- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Industry News

Is Your Boiler Pipe Insulation Actually Saving You Money or Burning It?

You watch your monthly fuel bills climb higher while your facility's mechanical room feels like a sauna. This excess heat is not just uncomfortable; it is a clear sign that your piping system is hemorrhaging cash. Boiler pipe insulation is a critical thermal barrier that stops heat loss, lowers fuel consumption, and prevents worker injuries. By covering hot pipes with materials like mineral wool or fiberglass, you ensure that thermal energy stays inside the system to heat your process, not the surrounding air.

I often see project managers focus entirely on buying an expensive boiler. They ignore the distribution network. This is a costly mistake. If you do not insulate the lines, you lose the efficiency you paid for.

How Does Lack of Insulation Drain Your Budget?

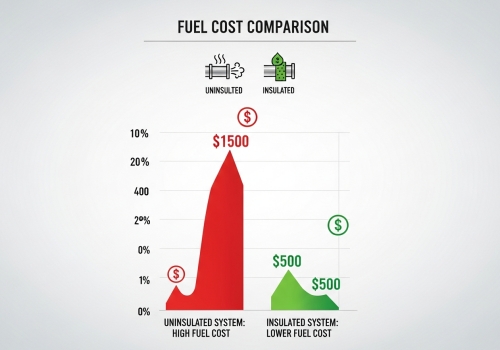

Uninsulated pipes act like radiators that you cannot turn off. They constantly release expensive heat into the atmosphere. This forces your boiler to burn more fuel just to keep up. Without effective boiler pipe insulation, the thermal energy generated by your fuel source escapes before it reaches its destination. This heat loss creates a massive efficiency gap, requiring your system to work overtime and driving up operational costs significantly, often wasting thousands of dollars annually.

I have worked in this industry for 18 years. I have walked into plants where the heat hit me like a wall. That heat represents wasted dollars. The physics are simple. A steam pipe carrying fluid at 350°F running through a room at 70°F has a huge temperature difference. Nature wants to balance this. The heat rushes out of the pipe. Your boiler burns gas or oil to create that heat. When it escapes through the pipe wall, you are paying to heat the air in the plant. This is useless. It does not help your production. In fact, it hurts it because your cooling system has to work harder to remove that heat. It is a double loss. I advise my clients at Finego Steel to look at the "Payback Period." This is the time it takes for the insulation savings to cover the installation cost. Usually, it is very short, often less than a year. If you leave pipes bare, you are choosing to lose money every single day. You must treat heat as a product you bought. Do not throw it away. Here is a look at the financial impact of heat loss:

| Cost Factor | Uninsulated Pipe | Insulated Pipe |

|---|---|---|

| Fuel Consumption | Very High | Optimized |

| HVAC Load | Increased (to cool the room) | Minimal |

| Equipment Wear | High (Boiler works harder) | Low |

| Maintenance Cycles | Frequent | Standard |

| Profit Margin | Reduced | Protected |

Can Insulation Prevent Workplace Injuries Effectively?

Hot pipes are a silent trap for your workers. A split-second accidental touch can result in a third-degree burn. This creates a dangerous environment and a huge liability for your company. Installing proper insulation reduces the surface "touch temperature" of your piping to safe levels, typically below 120°F. This protective layer ensures that employees working near steam lines or hot water pipes are safe from burns, while also lowering the ambient room temperature to prevent heat exhaustion.

Safety is not just a rule; it is a necessity. As a manager, I know that one accident can stop a project. I remember a case where a maintenance worker brushed his arm against a bare steam valve. It was a bad burn. The project stopped for an investigation. We lost time and money. Boiler pipe insulation acts as a shield. The steam inside might be deadly hot, but the outer jacket remains cool enough to touch. This is vital in tight spaces. Mechanical rooms are often cramped. Workers have to squeeze between pipes to read gauges or turn valves. If those pipes are bare, it is a hazard. Also, consider the ambient heat. If you have hundreds of feet of hot pipe, the room temperature creates heat stress. Workers get tired faster. They make mistakes. Their focus drops. By keeping the heat in the pipe, you keep the room comfortable. This improves focus and productivity. It is a simple change that improves the daily life of your team.

Which Insulation Materials Work Best for High Temperatures?

You cannot use standard foam from a local hardware store for industrial boilers. The heat will melt it instantly. You need specialized materials designed to handle extreme thermal stress. The best insulation for industrial boiler pipes involves high-temperature materials like mineral wool, calcium silicate, or removable PTFE blankets. These materials withstand temperatures exceeding 500°F, resist fire, and offer durability that standard residential fiberglass wraps cannot provide in a harsh industrial setting.

Choosing the right material is a sourcing challenge. I often see people try to save money upfront with cheap fiberglass. This is a mistake. Traditional fiberglass is okay for warm water, but for high-pressure steam, it has flaws. The biggest issue is maintenance. Boiler systems need regular checks. Valves and flanges leak. If you use permanent fiberglass, you have to cut it off to fix the pipe. Once you cut it, it is trash. Most crews do not have the budget to replace it immediately. So the pipe stays bare. I recommend removable insulation blankets for valves and flanges. These use straps or Velcro. You can take them off, do the repair, and put them back on. They use materials like ceramic fiber or silicone cloth. They cost more upfront but save money over five years. For long straight runs, calcium silicate or rigid mineral wool is better. It is hard and can take a beating. Material Selection Guide:

| Material | Max Temp | Key Benefit | Best Application |

|---|---|---|---|

| Fiberglass | ~850°F | Low Cost | General heating lines |

| Mineral Wool | ~1200°F | Fire Resistant | High-temp steam piping |

| Calcium Silicate | ~1200°F | Structural Strength | High-traffic areas |

| Removable Blankets | ~550°F+ | Reusable | Valves, Flanges, Pumps |

Why Is the Steel Pipe Underneath Just as Important as the Jacket?

You can buy the most expensive insulation in the world, but it is useless if the pipe underneath fails. Poor quality steel leads to leaks that ruin the insulation from the inside out. Insulation hides the pipe surface, making it impossible to see corrosion until it is too late. Therefore, starting with high-quality, corrosion-resistant steel pipes from Finego Steel is essential to prevent "Corrosion Under Insulation" (CUI) and ensure the long-term integrity of your boiler system. This is a point many buyers miss. I call it the "out of sight, out of mind" problem. When you cover a pipe, you create a hidden environment. If moisture gets in, it stays there. If the steel pipe has a weak surface or poor chemical composition, it will rust quickly. This is called CUI. It is a leading cause of leaks in the oil and gas industry. At Finego Steel, we understand this risk. We supply SSAW and seamless steel pipes that are perfectly round. Why does roundness matter? If a pipe is oval, the insulation does not fit tight. Air pockets form. Condensation gathers in those pockets. That water eats the steel. We ensure our pipes meet strict ASTM and API standards. We check the wall thickness and surface finish. We also offer pipes with special anti-corrosion coatings that work under insulation. As a supplier since 1996, we know that the pipe is the foundation. You build the insulation system on top of the pipe. If the foundation is weak, the system fails. We help you choose the right steel grade to handle the heat and the pressure, ensuring your investment lasts.

Conclusion

Effective insulation lowers costs and ensures safety, but it relies on a strong foundation. At Finego Steel, we provide the premium boiler pipes necessary to support your insulation system and secure your facility's efficiency.

- Prev : How does the lsaw steel pipe manufacturing process guarantee quality for your project?

- Next : No matching information found

Language

Language