- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

What is FBE Coated Pipe? Complete Guide for Industrial Applications

If you work in the pipeline, oil, gas, or water industry, you may have heard the term FBE coated pipe. Understanding what is FBE coated pipe is essential for engineers, project managers, and procurement professionals aiming for long-lasting, reliable pipelines. This guide covers its applications, benefits, installation tips, and FAQs.

Understanding FBE Coated Pipe

FBE stands for Fusion Bonded Epoxy, a thermosetting powder coating applied to steel pipes to prevent corrosion and improve durability. FBE coated pipe forms a strong, uniform barrier that resists moisture, chemicals, and mechanical damage, making it ideal for industrial pipelines.

FBE Coating Process

1. Surface Preparation: Sandblast to remove rust and contaminants for maximum adhesion.

2. Preheating: Heat the pipe to 200–250°C.

3. Powder Application: Apply epoxy powder electrostatically; use single or multi-layer coatings as needed.

4. Curing: Bake to form a hard, durable layer.

5. Quality Inspection: Check thickness, adhesion, and defects.

Features and Benefits

· Corrosion Resistance: Protects steel from moisture, soil chemicals, and industrial fluids.

· Strong Adhesion: Bonds tightly to steel for long-lasting protection.

· Temperature Resistance: Up to 200°C.

· Mechanical Durability: Resists impact, abrasion, and handling damage.

· Cost-Effective: Lower lifecycle costs than PE or polyurethane coatings.

· Environmentally Friendly: Solvent-free and safe for the environment.

Applications

· Oil and Gas Pipelines: Underground and offshore corrosion protection.

· Water Supply Systems: Ensures safe, clean water transport.

· Petrochemical Plants: Resistant to harsh chemicals.

· Industrial Piping: Suitable for factories, refineries, and processing plants.

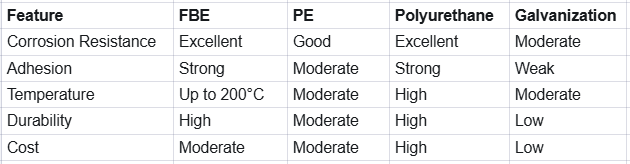

FBE Coated Pipe vs Other Coatings

Installation and Maintenance Tips

· Handle carefully to avoid coating damage.

· Touch up welded areas to maintain protection.

· Inspect using holiday detectors and thickness gauges.

· Repair damaged spots promptly.

FAQ

Q1: Can FBE coated pipes be used offshore?

Yes, they resist corrosion in harsh environments.

Q2: Single-layer vs multi-layer FBE?

Single-layer offers basic protection; multi-layer provides higher resistance in extreme conditions.

Q3: How long do FBE coated pipes last?

20–50 years depending on environment and maintenance.

Q4: Is FBE environmentally safe?

Yes, it’s solvent-free and reduces environmental impact.

Conclusion

So, what is FBE coated pipe? It is a steel pipeline with a fusion bonded epoxy coating that provides excellent corrosion resistance, durability, and cost efficiency. From oil and gas to water supply systems, FBE coated pipes ensure long-term, reliable performance while reducing maintenance costs and protecting the environment.

Language

Language