- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

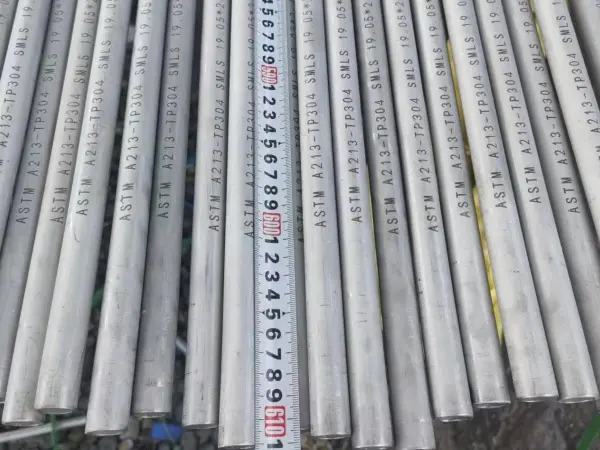

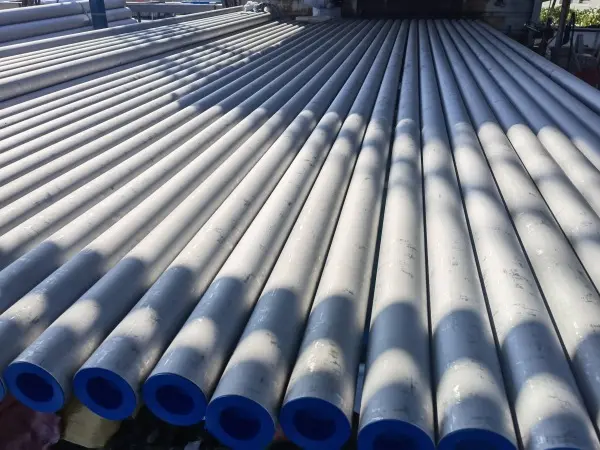

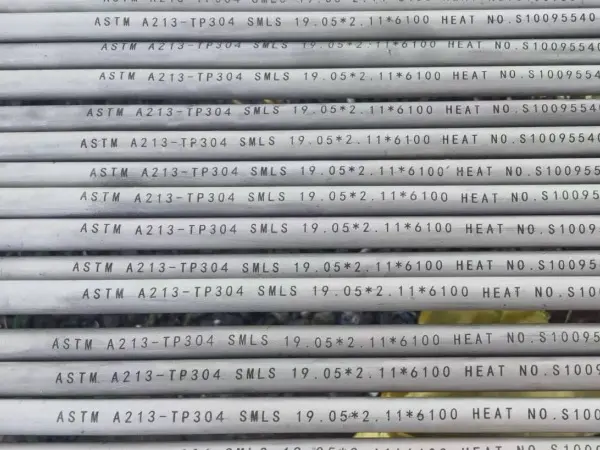

Stainless Steel Pipe

304 Stainless Steel Pipe

Supplying stainless steel pipe(ss) and various kinds of steel pipe.

Our products are manufactured using high quality materials. Customers can avail this range of products from us in different sizes, lengths, and specifications.

To make sure best quality product delivery, we check our offered products on various quality parameters under the direction of our skillful quality inspectors.

ASTM: a312 tp 304 / 304l / 304h / 316 / 316l / 317 / 317l / 321 / 310 / 347 / 904l etc

Others: duplex, super duplex, monel, nickel, inconel, hastelloy

Types: round, square, rectangular

Size: upto 48” nb. (seamless & welded)

