- No.101 Wanbo 1st Road, Nancun Town, Panyu District, Guangzhou, Guangdong, China

- 0086-020-84886013,84886093,84886091,84886012

- sales@finegosteel.com

Product News

Comparing 321 Stainless Steel Seamless Pipes vs 304 and 316: Which One to Choose?

When it comes to selecting the right stainless steel pipes for industrial or high-performance applications, understanding the differences between 321 stainless steel seamless pipe, 304, and 316 grades is crucial. Each grade has unique properties, advantages, and limitations that can impact performance, durability, and cost. This article will provide a detailed comparison to help you make an informed choice.

1. Overview of Stainless Steel Grades

· 304 Stainless Steel

304 is the most commonly used stainless steel, known for its excellent corrosion resistance and formability. It is widely applied in kitchen equipment, pipelines, and general industrial applications.

· 316 Stainless Steel

316 stainless steel contains molybdenum, which significantly enhances its resistance to corrosion, especially in chloride or marine environments. It is often used in chemical processing, marine applications, and outdoor equipment.

· 321 Stainless Steel

321 stainless steel seamless pipe is stabilized with titanium, which improves its resistance to intergranular corrosion after exposure to high temperatures. This makes it ideal for aerospace, petrochemical, and high-temperature industrial applications.

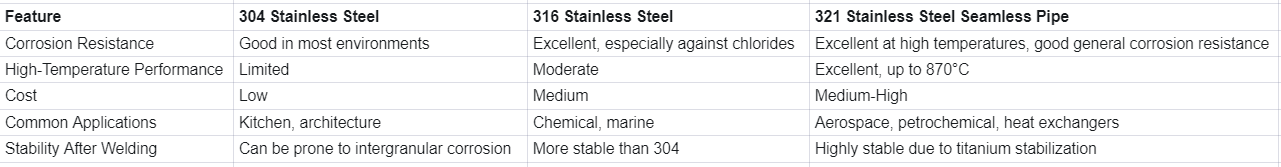

2. Key Differences

3. Advantages of 321 Stainless Steel Seamless Pipe

1. High-Temperature Resistance

The titanium stabilization prevents chromium carbide precipitation during welding, ensuring the pipe maintains strength and corrosion resistance under high temperatures.

2. Seamless Construction

Being seamless, 321 stainless steel seamless pipe offers superior mechanical strength and is less prone to leaks or failures in high-pressure systems compared to welded pipes.

3. Versatile Industrial Use

It is widely used in heat exchangers, gas turbines, exhaust systems, and chemical processing plants where both high-temperature resistance and corrosion resistance are critical.

4. How to Choose Between 304, 316, and 321

· Choose 304 if the application involves general corrosion resistance at moderate temperatures and low cost is a priority.

· Choose 316 for environments exposed to harsh chemicals or marine conditions where superior corrosion resistance is required.

· Choose 321 stainless steel seamless pipe for high-temperature operations, welding-intensive applications, or critical industrial systems that require long-term durability and stability.

5. Conclusion

Selecting the right stainless steel grade can significantly affect the lifespan and performance of your piping system. For high-temperature and critical industrial applications, 321 stainless steel seamless pipe often provides the best combination of corrosion resistance, thermal stability, and mechanical strength. While 304 and 316 are suitable for more general applications, 321 is the optimal choice when durability under extreme conditions is essential.

Language

Language