- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

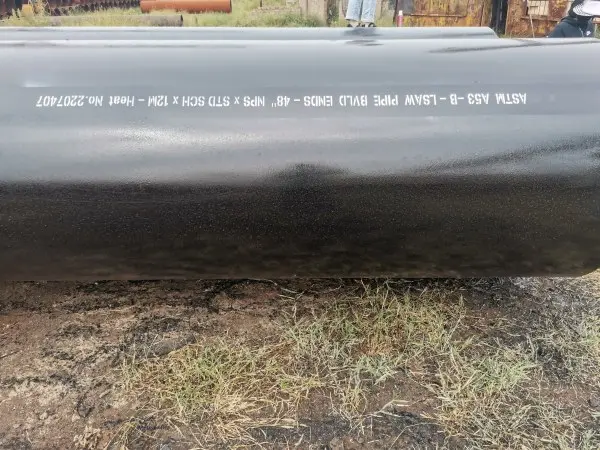

Welded Steel Pipe

ASTM A53 Welded Steel Pipe

ASTM A53 (ASME SA53) carbon steel pipe is a specification that covers seamless and welded black and hot-dipped galvanized steel pipe in nps 1/8″ to nps 26. ASTM A53 steel pipe is intended for pressure and mechanical applications and is also acceptable for ordinary uses in steam, water, gas, and air lines.

Sizes: 1/2” to 20”

Thickness: Schedule 10, 40, STD, XS, to XXS

Ends: Plain, Beveled, Threaded

Length: 20 ft, 40 ft, customized

Coating: 3PE, FBE, Varnished, Black, Zinc Coated

Standard

Specification

Applications:

ASTM A53 Steel Pipe is vastly used in construction sites and underground transportation.

For example: it can be used to draw water from the ground as fluid pipe. It is used as pipeline pipes for gas and oil transmission as well as water power station, it is also used as structural steel in machinery parts, after coated with zinc, it is used in wind power plant.

Specification:

|

Specifications |

ASTM A53 ASME SA53 |

|

Dimensions |

ASTM, ASME and API |

|

Size |

1/2" NB to 36" NB |

|

Thickness |

3-12mm |

|

Schedules |

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

|

Type |

Seamless / ERW / Welded / Fabricated |

|

Form |

Round, Hydraulic Etc |

|

Length |

Min 3 Meters, Max18 Meters, or according to customer's requirement |

|

End |

Plain End, Beveled End, Treaded |

Chemical Compostions:

|

ASTM A53 |

Type E |

Type F |

|

|

Chemical Composition |

(electric- |

(furnace- |

|

|

|

Grade A |

Grade B |

Grade A |

|

Carbon max. % |

0.25 |

0.30 |

0.3 |

|

Manganese % |

0.95 |

1.2 |

1.2 |

|

Phosphorous, max. % |

0.05 |

0.05 |

0.05 |

|

Sulfur, max. % |

0.045 |

0.045 |

0.045 |

|

Copper, max.% |

0.40 |

0.40 |

0.4 |

|

Nickel, max. % |

0.40 |

0.40 |

0.4 |

|

Chromium, max. % |

0.40 |

0.40 |

0.4 |

|

Molybdenum, max. % |

0.15 |

0.15 |

0.15 |

|

Vanadium, max. % |

0.08 |

0.08 |

0.08 |

Tensile Requirements for Seamless and Welded ASTM A53 Pipe:

|

Grade ASTM A53 |

Seamless Pipes and Electric-resistance-welded Pipes |

Continuous-Welded Pipes |

|

|

Mechanical Property |

Grade A |

Grade B |

|

|

Tensile Strength, min., psi |

48,000 |

60,000 |

45,000 |

|

Yield Strength, min., psi |

30,000 |

35,000 |

25,000 |

Test Requirements for ASTM A53 Steel Pipes:

|

Test Types |

ASTM A53 Pipe Test Details |

|

Number of Tests Required |

Seamless and Electric-Resistance-Welded — Bending, flattening, tensile on one length of pipe from each lot of 500 lengths or less of a size. |

|

Hydrostatic Testing |

Hydrostatic inspection test pressures for plain end and threaded and coupled pipe are specified. Hydrostatic pressure shall be maintained for not less than 5 seconds for all sizes of seamless and electric-resistance-weld pipe. |

|

Mechanical Tests Specified |

Tensile Test — Transverse required on ERW for NPS 8 and large. Sending Test (Cold) — STD and XS-NPS 2 and under XXS-NPS 1 1/4 and under. |

Language

Language