Wall Thickness: sch. 5s to sch. xxs

Standard

Specification

Grade 304 is the standard "18/8" stainless; it is the most versatile and most widely used material of seamless stainless steel pipes, available in a wider range of products, forms and finishes than any other. It has excellent forming and welding characteristics. The balanced austenitic structure of Grade 304 enables it to be severely deep drawn without intermediate annealing, which has made this grade dominant in the manufacture of drawn stainless parts such as sinks, hollow-ware and saucepans. for these applications it is common to use special "304DDQ" (Deep Drawing Quality) variants. Grade 304 is readily brake or roll formed into a variety of components for applications in the industrial, architectural, and transportation fields. Grade 304 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

|

Standard |

AISI, ASTM, DIN, JIS, BS, NB, GB |

|

|

Size |

Round |

Outer Diameter: 4mm-2500mm (3/8"-100")

Thickness: 1mm-150mm(SCH10-XXS)

|

|

Square |

Outer Diameter: 4mm*4mm-800mm*800mm

Thickness: 1mm-150mm(SCH10-XXS)

|

|

|

Rectangular |

Outer Diameter: 4mm-2500mm (3/8"-100")

Thickness: 1mm-150mm(SCH10-XXS)

|

|

|

Length |

2m, 3m, 5m, 5.8m, 6m,11.8m, 12m,or as required |

|

|

Tolerance |

1. Outer Diameter: +/- 0.2mm

2. Thickness: +/- 10% OR as customer request

3. Length: +/- 10mm

|

|

|

Surface |

Pickling white, Polished outside, Polished inside and outside, Brushed, Mirrored, Plated, Perforated |

|

304 Stainless Steel Pipes and Tubes Range:

|

304 Stainless Steel Pipe & Tubes Specification |

ASTM A269, ASTM A213, ASTM A312, ASME SA269, ASME SA213, ASME SA312 |

|

304 Stainless Steel Pipe & Tubes Grades |

202, 304, 304L, 304H, 304LN, 309S, 310S, 316, 316L, 316H, 316Ti, 316LN, 317L, 321, 321H, 347, 347H, 904L, SMO 254, ALLOY 254, 6MO, 6MOLY, UNS S31254 ETC. |

|

304 Stainless Steel Pipe & Tubes Type |

Seamless / Welded / ERW / EFW / Cold Draw / Hot Finish / Cold Finish |

|

304 Stainless Steel Pipe & Tubes Outer Diameter Size |

Seamless - 1/2" NB TO 18" NB |

|

304 Stainless Steel Pipe & Tubes Wall Thickness |

Schedule 10 to Schedule 160 (3 mm to 100 mm Thickness) |

|

304 Stainless Steel Pipe & Tubes Length |

01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

|

304 Stainless Steel Pipe & Tubes Ends |

Plain Ends / Beveled Ends |

|

304 Stainless Steel Pipe & Tubes Delivery Conditions |

As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw |

|

304 Stainless Steel Pipe & Tubes Coating |

Electropolish, Mechanical Polish, Satin Finish, PassivateD |

|

304 Stainless Steel Pipe & Tubes Other Testing |

Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiograph HIC Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

|

304 Stainless Steel Pipe & Tubes Dimension |

All Pipes Is Manufactured and Inspected / Tested to the Relevant standards includingASTM And ASME |

|

304 Stainless Steel Pipe & Tubes Value Added Services |

Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

|

304 Stainless Steel Pipe & Tubes Packaging |

Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

|

304 Stainless Steel Pipe & Tubes Shipment & Transportation |

By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

|

304 Stainless Steel Pipe & Tubes Material Test Certificate |

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

Chemical Composition of 304 Stainless Steel Pipes and Tubes:

The Chemical Composition of grade 304 Stainless Steel is outlined in the following table

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

|

304 |

min. |

- |

- |

- |

- |

- |

18.0 |

- |

8.0 |

- |

|

max. |

0.08 |

2.0 |

0.75 |

0.045 |

0.030 |

20.0 |

|

10.5 |

0.10 |

|

|

304L |

min. |

- |

- |

- |

- |

- |

18.0 |

- |

8.0 |

- |

|

max. |

0.030 |

2.0 |

0.75 |

0.045 |

0.030 |

20.0 |

|

12.0 |

0.10 |

|

|

304H |

min. |

0.04 |

- |

- |

-0.045 |

- |

18.0 |

- |

8.0 |

- |

|

max. |

0.10 |

2.0 |

0.75 |

|

0.030 |

20.0 |

|

10.5 |

|

|

Mechanical Properties of 304 Stainless Steel Pipes and Tubes:

