parts

Medical: medical equipment and orthopedic implants

Dental: dental implants, orthodontic appliances, and various dental instruments

Semiconductor: semiconductor manufacturing equipment and cleanroom environments

Food processing: food preparation surfaces, equipment, and appliances

Standard

Specification

316 stainless steel is anaustenitic chromium-nickel stainless steel that contains added molybdenum, which increases its resistance to corrosion and oxidation. This grade is particularly effective against chloride and marine environments, making it ideal for more challenging conditions. 316 stainless steel pipes offer excellent toughness, even at cryogenic temperatures, and are known for their superiorwelding properties. They are widely used in applications such as food processing equipment, pharmaceutical and medical devices, chemical and petrochemical processing, marine applications, and in any setting where high corrosion resistance is essential. This versatility makespolished 316 ss a preferred choice for demanding industrial applications.

Grade 316 is the standard molybdenum-bearing grade, second in overall volume production to 304 amongst theaustenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments.

Mechanical Properties

|

Temper |

Annealed |

Cold worked (approx. 20%) |

||||

|

Material |

316 |

316L |

|

316 |

316L |

|

|

Tensile Rm |

75 |

70 |

ksi (min) |

102-131 |

ksi (min) |

|

|

Tensile Rm |

515 |

485 |

MPa (min) |

700-900 |

MPa (min) |

|

|

R.p. 0.2% Yield |

30 |

27 |

ksi (min) |

73-102 |

ksi (min) |

|

|

R.p. 0.2% Yield |

205 |

182 |

MPa (min) |

500-700 |

MPa (min) |

|

|

Elongation (2” or 4D gl) |

35 |

% (min) |

40 |

% (min) |

||

Physical Properties (Room Temperature)

|

Specific Heat (0-100°C) |

500 |

J.kg-1.°K-1 |

|

Thermal Conductivity |

16.3 |

W.m -1.°K-1 |

|

Thermal Expansion |

15.9 |

μm/μm/°C |

|

Modulus Elasticity |

193 |

GPa |

|

Electrical Resistivity |

7.4 |

Ohm-cm |

|

Density |

7.99 |

g/cm3 |

Chemical Composition (% by weight)

|

|

316 |

316L |

||

|

Element |

Min |

Max |

Min |

Max |

|

C |

- |

0.08 |

- |

0.035 |

|

Mn |

- |

2 |

- |

2 |

|

Ni |

10 |

14 |

10 |

15 |

|

Cr |

16 |

18 |

16 |

18 |

|

Mo |

2 |

3 |

2 |

3 |

|

S |

- |

0.03 |

- |

0.03 |

|

Si |

- |

1 |

- |

1 |

|

P |

- |

0.045 |

- |

0.045 |

Language

Language