The Mechanical Properties of grade 304 Stainless Steel are displayed in the following table.

|

Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

|

|

Rockwell B (HR B) max |

Brinell (HB) max |

||||

|

304 |

515 |

205 |

40 |

92 |

201 |

|

304L |

485 |

170 |

40 |

92 |

201 |

|

304H |

515 |

205 |

40 |

92 |

201 |

|

304H also has a requirement for a grain size of ASTM No 7 or coarser. |

|||||

304 Stainless Steel Pipes and Tubes Physical Properties:

Physical properties of 304 grade stainless steel in the annealed condition

|

|

Density(kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (μm/m/°C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Electrical Resistivity (nΩ.m) |

|||

|

0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

|||||

|

304/L/H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

Specification Comparison For Grade 304 Stainless Steel Pipes and Tubes:

Grade Specifications for 304 grade stainless steel

|

Grade |

UNS No |

Old British |

Euronorm |

Swedish SS |

Japanese JIS |

||

|

BS |

En |

No |

Name |

||||

|

304 |

S30400 |

304S31 |

58E |

1.4301 |

X5CrNi18-10 |

2332 |

SUS 304 |

|

304L |

S30403 |

304S11 |

- |

1.4306 |

X2CrNi19-11 |

2352 |

SUS 304L |

|

304H |

S30409 |

304S51 |

- |

1.4948 |

X6CrNi18-11 |

- |

- |

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted. |

|||||||

304 Stainless Steel Pipes and Tubes Applications:

The grade 304 steel can be made into plates, sheets, and coils to be used in the following:

- Food processing equipment, particularly in beer brewing, milk processing & wine making.

- Kitchen benches, sinks, troughs, equipment and appliances

- Architectural panelling, railings & trim

- Chemical containers, including for transport

- Heat Exchangers

- Woven or welded screens for mining, quarrying & water filtration

- Threaded fasteners

- Springs

Process

1.1. Hot-rolled stainless steel seamless pipes are generally produced on automatic pipe rolling mills. The solid tube is inspected and cleaned of surface defects, cut to the required length, centered on the perforated end of the tube, and then sent to the heating furnace for heating and piercing on the punching machine. When the perforation continues to rotate and advance at the same time, under the action of the roller and the plug, a cavity is gradually formed inside the tube blank, which is called a capillary tube. And then sent to the automated rolling mill to continue rolling. Finally, the whole wall thickness is uniformed for the whole machine, and the diameter is sizing by the sizing machine to meet the specifications. The use of continuous tube rolling mills to produce hot rolled seamless steel tubes is a more advanced method.

1.2. If you want to obtain seamless pipes with smaller size and better quality, cold rolling, cold drawing or a combination of the two methods must be used. Cold rolling is usually carried out on a two-high rolling mill. The steel pipe is rolled in an annular pass formed by a variable cross-section circular hole groove and a stationary tapered plug. Cold drawing is usually carried out on a single-chain or double-chain cold drawing machine of 0.5-100T.

1.3. The extrusion method is to put the heated tube blank in a closed extrusion cylinder, and the perforated rod and the extrusion rod move together to extrude the extruded part of the smaller die hole. This method can produce steel pipes with smaller diameters.

This kind of steel pipe can be divided into two categories: stainless steel seamless steel pipe and stainless steel welded steel pipe (seam pipe). According to the different manufacturing process, it can be: hot-rolled, extruded, cold drawn and cold-rolled. The shape can be divided into round pipes and special-shaped pipes. Round steel pipes are widely used, but there are also some special-shaped stainless steel pipes such as square, rectangular, semicircular, hexagonal, equilateral triangle, and octagonal.

Language

Language